1

/

of

10

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 43092-2023 English PDF (GB/T43092-2023)

GB/T 43092-2023 English PDF (GB/T43092-2023)

Regular price

$325.00

Regular price

Sale price

$325.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 43092-2023: Electrochemical performance test of lithium ion battery cathode materials - Test method for high temperature performance

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 43092-2023 (Self-service in 1-minute)

Newer / historical versions: GB/T 43092-2023

Preview True-PDF

Scope

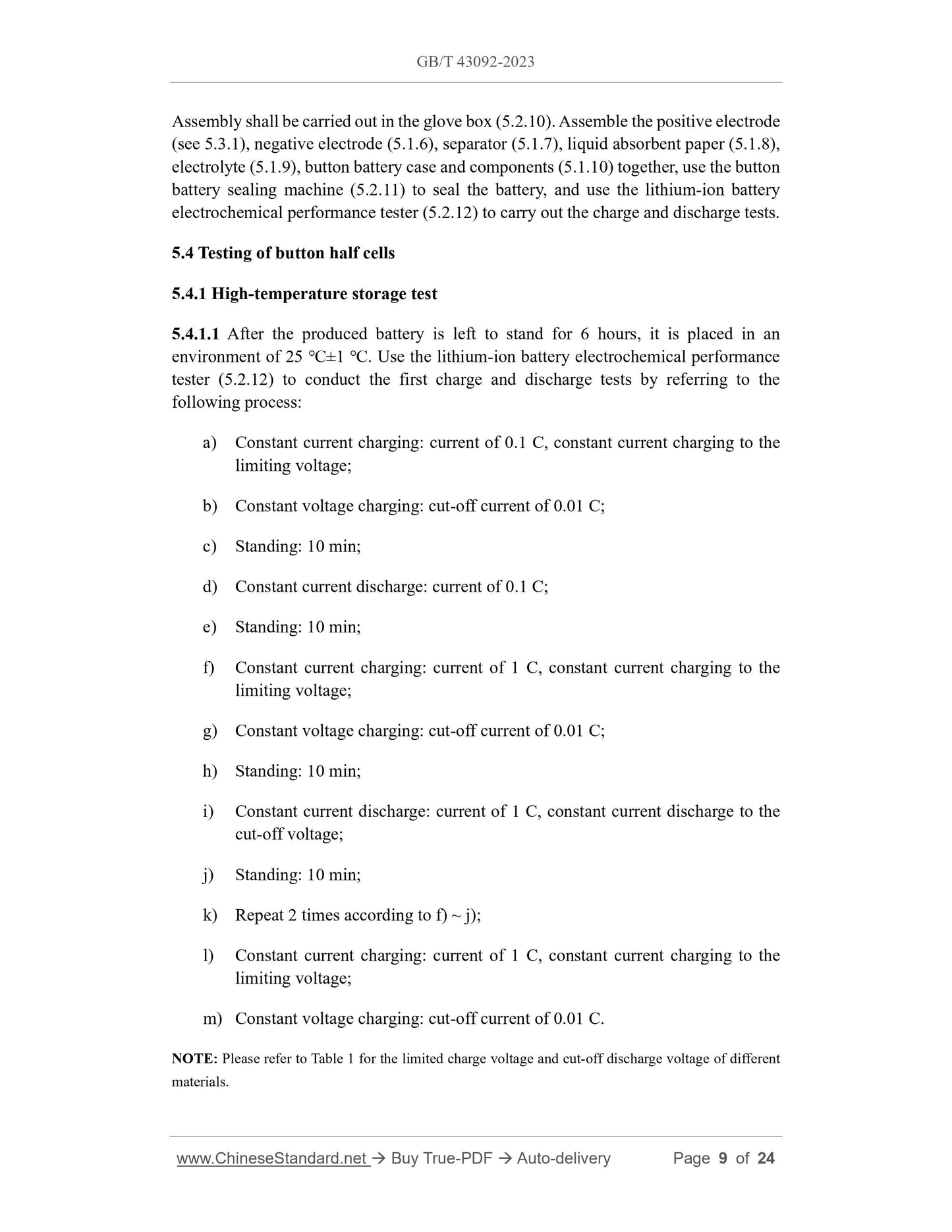

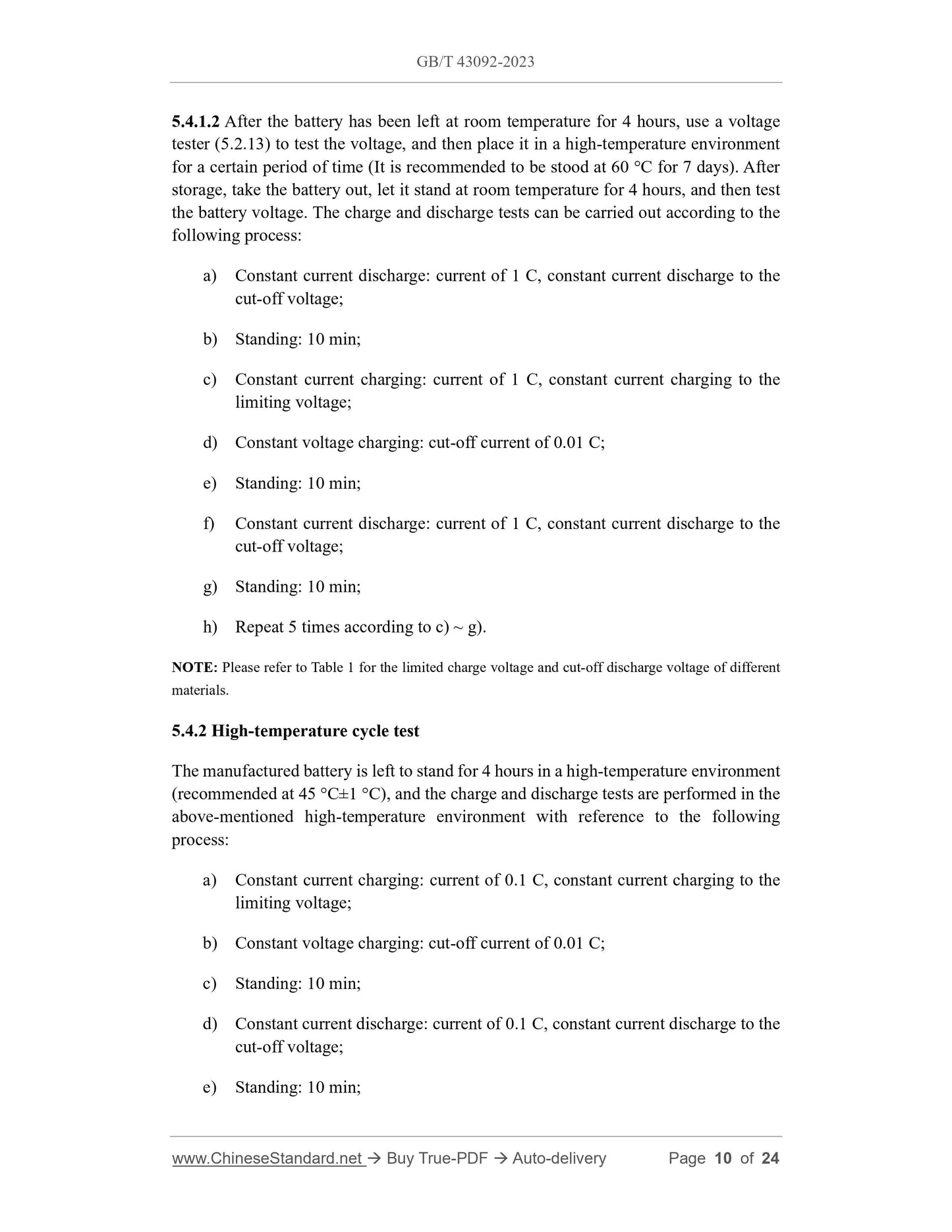

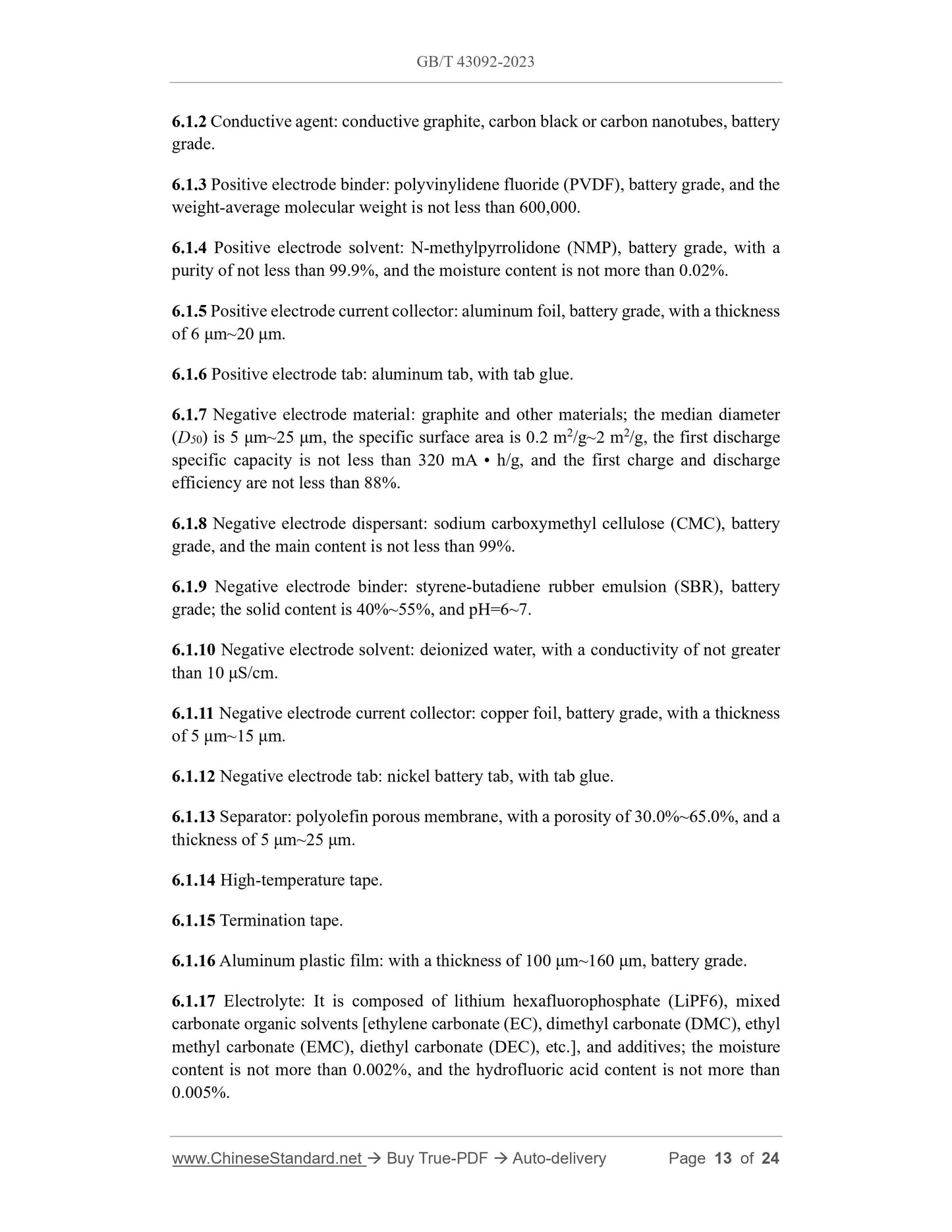

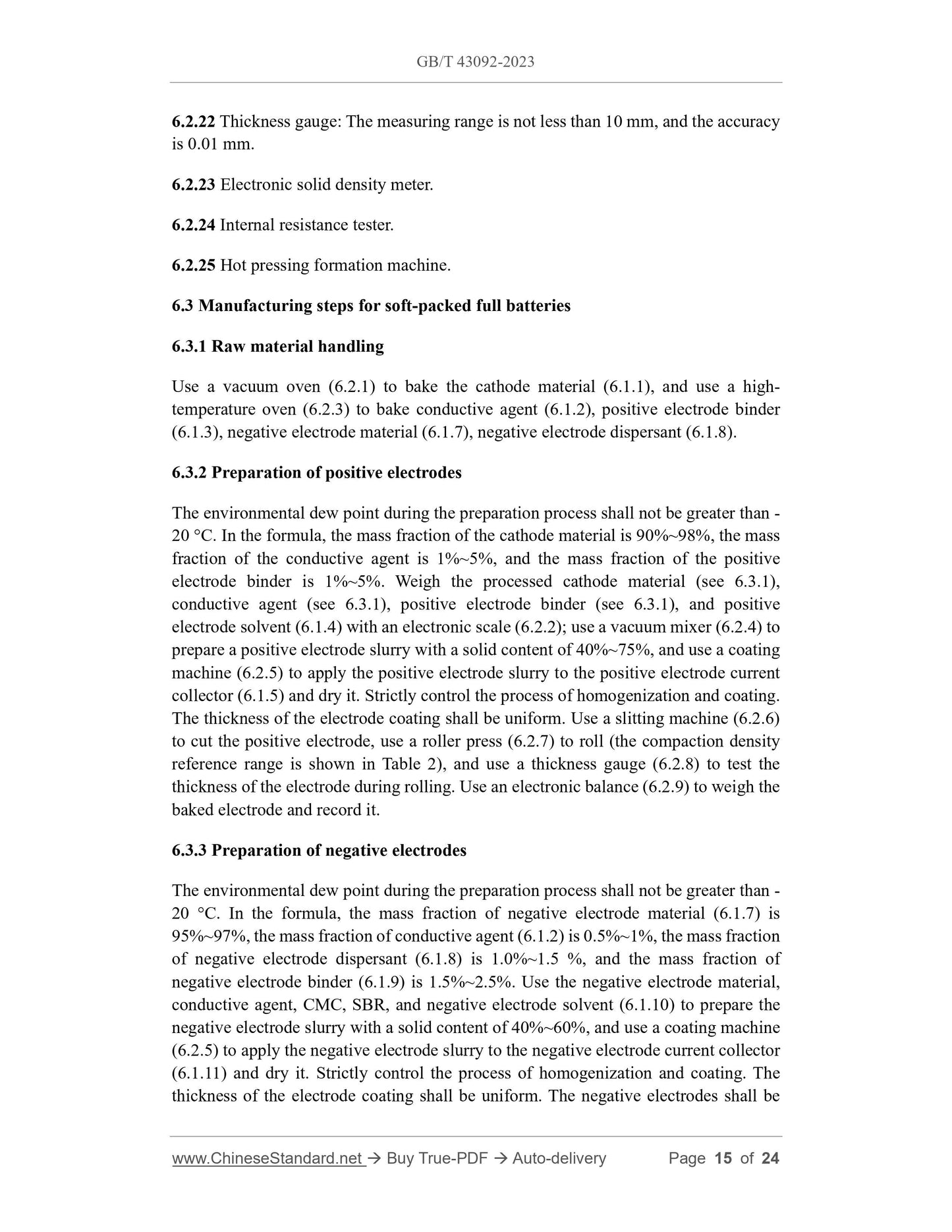

This document specifies test methods for the high-temperature electrochemicalperformance of lithium-ion battery cathode materials, including high-temperature

storage testing and high-temperature cycle testing.

This document is suitable for high-temperature electrochemical performance testing of

cathode materials such as lithium cobalt oxide, lithium nickel cobalt manganate, lithium

nickel cobalt aluminate, lithium manganate, lithium iron phosphate, and lithium-rich

manganese base for lithium-ion batteries.

Basic Data

| Standard ID | GB/T 43092-2023 (GB/T43092-2023) |

| Description (Translated English) | Electrochemical performance test of lithium ion battery cathode materials - Test method for high temperature performance |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | H21 |

| Classification of International Standard | 77.160 |

| Word Count Estimation | 18,115 |

| Date of Issue | 2023-09-07 |

| Date of Implementation | 2024-04-01 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share