1

/

of

9

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 4802.2-2008 English PDF (GB/T4802.2-2008)

GB/T 4802.2-2008 English PDF (GB/T4802.2-2008)

Regular price

$85.00

Regular price

Sale price

$85.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

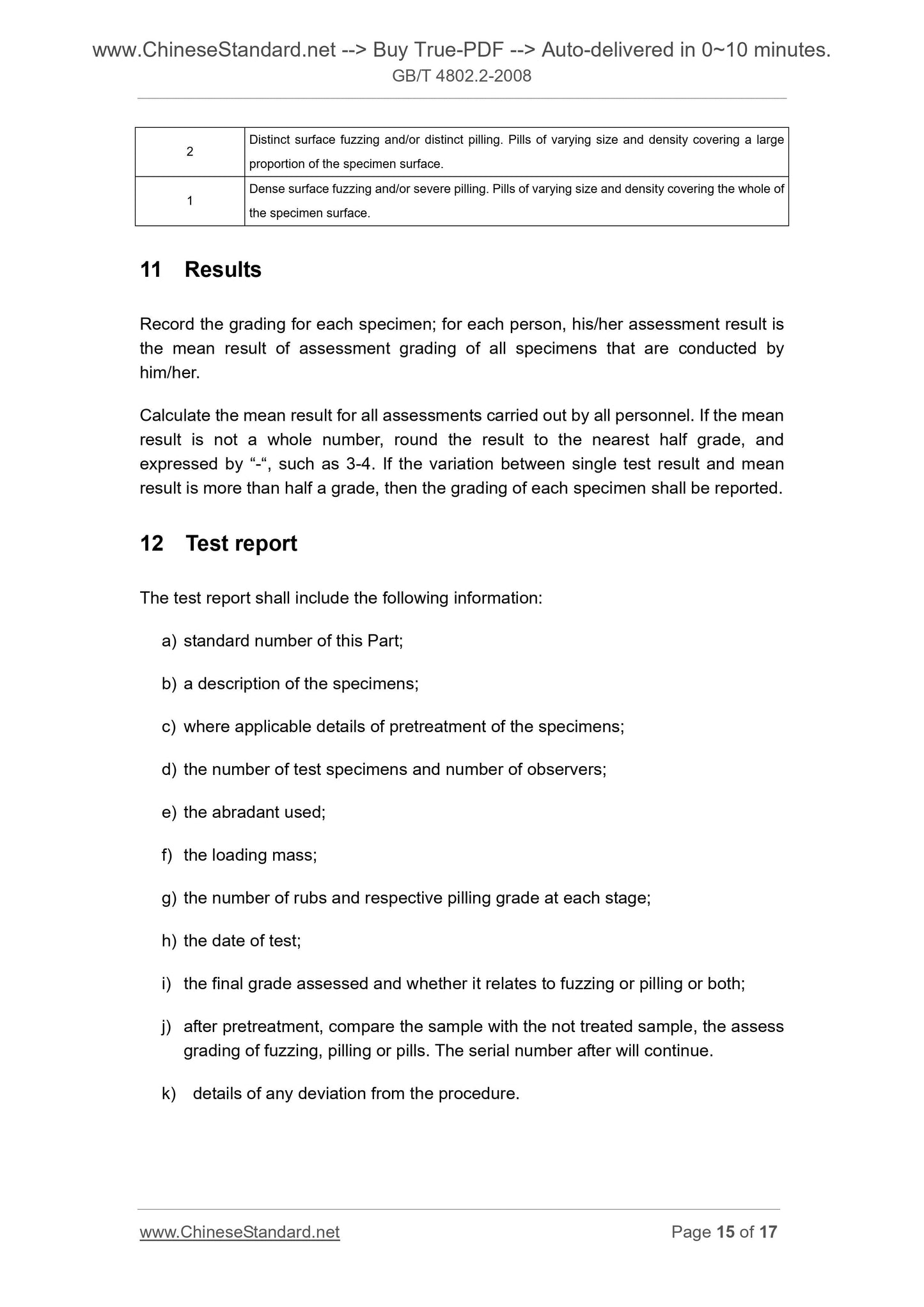

GB/T 4802.2-2008: Textiles -- Determination of fabric propensity to surface fuzzing and to pilling -- Part 2: Modified Martindale method

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 4802.2-2008 (Self-service in 1-minute)

Newer / historical versions: GB/T 4802.2-2008

Preview True-PDF

Scope

This Part of GB/T 4802 specifies a method for determination of the resistance topilling and surface change of textile fabrics using a modified Martindale method.

Basic Data

| Standard ID | GB/T 4802.2-2008 (GB/T4802.2-2008) |

| Description (Translated English) | Textiles -- Determination of fabric propensity to surface fuzzing and to pilling -- Part 2: Modified Martindale method |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | W04 |

| Classification of International Standard | 59.080.30 |

| Word Count Estimation | 12,123 |

| Date of Issue | 2008-06-18 |

| Date of Implementation | 2009-03-01 |

| Older Standard (superseded by this standard) | GB/T 4802.2-1997 |

| Quoted Standard | GB/T 6529; GB/T 21196.1 |

| Adopted Standard | ISO 12945-2-2000, MOD |

| Regulation (derived from) | National Standard Approval Announcement 2008 No.10 (Total No.123) |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the determination method using modified Martindale pilling properties and surface change. |

Share