1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB/T 4502-2016 English PDF (GB/T4502-2016)

GB/T 4502-2016 English PDF (GB/T4502-2016)

Regular price

$125.00

Regular price

Sale price

$125.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 4502-2016: Laboratory test methods for passenger car tyres capabilities

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 4502-2016 (Self-service in 1-minute)

Newer / historical versions: GB/T 4502-2016

Preview True-PDF

Scope

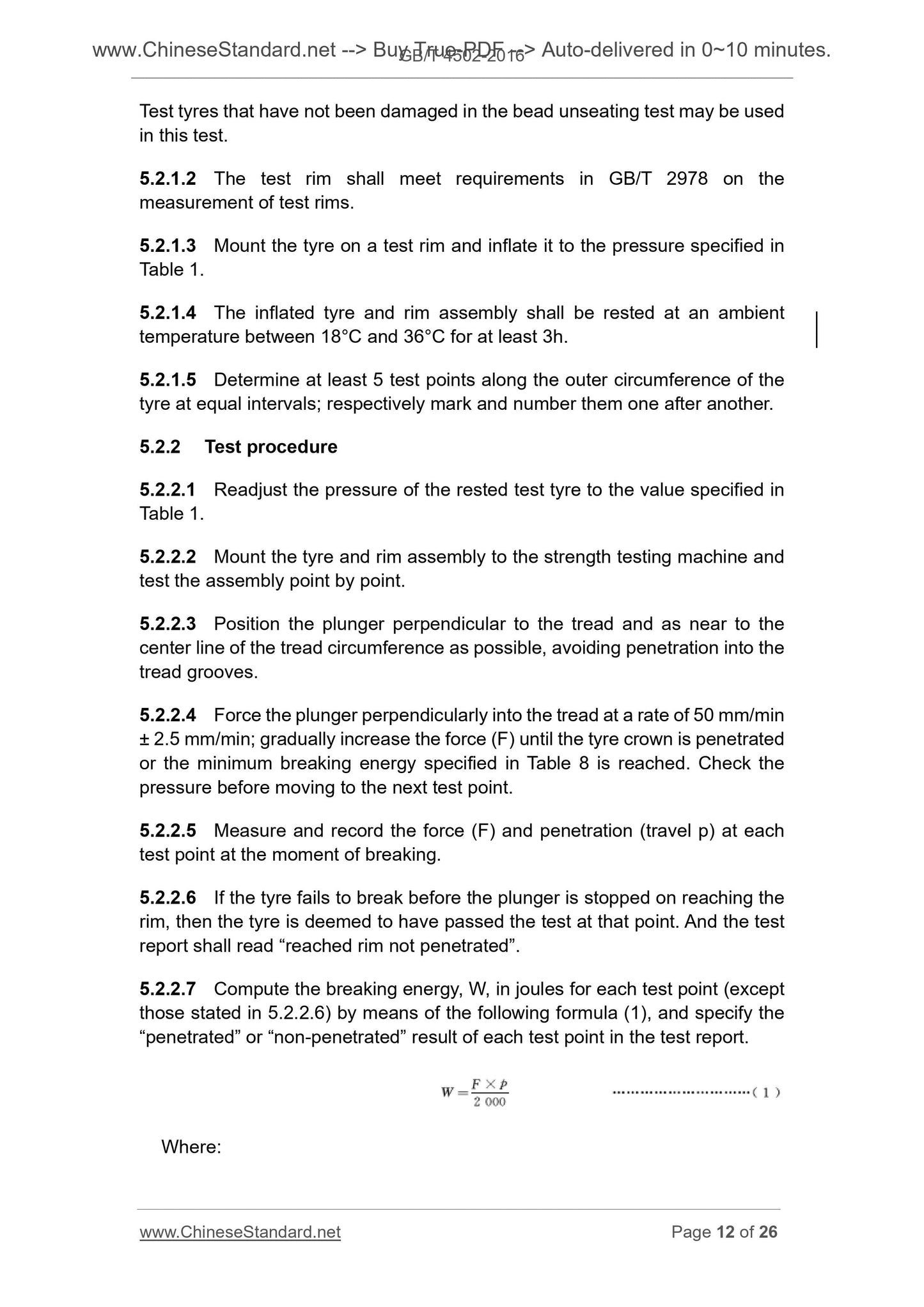

This Standard specifies laboratory test methods for verifying the capabilities oftyres for passenger cars, including terms and definitions used in the tests,

testing equipment and precision, test conditions, testing procedures, judgment

criteria, and test reports. Of the test methods presented, it is possible that only

some will be required, depending on the type of tyre to be tested (tube or

tubeless, diagonal or radial).

This Standard includes.

(1) Bead unseating test. assesses the resistance of the tubeless tyre to bead

unseating.

(2) Strength test. assesses the capability of the tyre structure, with respect

to braking energy, in the tread area.

(3) High speed test. assesses the capability of the tyre according to its

speed category.

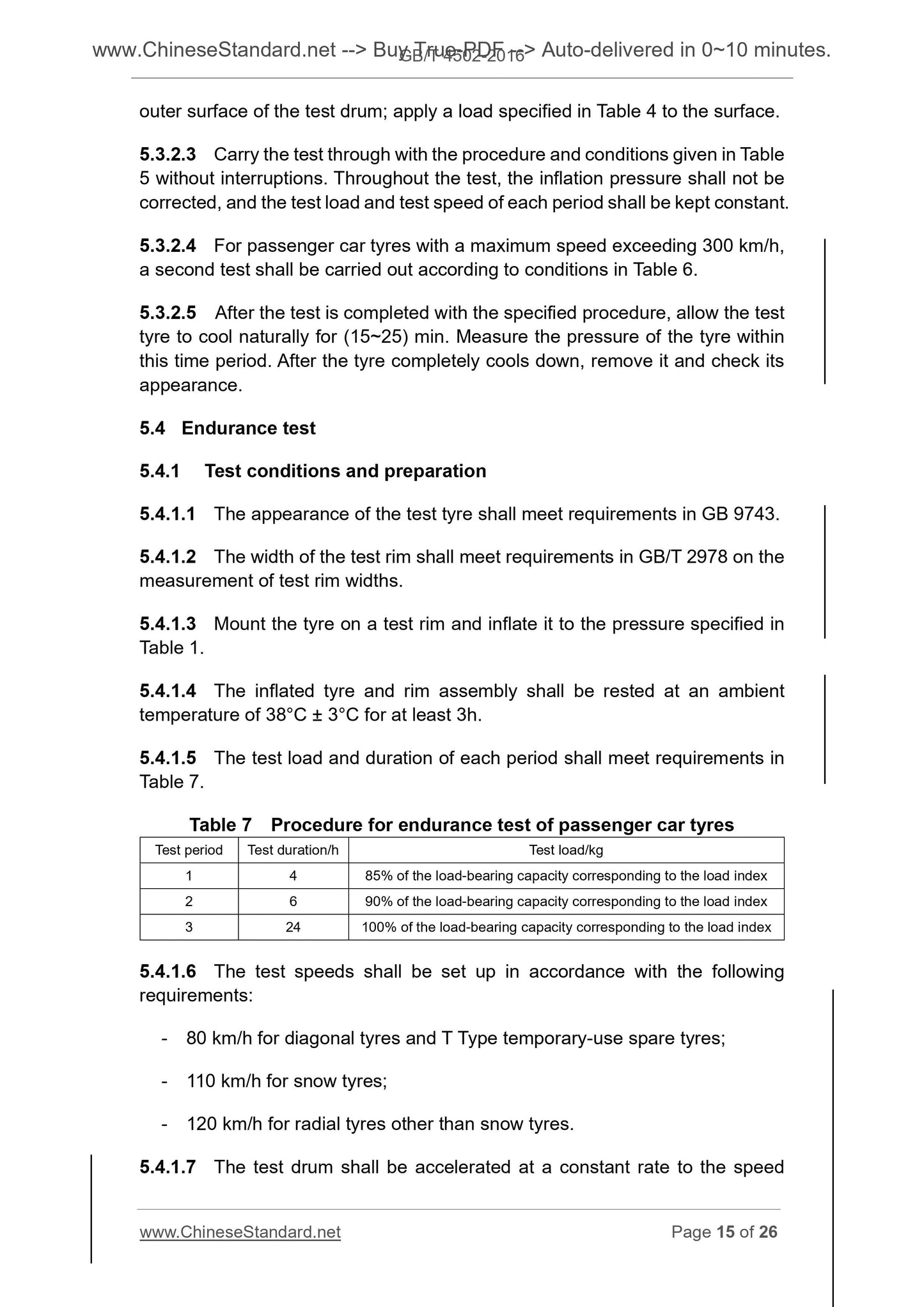

(4) Endurance test. assesses the resistance of the type, with respect to

service at specified load and speed.

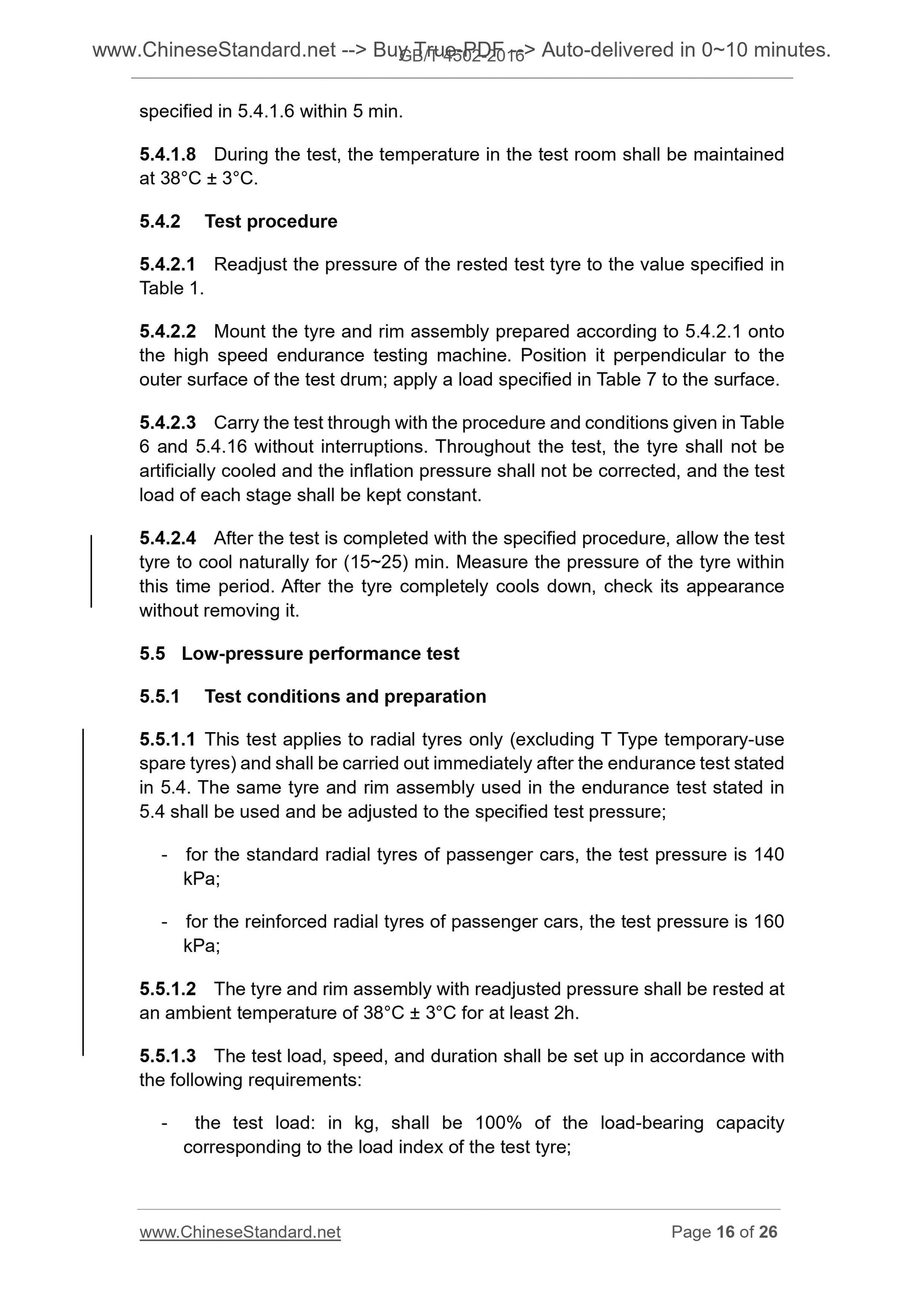

(5) Low-pressure performance test. assesses reliability of radial tyres under

low pressure, with respect to service at specified load, speed, and low

pressure conditions.

The test methods presented in this Standard are not intended for gradation of

tyre performance or quality levels.

This Standard applies to all pneumatic-tyres for passenger cars.

Basic Data

| Standard ID | GB/T 4502-2016 (GB/T4502-2016) |

| Description (Translated English) | Laboratory test methods for passenger car tyres capabilities |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | G41 |

| Classification of International Standard | 83.160.10 |

| Word Count Estimation | 18,157 |

| Date of Issue | 1984-06-17 |

| Date of Implementation | 2017-07-01 |

| Regulation (derived from) | National Standard Notice No. 14 of 2016 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

Share