1

/

of

7

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 44176-2024 English PDF (GB/T44176-2024)

GB/T 44176-2024 English PDF (GB/T44176-2024)

Regular price

$350.00

Regular price

Sale price

$350.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

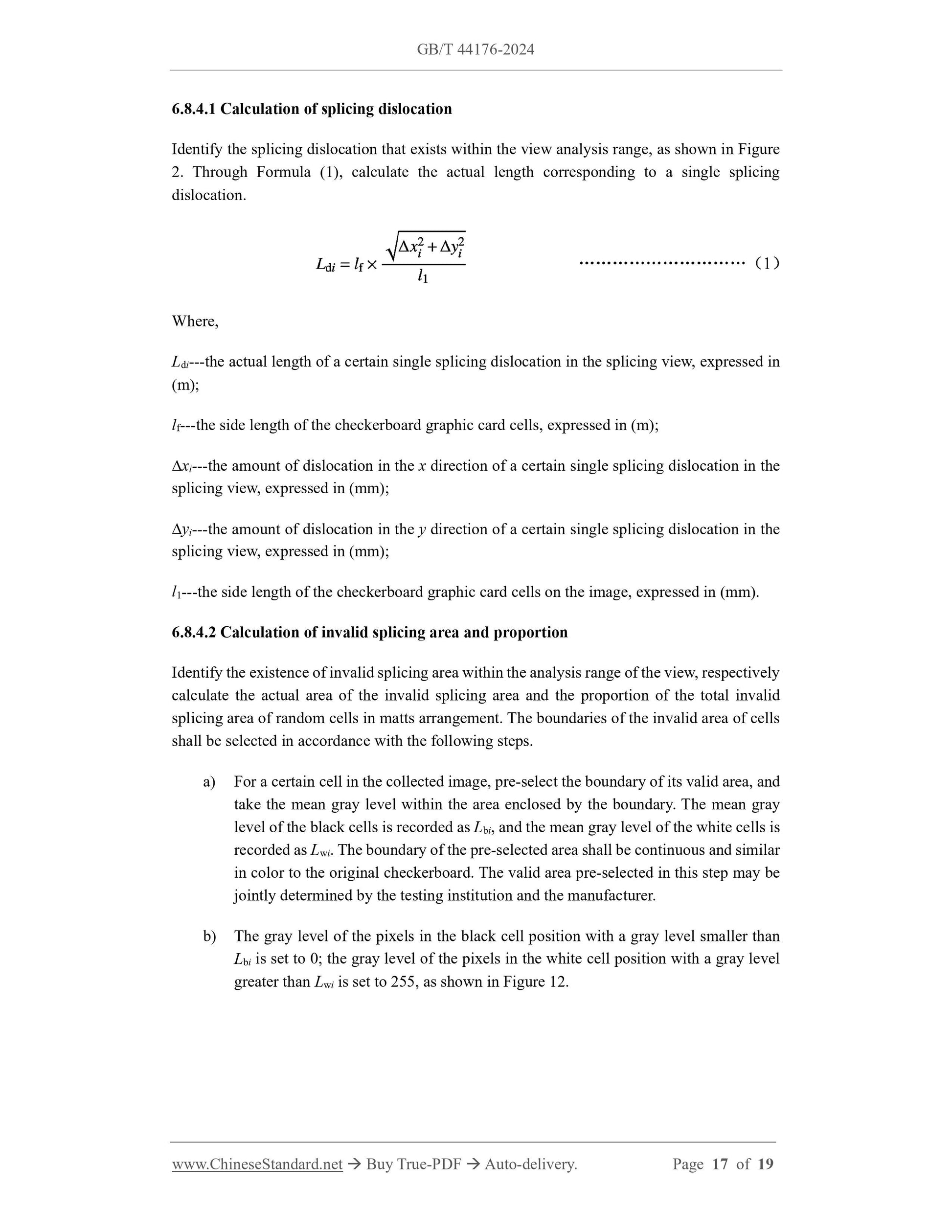

GB/T 44176-2024: Performance requirements and testing methods for around view monitoring system of vehicles

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 44176-2024 (Self-service in 1-minute)

Newer / historical versions: GB/T 44176-2024

Preview True-PDF

Scope

This document specifies the general requirements and performance requirements for aroundview monitoring system when the vehicle is stationary and driving at a low speed and describes

the test methods.

This document is applicable to Category-M and Category-N non-articulated vehicles equipped

with the around view monitoring system. Other types of vehicles may take this as a reference.

Basic Data

| Standard ID | GB/T 44176-2024 (GB/T44176-2024) |

| Description (Translated English) | Performance requirements and testing methods for around view monitoring system of vehicles |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | T40 |

| Classification of International Standard | 43.020 |

| Word Count Estimation | 18,140 |

| Date of Issue | 2024-07-24 |

| Date of Implementation | 2024-07-24 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share