1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 41875-2022 English PDF (GB/T41875-2022)

GB/T 41875-2022 English PDF (GB/T41875-2022)

Regular price

$170.00

Regular price

Sale price

$170.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 41875-2022: Seamless thin-wall molybdenum tubes

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 41875-2022 (Self-service in 1-minute)

Newer / historical versions: GB/T 41875-2022

Preview True-PDF

Scope

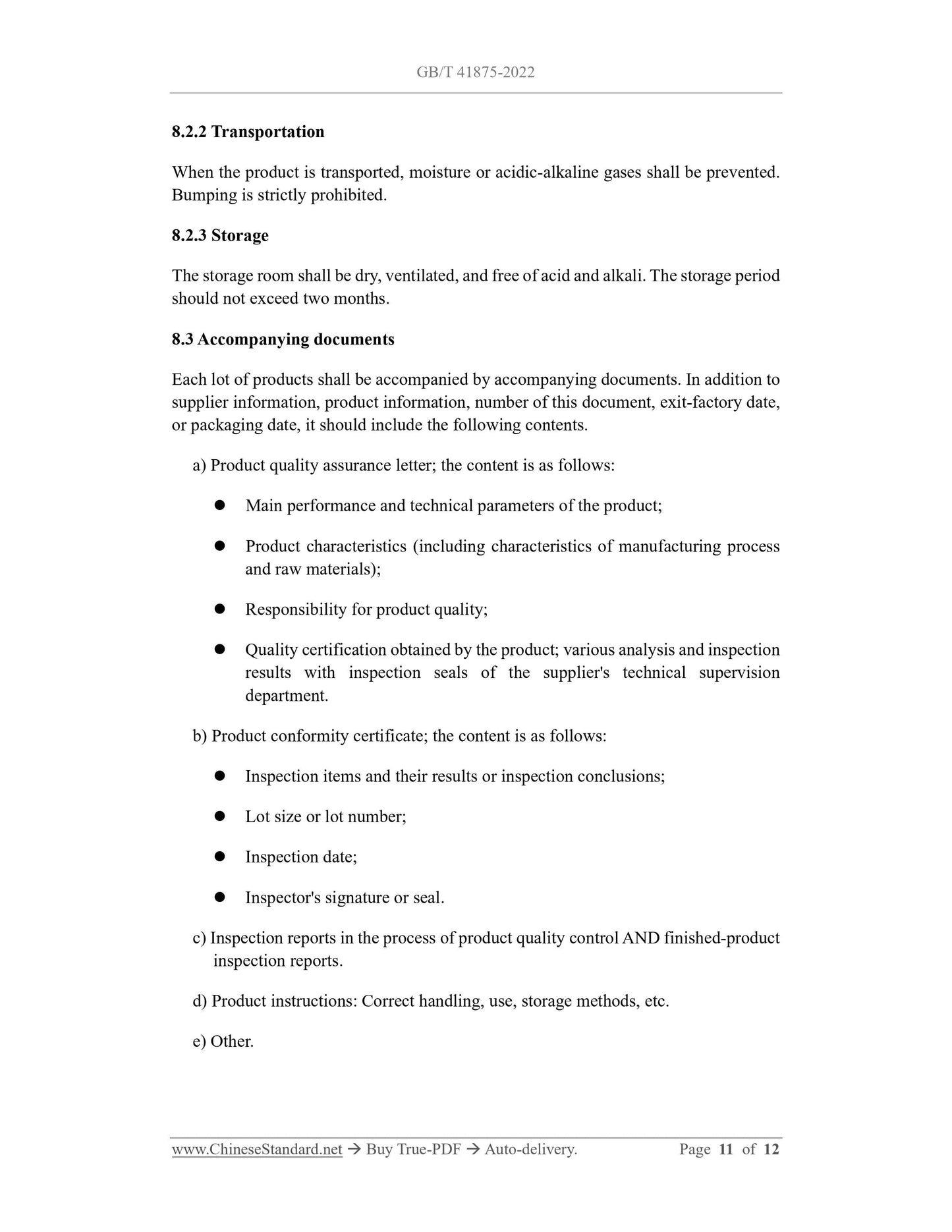

This document specifies the classification and marking, technical requirements, testmethods, inspection rules, marking, packaging, transportation, storage, accompanying

documents, and order form content of seamless thin-wall molybdenum tubes.

This document is applicable to seamless thin-wall molybdenum and molybdenum-alloy

tubes with a wall thickness not greater than 1.5 mm produced by pressure processing.

They are mainly used as nuclear cladding tubes, heat tubes, high-temperature fuel

protection tubes, draft tubes, tubular electrodes, thermocouple protection tubes, and

high-temperature furnace components, etc.

Basic Data

| Standard ID | GB/T 41875-2022 (GB/T41875-2022) |

| Description (Translated English) | Seamless thin-wall molybdenum tubes |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | H63 |

| Classification of International Standard | 77.150.99 |

| Word Count Estimation | 10,194 |

| Date of Issue | 2022-10-14 |

| Date of Implementation | 2023-05-01 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share