1

/

of

10

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 5312-2009 English PDF (GB/T5312-2009)

GB/T 5312-2009 English PDF (GB/T5312-2009)

Regular price

$85.00

Regular price

Sale price

$85.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 5312-2009: Carbon and carbon-manganese steel seamless steel tubes and pipes for ship

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 5312-2009 (Self-service in 1-minute)

Newer / historical versions: GB/T 5312-2009

Preview True-PDF

Scope

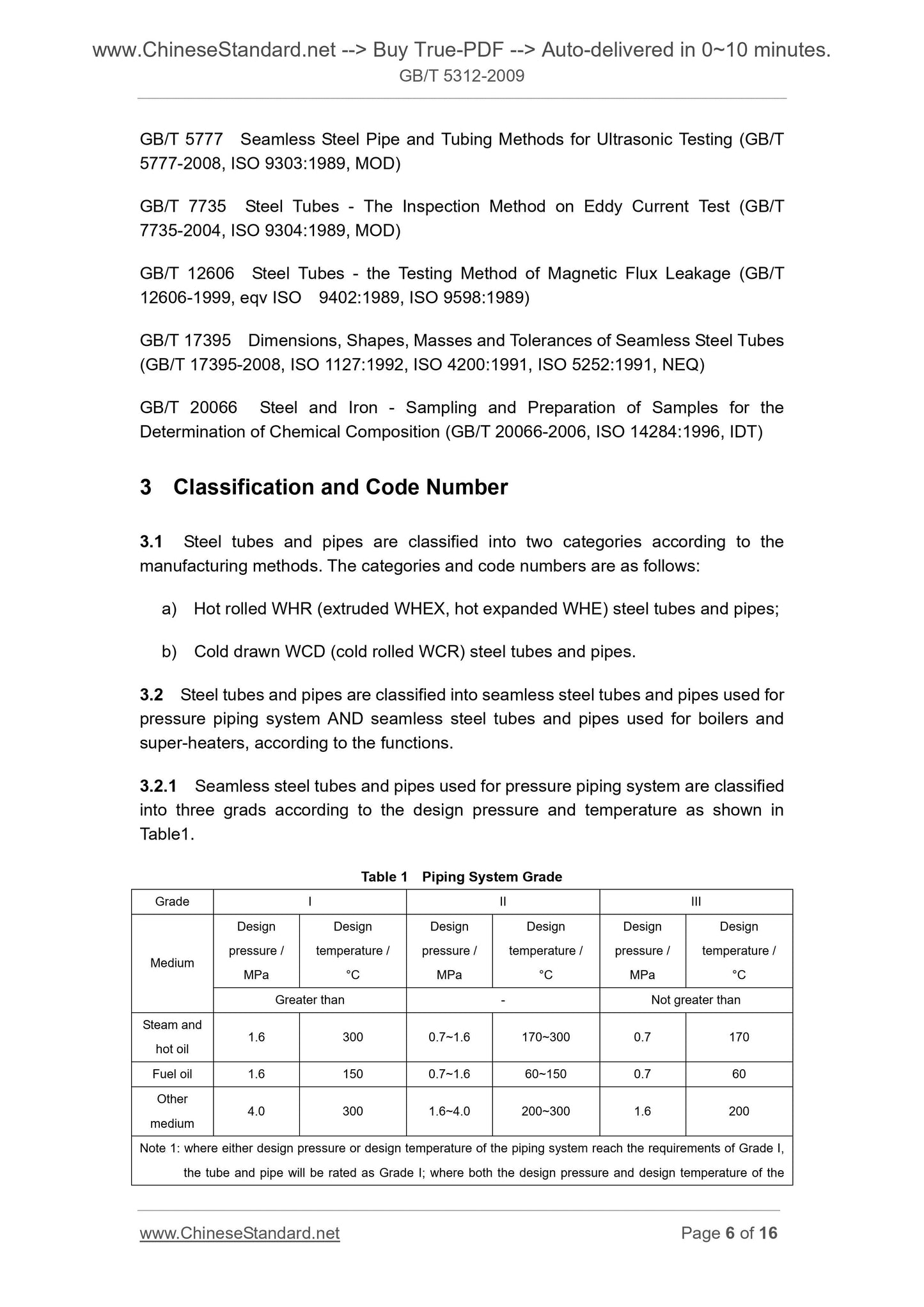

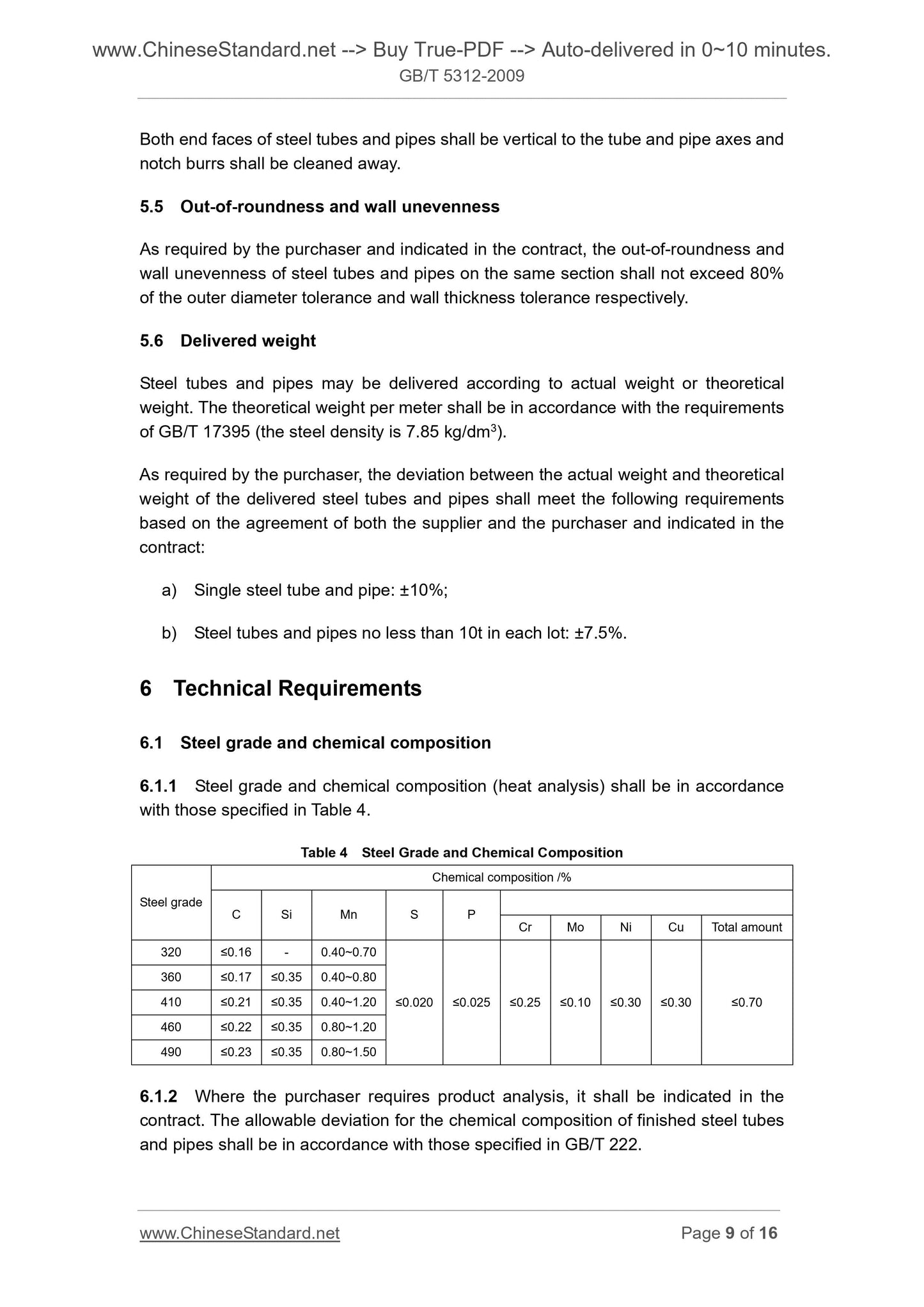

This standard specifies the classification, code number, dimension, shape, weight,technical requirements, testing method, inspection rules, packing, marking and quality

certificate of carbon and carbon-manganese steel seamless steel tubes and pipes for

ship (hereinafter referred to as steel tubes and pipes).

This standard is applicable to the carbon and carbon-manganese steel seamless

steel tubes and pipes used for Grade I and I pressure piping system, boilers and

super-heaters for manufacturing ships.

Basic Data

| Standard ID | GB/T 5312-2009 (GB/T5312-2009) |

| Description (Translated English) | Carbon and carbon-manganese steel seamless steel tubes and pipes for ship |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | H48 |

| Classification of International Standard | 77.140.75 |

| Word Count Estimation | 11,129 |

| Date of Issue | 2009-10-30 |

| Date of Implementation | 2010-05-01 |

| Older Standard (superseded by this standard) | GB/T 5312-1999 |

| Quoted Standard | GB/T 222; GB/T 223.5; GB/T 223.12; GB/T 223.26; GB/T 223.53; GB/T 223.54; GB/T 223.59; GB/T 223.63; GB/T 223.68; GB/T 223.69; GB/T 228; GB/T 229; GB/T 232; GB/T 241; GB/T 242; GB/T 245; GB/T 246; GB/T 2102; GB/T 2975; GB/T 4336; GB/T 4338; GB/T 5777; GB/T 7735; GB/T 12606; GB/T 17395; GB/T 20066 |

| Regulation (derived from) | National Standard Approval Announcement 2009 No.12 (Total No.152) |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the ship cut carbon and carbon- manganese steel seamless pipe (hereinafter referred to as the pipe) classification, Code, dimensions, Weight, , technical requirements, test methods, marking and quality certification, packaging, appearance inspection rules. This standard applies to Class I manufacture pressure vessels used in piping systems, �� grade pressure piping systems, Boiler and Superheater carbon and carbon- manganese steel seamless pipe. |

Share