1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 39181-2020 English PDF (GB/T39181-2020)

GB/T 39181-2020 English PDF (GB/T39181-2020)

Regular price

$205.00

Regular price

Sale price

$205.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

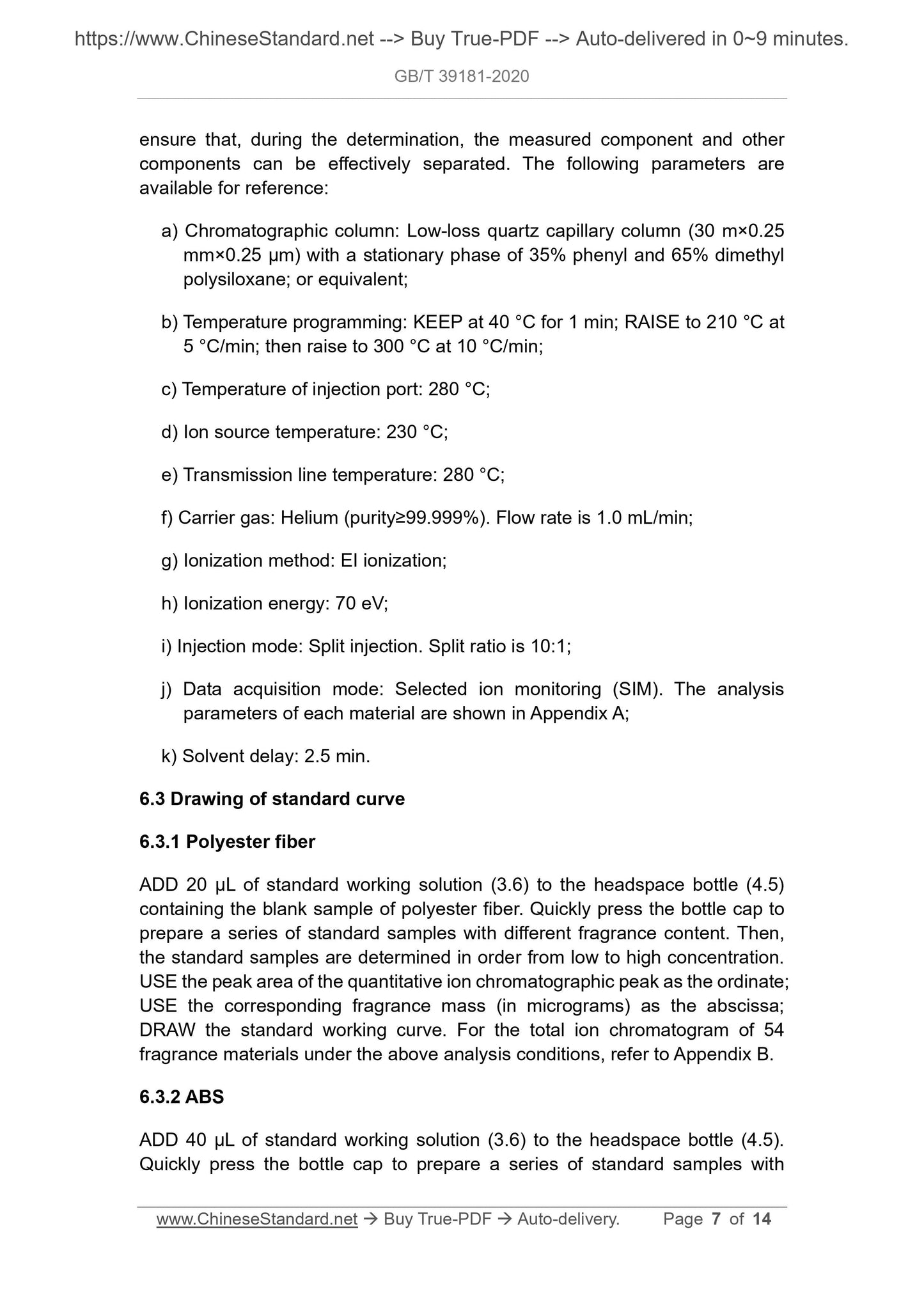

GB/T 39181-2020: Consumer products - Polyester fiber and ABS material - Rapid determination method of fragrance allergens

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 39181-2020 (Self-service in 1-minute)

Newer / historical versions: GB/T 39181-2020

Preview True-PDF

Scope

This Standard specifies the determination method of headspace gaschromatography-mass spectrometry for 54 kinds of fragrance allergens in

consumer product polyester fiber and acrylonitrile-butadiene-styrene (ABS)

material.

This Standard applies to the rapid determination of the content of 54 kinds of

fragrance allergens in consumer product polyester fiber and ABS material.

Basic Data

| Standard ID | GB/T 39181-2020 (GB/T39181-2020) |

| Description (Translated English) | Consumer products - Polyester fiber and ABS material - Rapid determination method of fragrance allergens |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | Y41 |

| Classification of International Standard | 13.120 |

| Word Count Estimation | 14,192 |

| Date of Issue | 2020-10-21 |

| Date of Implementation | 2020-10-21 |

| Regulation (derived from) | National Standard Announcement No. 22 of 2020 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share