1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 44257.1-2024 English PDF (GB/T44257.1-2024)

GB/T 44257.1-2024 English PDF (GB/T44257.1-2024)

Regular price

$575.00

Regular price

Sale price

$575.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

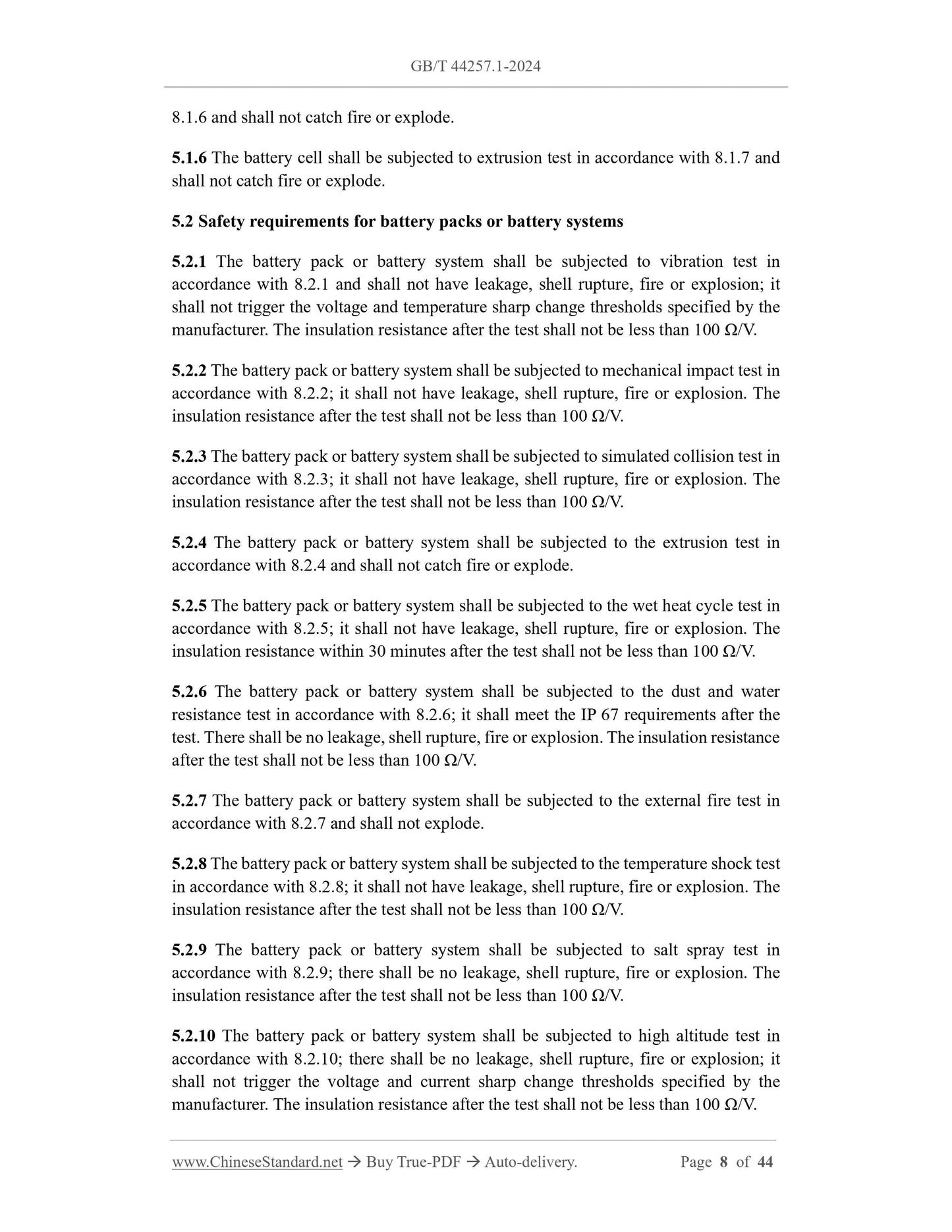

GB/T 44257.1-2024: Traction battery of electric earth-moving machinery - Part 1: Safety requirements

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 44257.1-2024 (Self-service in 1-minute)

Newer / historical versions: GB/T 44257.1-2024

Preview True-PDF

Scope

This document specifies the safety requirements for power battery cells, battery packsor battery systems for electric earthmoving machinery; describes the relevant test

methods.

This document is applicable to the manufacture of power lithium-ion batteries for

electric earthmoving machinery; the manufacture of other types of power batteries is

implemented with reference to it.

Basic Data

| Standard ID | GB/T 44257.1-2024 (GB/T44257.1-2024) |

| Description (Translated English) | Traction battery of electric earth-moving machinery - Part 1: Safety requirements |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | P97 |

| Classification of International Standard | 53.100 |

| Word Count Estimation | 34,365 |

| Date of Issue | 2024-07-24 |

| Date of Implementation | 2024-07-24 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share