1

/

of

9

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 5137.1-2020 English PDF (GB/T5137.1-2020)

GB/T 5137.1-2020 English PDF (GB/T5137.1-2020)

Regular price

$355.00

Regular price

Sale price

$355.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 5137.1-2020: Test methods of safety glazing materials used on road vehicles - Part 1: Mechanical properties tests

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 5137.1-2020 (Self-service in 1-minute)

Newer / historical versions: GB/T 5137.1-2020

Preview True-PDF

Scope

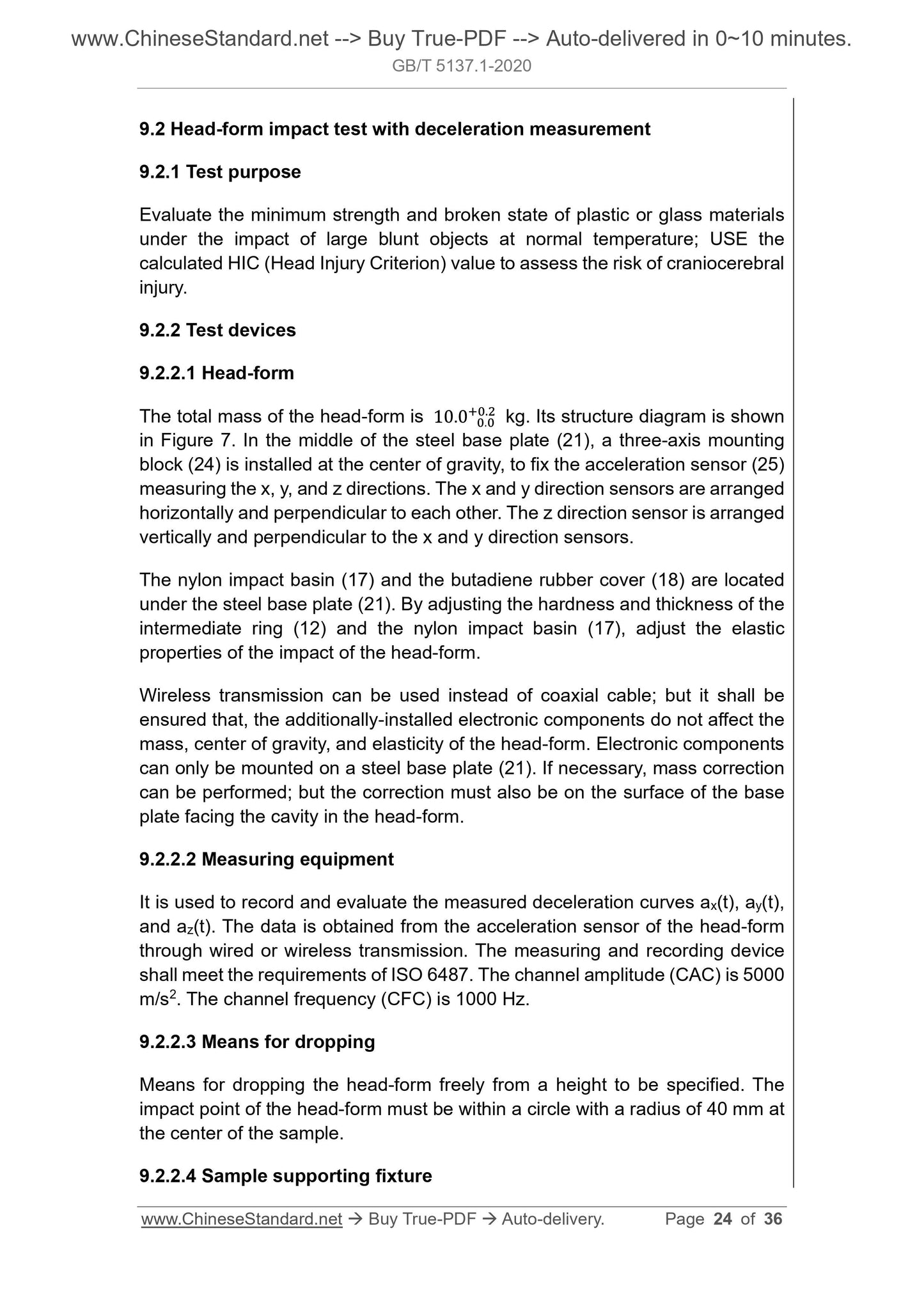

This Part of GB/T 5137 specifies the test methods for impact resistance test,penetration resistance test, abrasion resistance test, fragmentation test, head-

form impact test, cross-cut test, and flexibility and folding test of safety glazing

materials used on road vehicles.

Basic Data

| Standard ID | GB/T 5137.1-2020 (GB/T5137.1-2020) |

| Description (Translated English) | Test methods of safety glazing materials used on road vehicles - Part 1: Mechanical properties tests |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | T34 |

| Classification of International Standard | 43.040.60 |

| Word Count Estimation | 26,251 |

| Date of Issue | 2020-03-31 |

| Date of Implementation | 2021-02-01 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share