1

/

of

11

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 38823-2020 English PDF (GB/T38823-2020)

GB/T 38823-2020 English PDF (GB/T38823-2020)

Regular price

$260.00

Regular price

Sale price

$260.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 38823-2020: Silicon-carbon

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 38823-2020 (Self-service in 1-minute)

Newer / historical versions: GB/T 38823-2020

Preview True-PDF

Scope

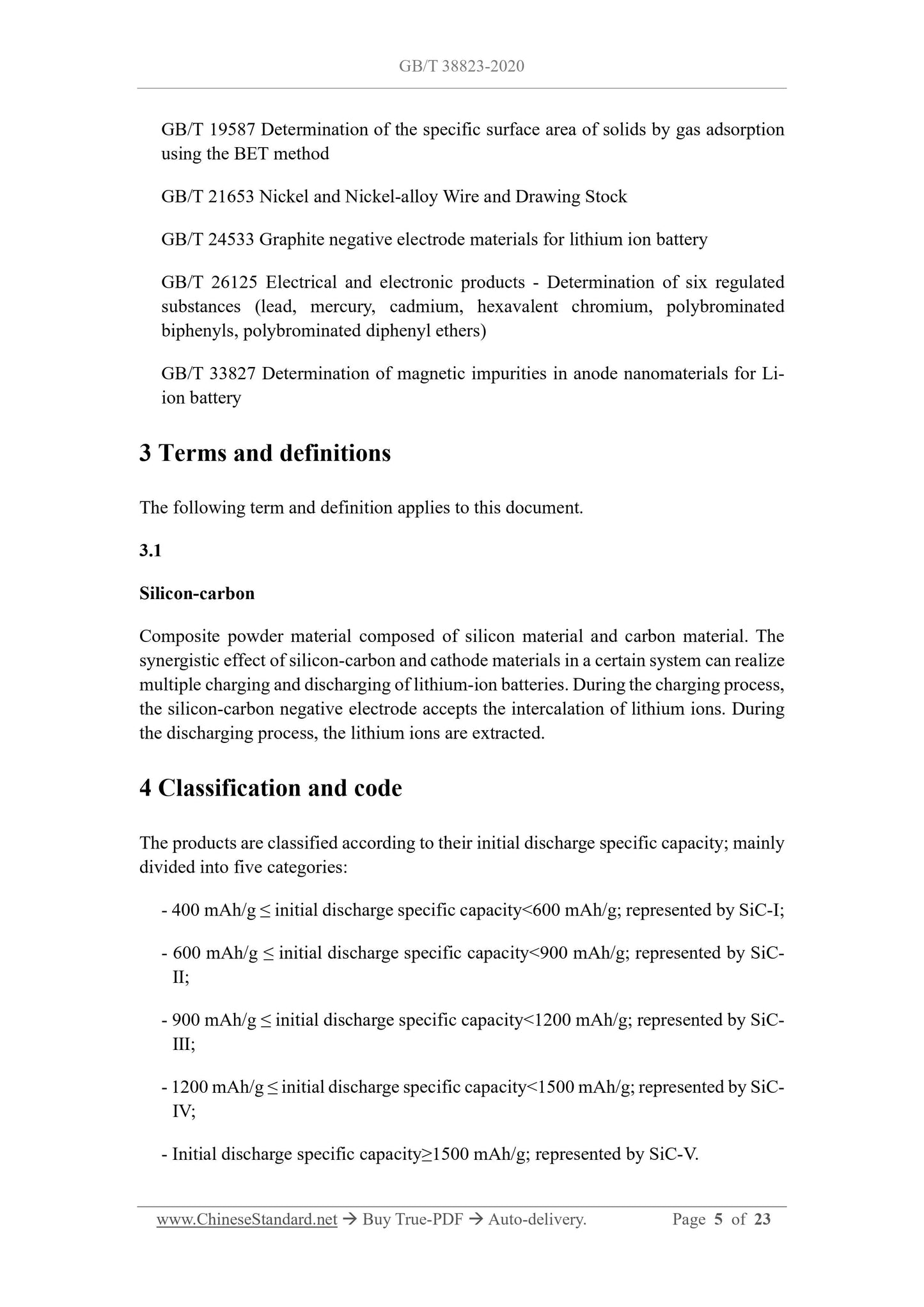

This Standard specifies the terms and definitions, classification and code, technicalrequirements, test methods, inspection rules, packaging, marking, transportation, and

storage of silicon-carbon.

This Standard applies to all kinds of silicon-carbon anode materials for lithium-ion

batteries.

Basic Data

| Standard ID | GB/T 38823-2020 (GB/T38823-2020) |

| Description (Translated English) | Silicon-carbon |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | Q50 |

| Classification of International Standard | 29.050 |

| Word Count Estimation | 18,18 |

| Date of Issue | 2020-06-02 |

| Date of Implementation | 2020-12-01 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share