1

/

of

9

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 5009.37-2003 English PDF (GB/T5009.37-2003)

GB/T 5009.37-2003 English PDF (GB/T5009.37-2003)

Regular price

$105.00

Regular price

Sale price

$105.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

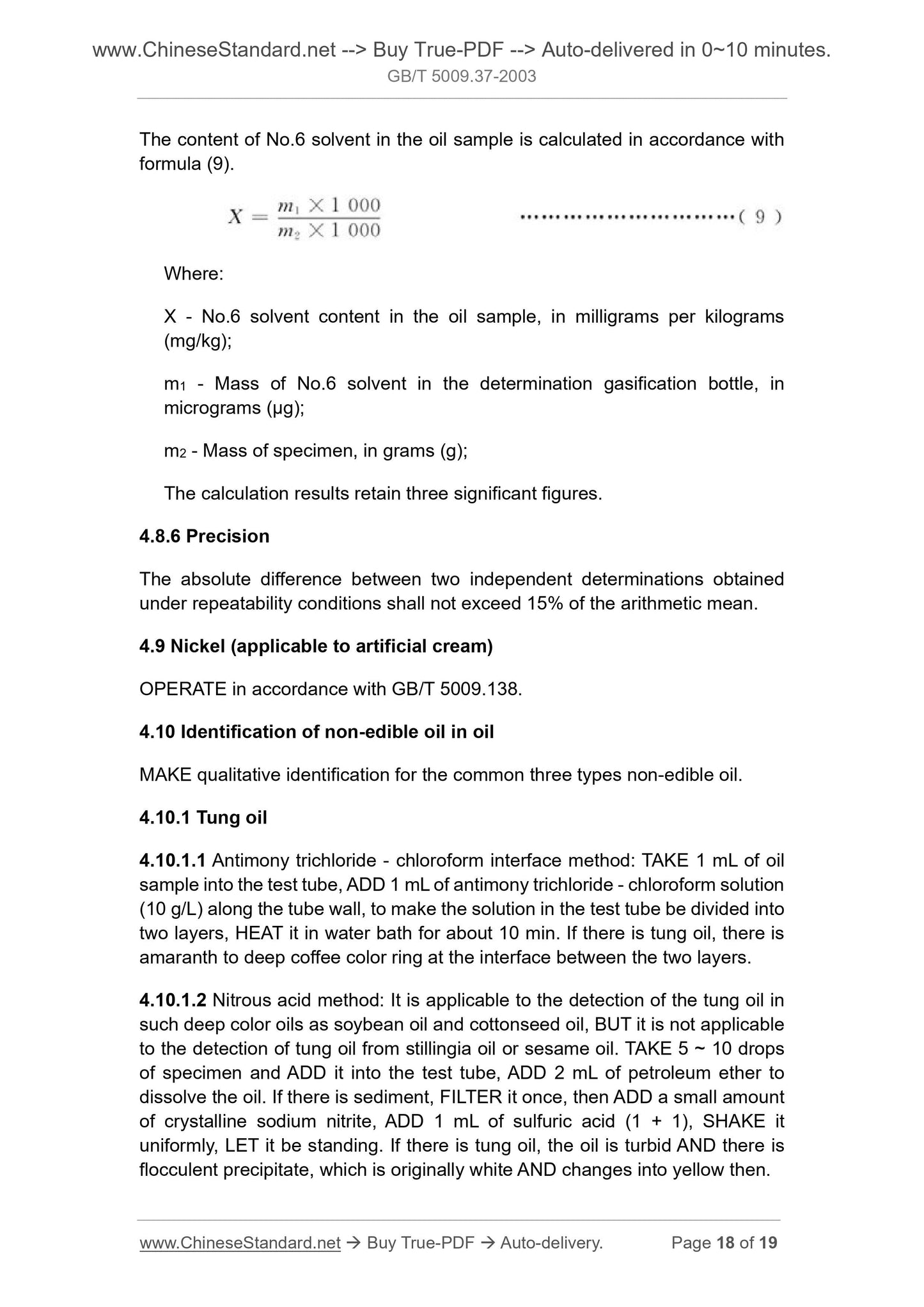

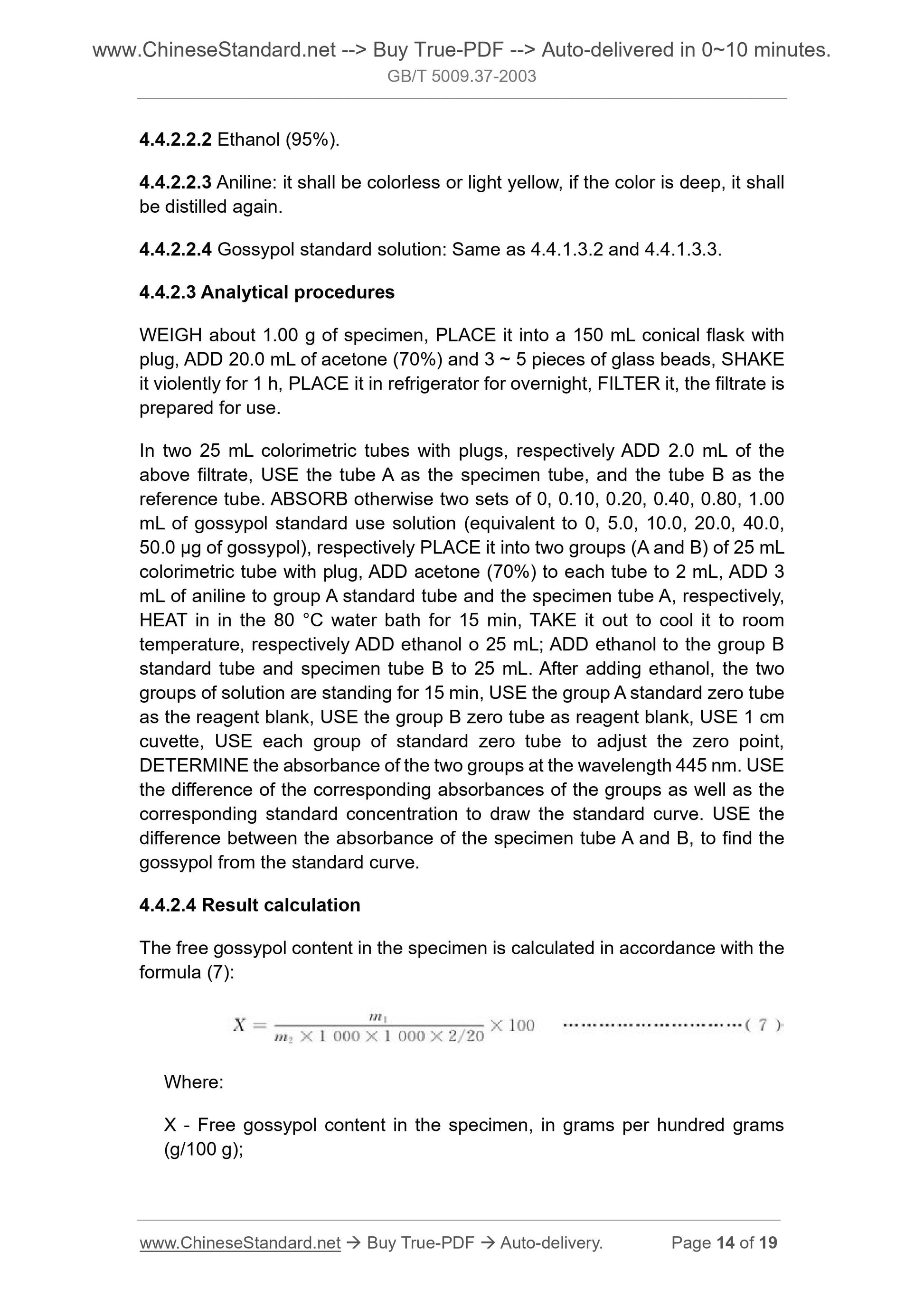

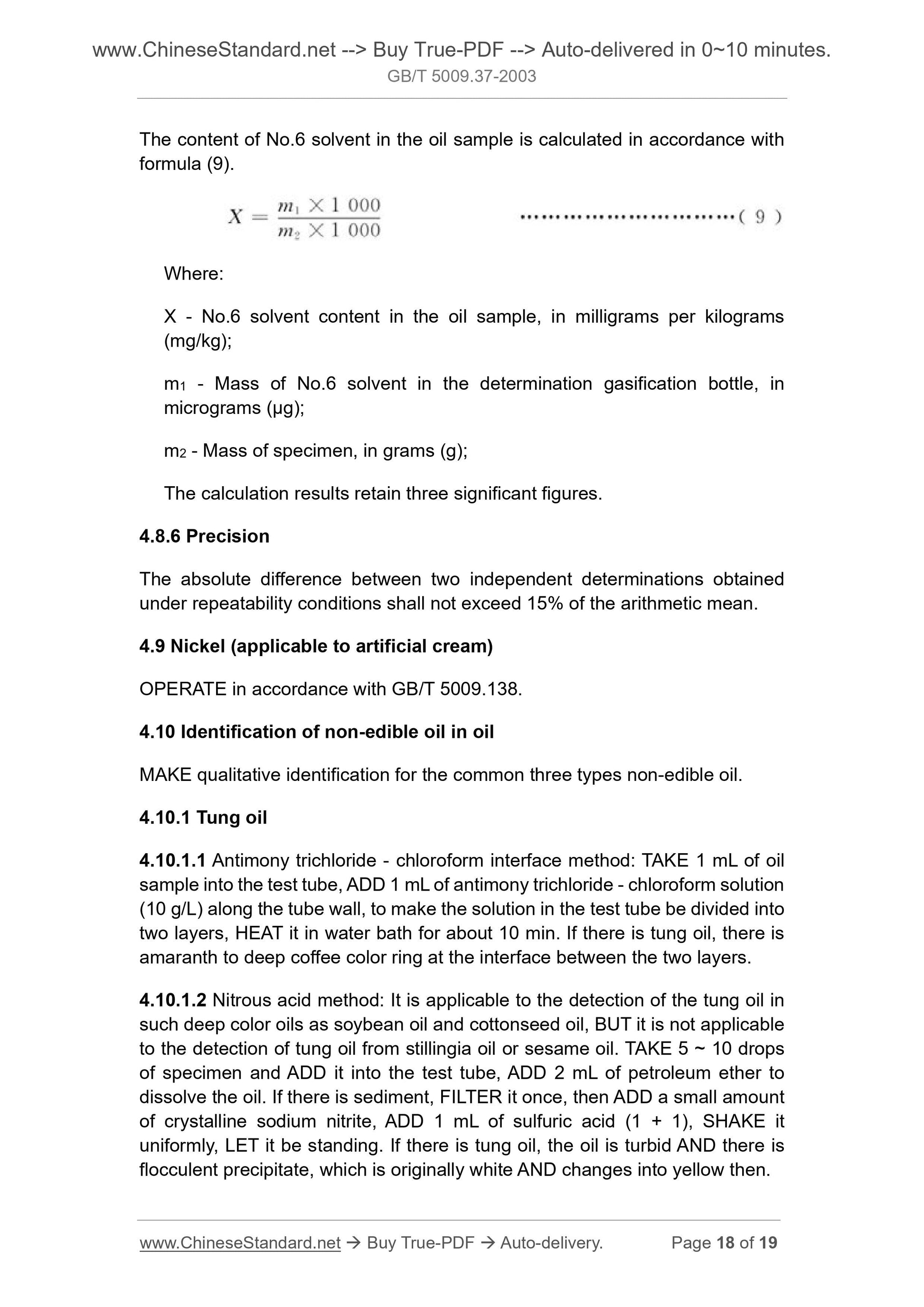

GB/T 5009.37-2003: Method for analysis of hygienic standard of edible oils

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 5009.37-2003 (Self-service in 1-minute)

Newer / historical versions: GB/T 5009.37-2003

Preview True-PDF

Scope

This standard specifies the analysis method for edible vegetable oil hygieneindicators.

This standard applies to the analysis of edible vegetable oil hygiene indicators.

The detection limit of the residual solvent in this method is 0.10 mg/kg, the

detection limit of the second method of peroxide value is 0.003 meq/kg.

Basic Data

| Standard ID | GB/T 5009.37-2003 (GB/T5009.37-2003) |

| Description (Translated English) | Method for analysis of hygienic standard of edible oils |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | C53 |

| Classification of International Standard | 67.040 |

| Word Count Estimation | 10,197 |

| Date of Issue | 2003-08-11 |

| Date of Implementation | 2004-01-01 |

| Older Standard (superseded by this standard) | GB/T 5009.37-1996 |

| Quoted Standard | GB/T 5009.11; GB/T 5009.22; GB/T 5009.27; GB/T 5009.138 |

| Issuing agency(ies) | The People Republic of China Ministry of Health, China National Standardization Management Committee |

| Summary | This standard specifies: edible vegetable oil health indicators analysis. This standard applies to: edible vegetable oil health indicators analysis. The method of residual solvents a detection limit of 0. 10mg/kg, peroxide value of the second law the detection limit of 0. 003meq/kg. |

Share