1

/

of

7

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 5009.18-2003 English PDF (GB/T5009.18-2003)

GB/T 5009.18-2003 English PDF (GB/T5009.18-2003)

Regular price

$70.00

Regular price

Sale price

$70.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 5009.18-2003: Determination of fluorine in foods

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 5009.18-2003 (Self-service in 1-minute)

Newer / historical versions: GB/T 5009.18-2003

Preview True-PDF

Scope

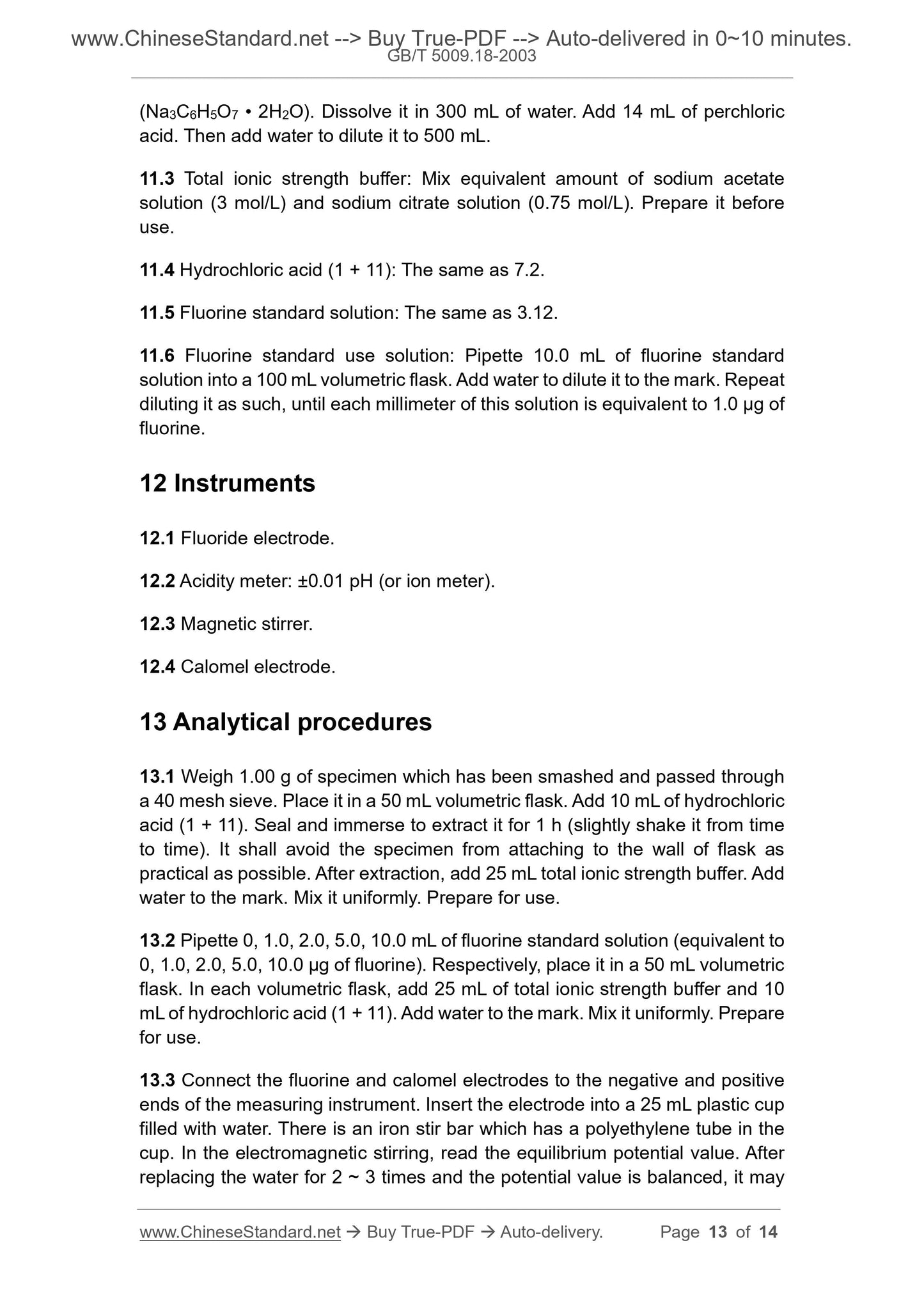

This standard specifies the method for determination of fluorine in foods suchas grains, vegetables, fruits, beans and their products, meat, fish, eggs.

This standard applies to the determination of fluorine in foods. The fluoride ion

selective electrode method is not suitable for the specimens which have higher

fat content but are not ashed (such as peanuts, fat meat, etc.).

The detection limit of this method is 0.10 mg/kg for the method 1 and 1.25 mg/kg

for the method 2.

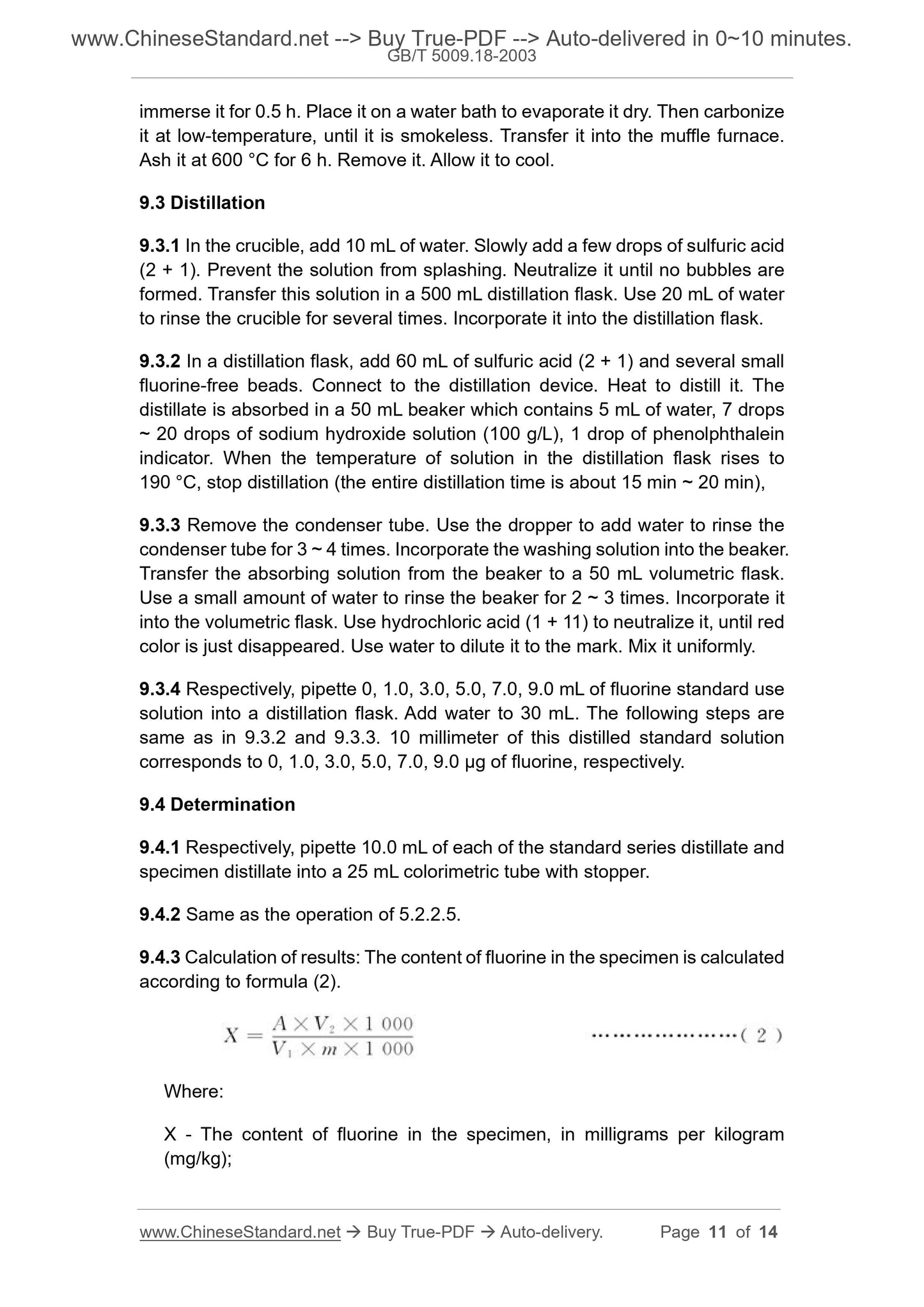

Method 1 -- Diffusion-fluorine reagent colorimetry

Basic Data

| Standard ID | GB/T 5009.18-2003 (GB/T5009.18-2003) |

| Description (Translated English) | Determination of fluorine in foods |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | C53 |

| Classification of International Standard | 67.040 |

| Word Count Estimation | 8,845 |

| Date of Issue | 2003-08-11 |

| Date of Implementation | 2004-01-01 |

| Older Standard (superseded by this standard) | GB/T 5009.18-1996 |

| Summary | This standard specifies: grain, vegetables, fruits, legumes and their products, meat, fish, eggs and other foods fluorine determination. This standard applies to: foods fluorine determination. Fluoride ion selective electrode method does not apply to high fat content but without the ash sample (eg |

Share