1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 41567-2022 English PDF (GB/T41567-2022)

GB/T 41567-2022 English PDF (GB/T41567-2022)

Regular price

$185.00

Regular price

Sale price

$185.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

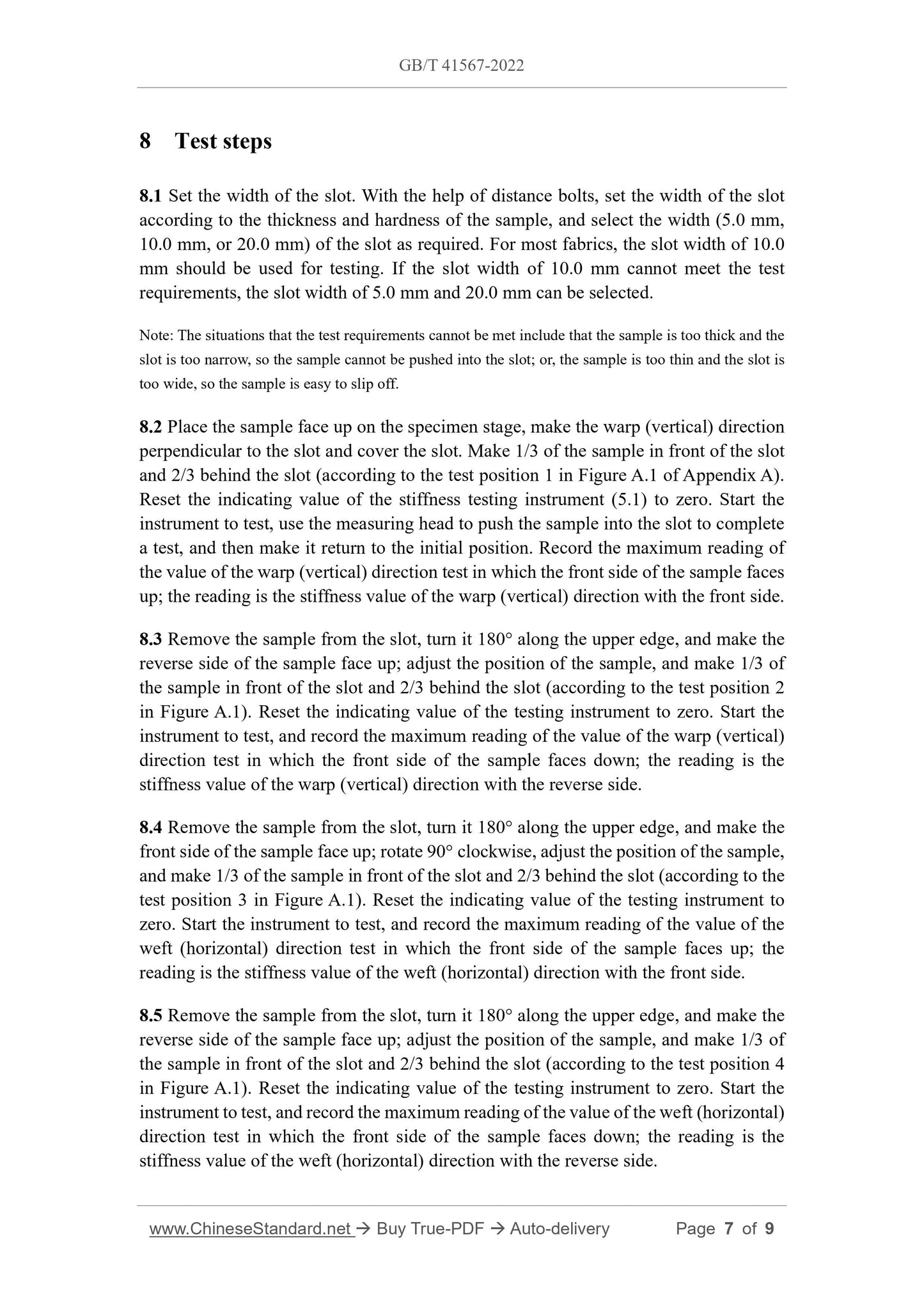

GB/T 41567-2022: Textiles - Determination of stiffness of fabrics - Slot method

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 41567-2022 (Self-service in 1-minute)

Newer / historical versions: GB/T 41567-2022

Preview True-PDF

Scope

This document describes the slot method for testing fabric stiffness.This document applies to all types of textile fabrics and their products.

Basic Data

| Standard ID | GB/T 41567-2022 (GB/T41567-2022) |

| Description (Translated English) | Textiles - Determination of stiffness of fabrics - Slot method |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | W04 |

| Word Count Estimation | 7,789 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share