1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 37632-2019 English PDF (GB/T37632-2019)

GB/T 37632-2019 English PDF (GB/T37632-2019)

Regular price

$175.00

Regular price

Sale price

$175.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 37632-2019: Man-Made Fiber - Test Method for Titanium Dioxide Content

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 37632-2019 (Self-service in 1-minute)

Newer / historical versions: GB/T 37632-2019

Preview True-PDF

Scope

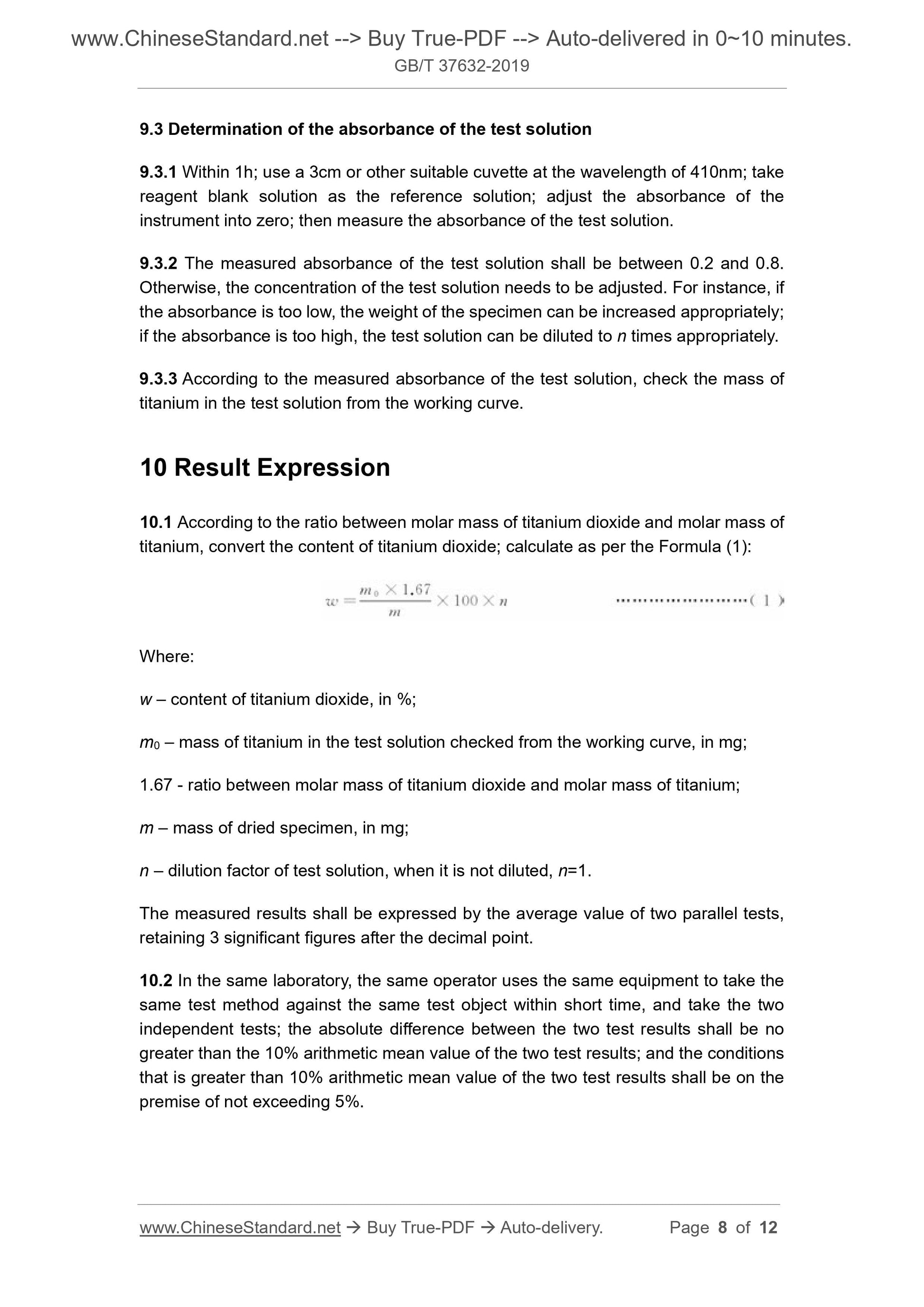

This Standard specifies the test method for determination of titanium dioxide contentin man-made fibers by spectrophotometry.

This Standard is applicable to the man-made fibers; thereof, the functional man-made

fibers can use it as a reference.

Basic Data

| Standard ID | GB/T 37632-2019 (GB/T37632-2019) |

| Description (Translated English) | Man-Made Fiber - Test Method for Titanium Dioxide Content |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | W50 |

| Classification of International Standard | 59.060.20 |

| Word Count Estimation | 10,187 |

| Date of Issue | 2019-06-04 |

| Date of Implementation | 2020-01-01 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share