1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 5497-1985 English PDF (GB/T5497-1985)

GB/T 5497-1985 English PDF (GB/T5497-1985)

Regular price

$115.00

Regular price

Sale price

$115.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 5497-1985: Inspection of grain and oilseeds. Methods for determination of moisture content

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 5497-1985 (Self-service in 1-minute)

Newer / historical versions: GB/T 5497-1985

Preview True-PDF

Scope

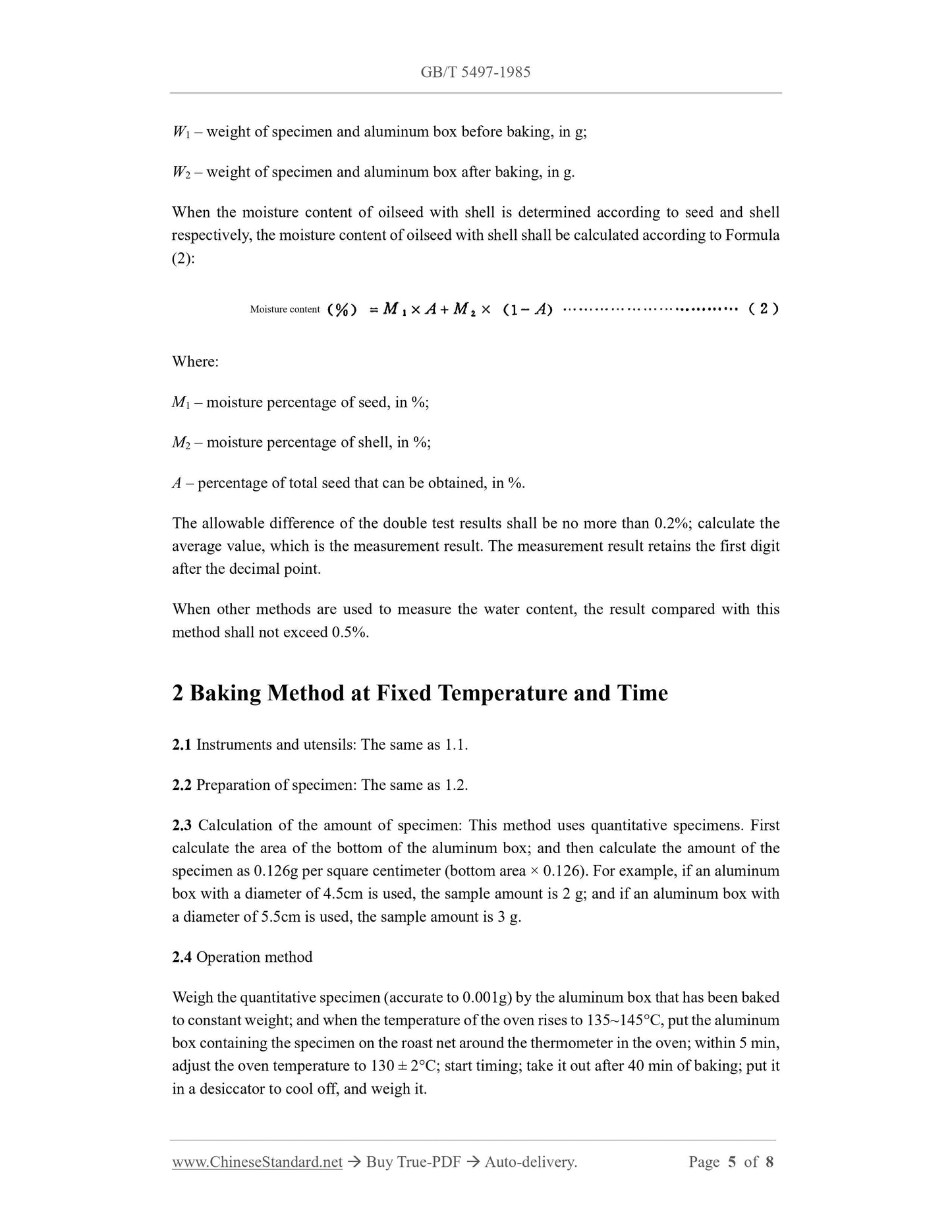

1.1 Instruments and utensils1.1.1 Electric thermostat box;

1.1.2 Analytical balance: 0.001g;

1.1.3 Electric grinder or hand grinder for laboratory use;

1.1.4 Grain screening;

1.1.5 A desiccator equipped with color-changing silica gel (the color-changing silica gel cannot

be used once it turns red, and it shall be dried at 130°C ~140°C until it turns blue before use).

1.1.6 Aluminum box: inner diameter 4.5cm, height 2.0cm.

1.2 Preparation of specimen

Take a certain sample from the average sample; and prepare the specimen according to the

method specified in the table below.

W1 – weight of specimen and aluminum box before baking, in g;

W2 – weight of specimen and aluminum box after baking, in g.

When the moisture content of oilseed with shell is determined according to seed and shell

respectively, the moisture content of oilseed with shell shall be calculated according to Formula

(2):

Where:

M1 – moisture percentage of seed, in %;

M2 – moisture percentage of shell, in %;

A – percentage of total seed that can be obtained, in %.

The allowable difference of the double test results shall be no more than 0.2%; calculate the

average value, which is the measurement result. The measurement result retains the first digit

after the decimal point.

When other methods are used to measure the water content, the result compared with this

method shall not exceed 0.5%.

Basic Data

| Standard ID | GB/T 5497-1985 (GB/T5497-1985) |

| Description (Translated English) | Inspection of grain and oilseeds. Methods for determination of moisture content |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | X10 |

| Classification of International Standard | 67.04 |

| Word Count Estimation | 3,329 |

| Date of Issue | 11/2/1985 |

| Date of Implementation | 7/1/1986 |

| Issuing agency(ies) | National Bureau of Standards |

| Summary | This standard applies to the determination of commodity grain, oil water content. |

Share