1

/

of

12

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 5310-2017 English PDF (GB/T5310-2017)

GB/T 5310-2017 English PDF (GB/T5310-2017)

Regular price

$245.00

Regular price

Sale price

$245.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 5310-2017: [Including 2019XG1] Seamless steel tubes and pipes for high pressure boiler

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 5310-2017 (Self-service in 1-minute)

Newer / historical versions: GB/T 5310-2017

Preview True-PDF

Scope

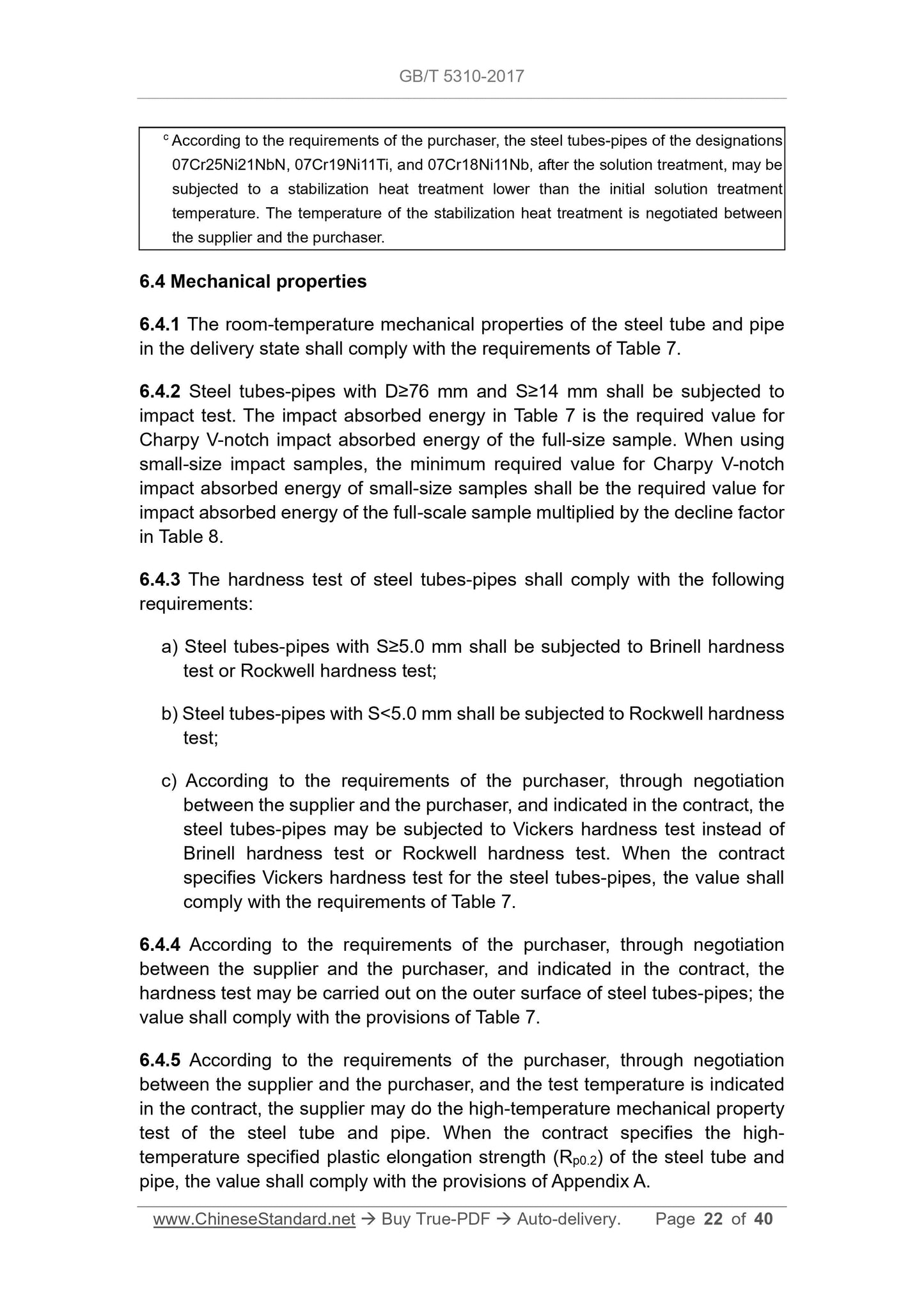

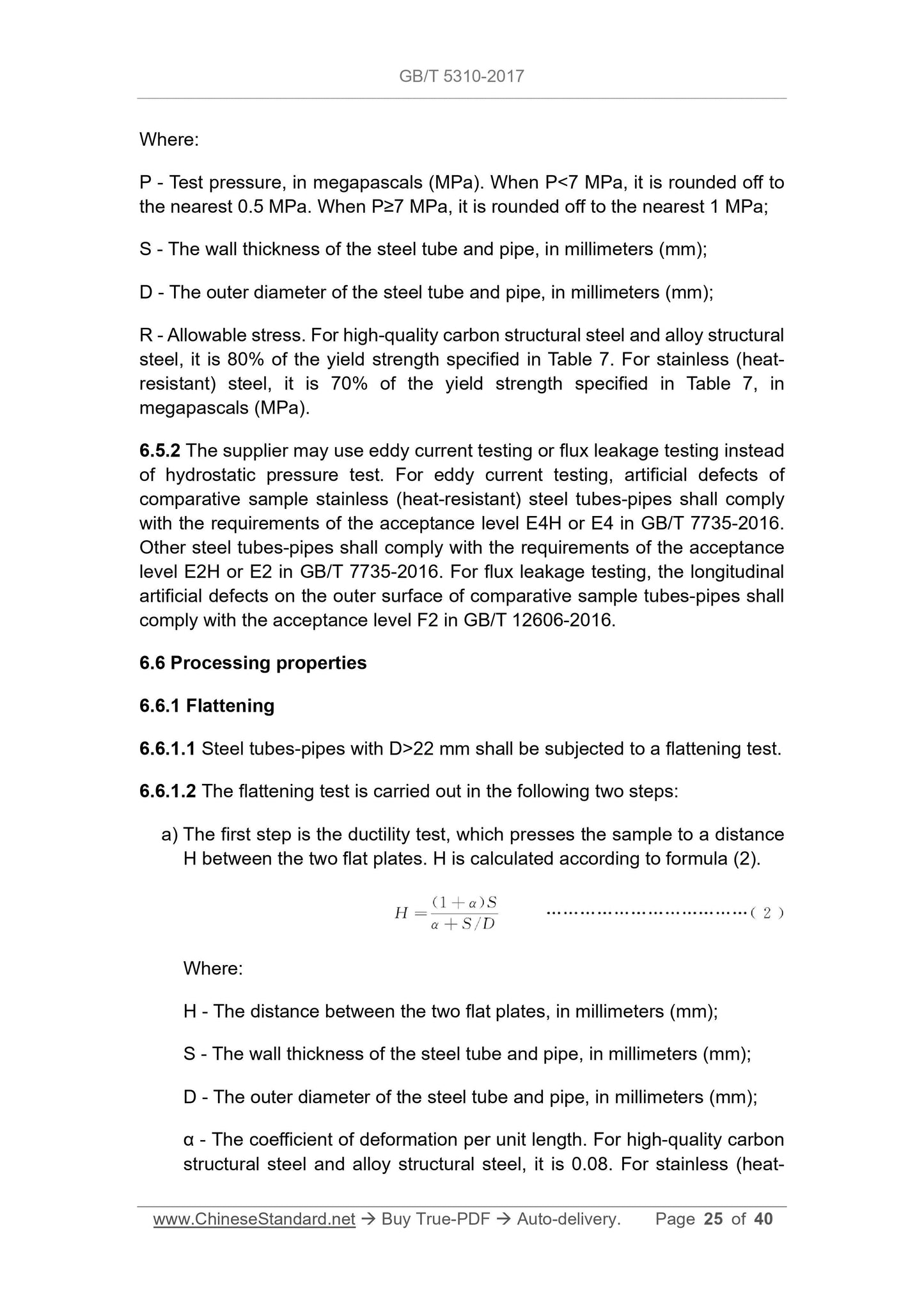

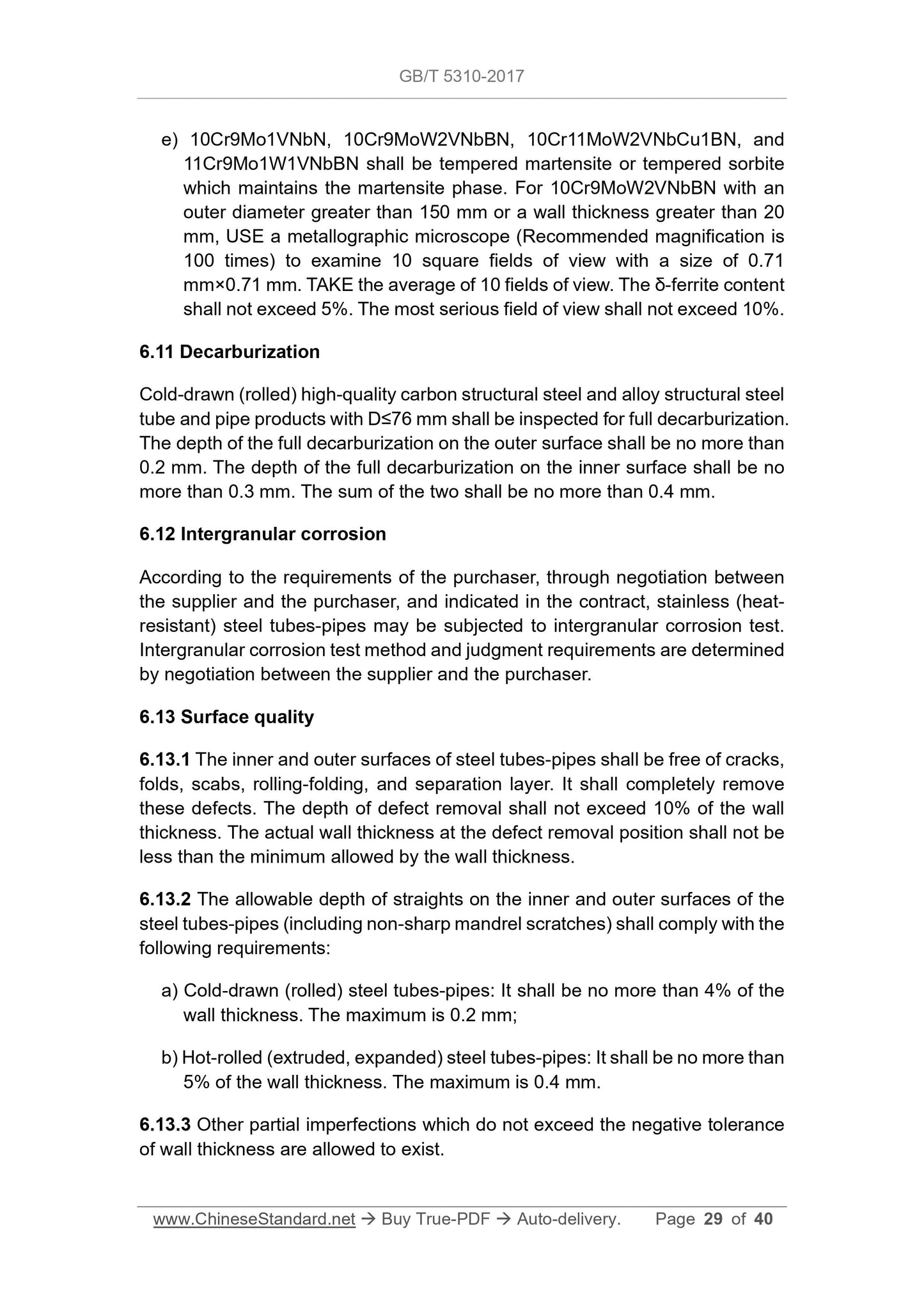

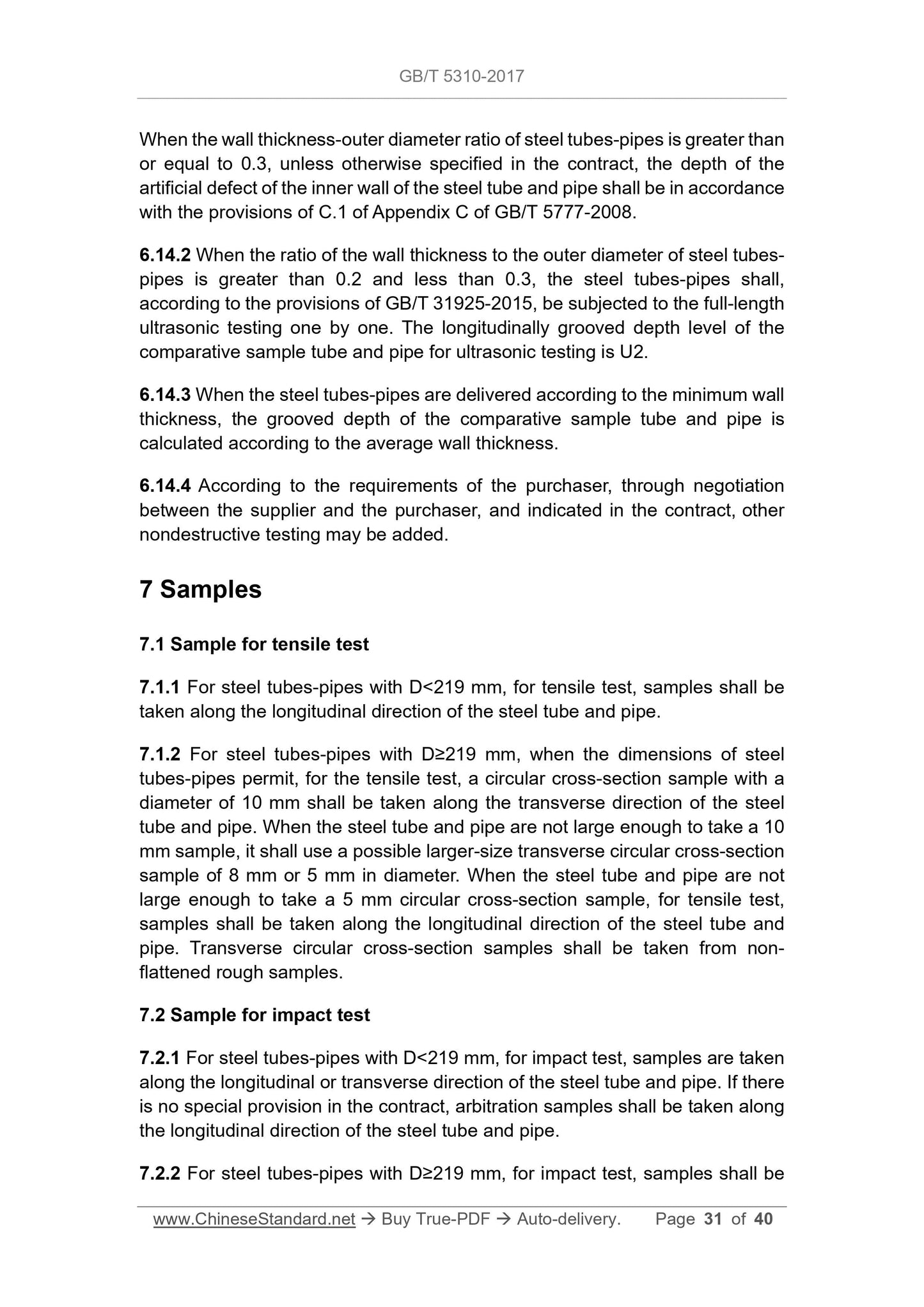

This Standard specifies the classification, code, dimensions, shapes, masses,technical requirements, samples, test methods, inspection rules, packing,

marking, and quality certification of seamless steel tubes and pipes (tubes-

pipes) for high pressure boiler.

This Standard is applicable to seamless steel tubes-pipes for the manufacture

of steam boiler and pipeline of high pressure and above.

Basic Data

| Standard ID | GB/T 5310-2017 (GB/T5310-2017) |

| Description (Translated English) | [Including 2019XG1] Seamless steel tubes and pipes for high pressure boiler |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | H48 |

| Classification of International Standard | 77.140.75 |

| Word Count Estimation | 26,266 |

| Date of Issue | 2017-12-29 |

| Date of Implementation | 2018-09-01 |

| Older Standard (superseded by this standard) | GB/T 5310-2008 |

| Regulation (derived from) | National Standards Bulletin 2017 No. 32 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

Share