1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 37610-2019 English PDF (GB/T37610-2019)

GB/T 37610-2019 English PDF (GB/T37610-2019)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

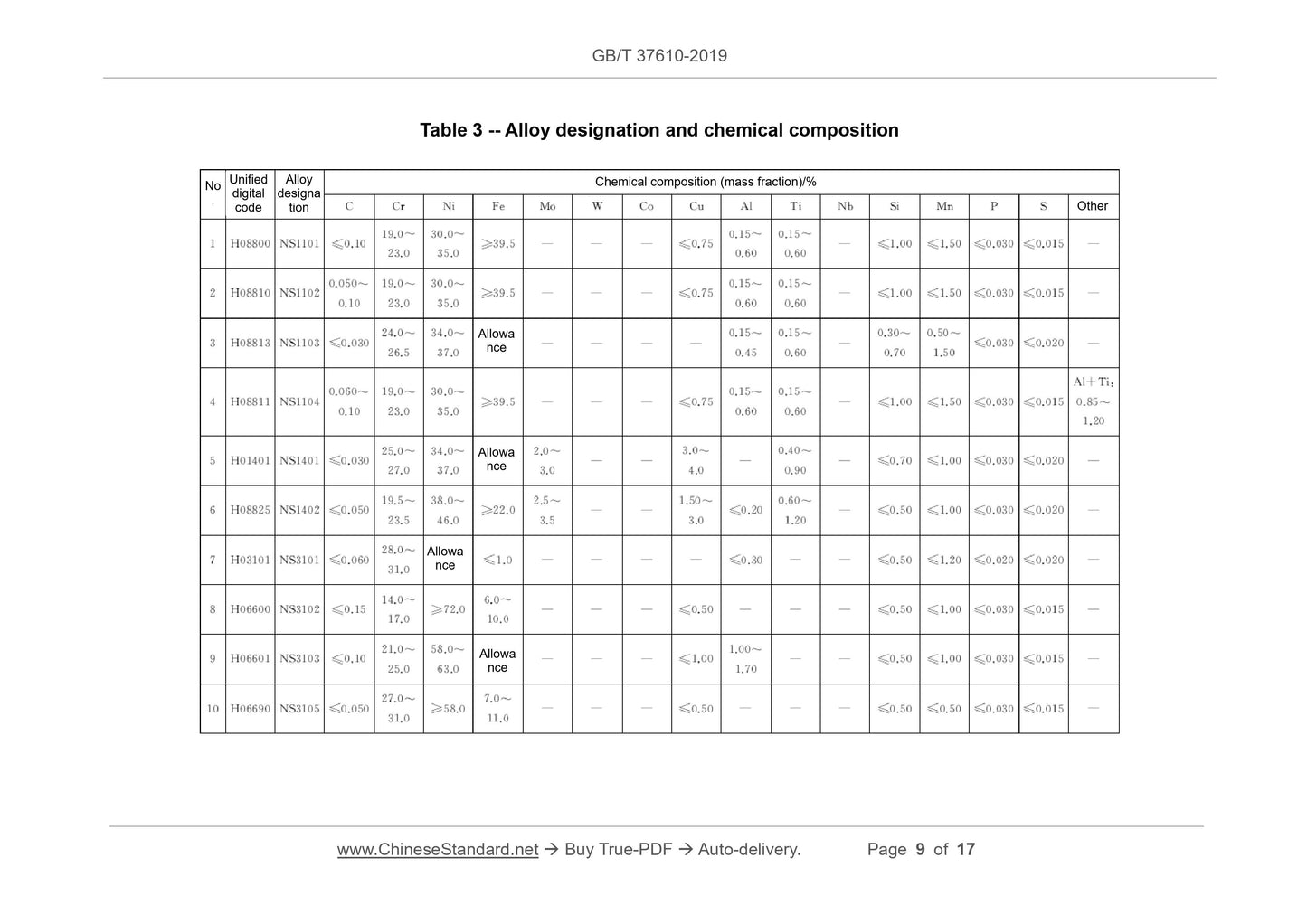

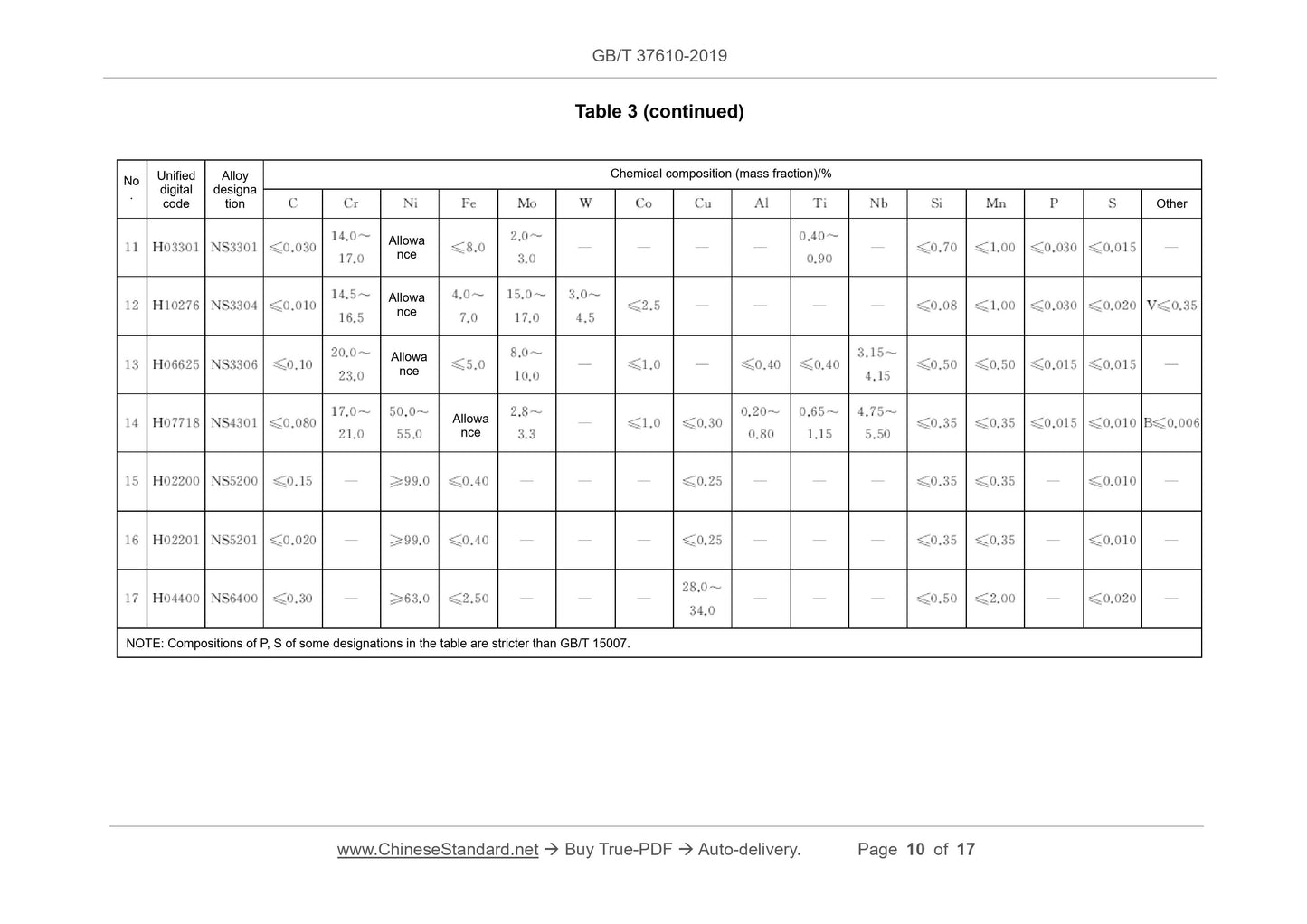

GB/T 37610-2019: Corrosion-resistant alloy small diameter precision seamless tubes

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 37610-2019 (Self-service in 1-minute)

Newer / historical versions: GB/T 37610-2019

Preview True-PDF

Scope

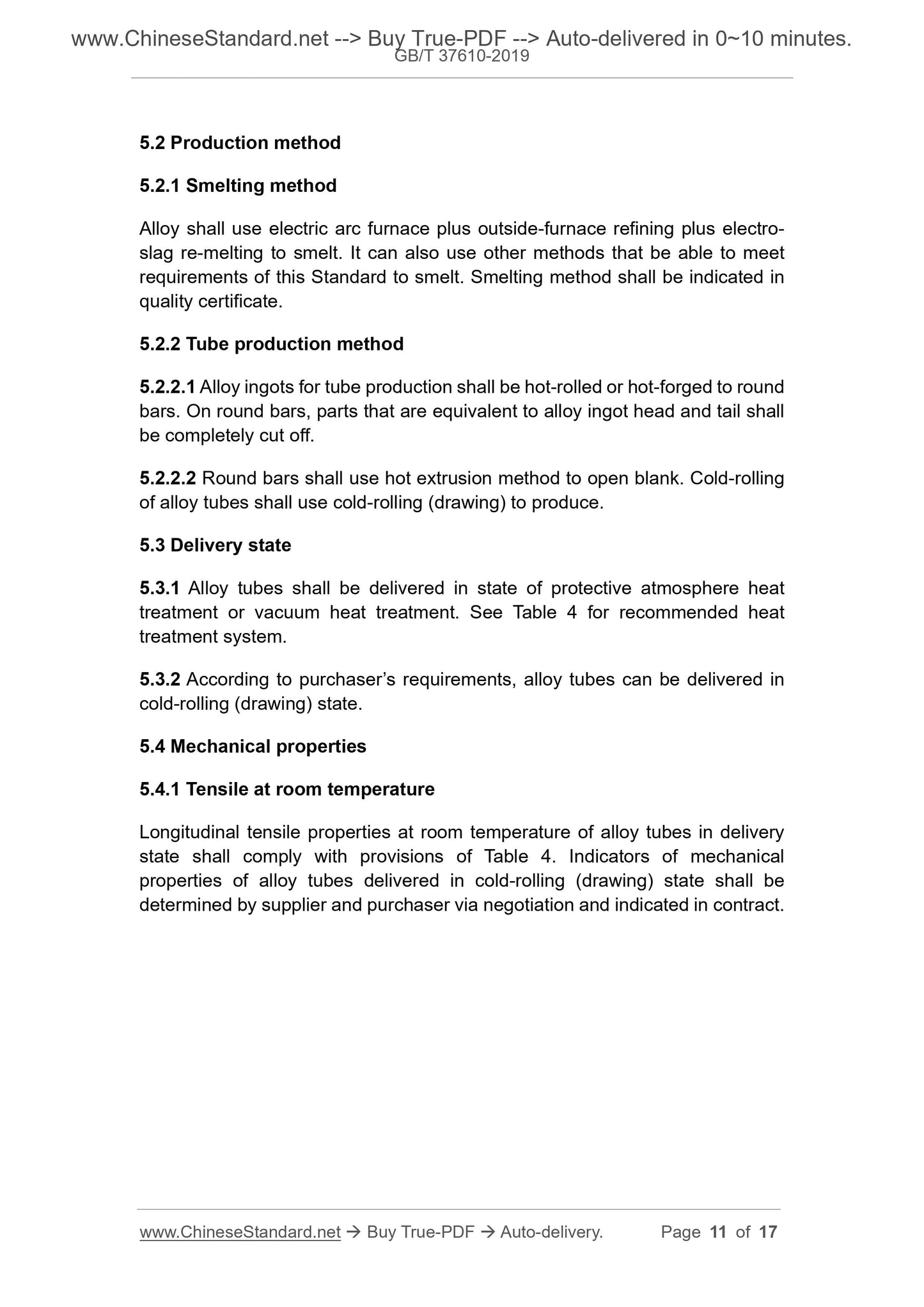

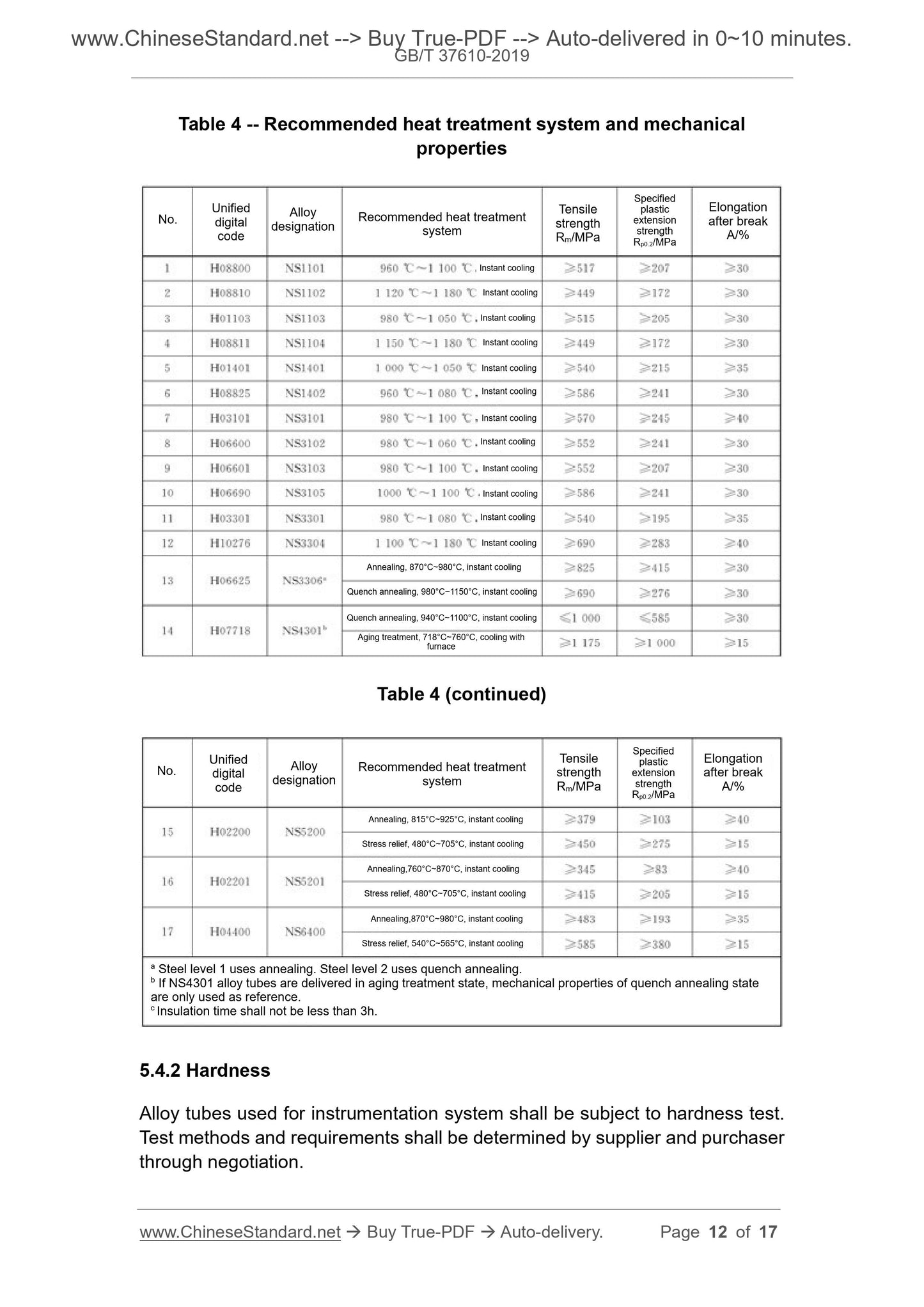

This Standard specifies order content, size, appearance, technicalrequirements, test methods, inspection rules, packaging, marks and quality

certificate of corrosion-resistant alloy small diameter precision seamless tubes.

This Standard is applicable to corrosion-resistant alloy cold-rolled (drawn) small

diameter precision seamless tubes such as nickel based, iron nickel based,

pure nickel and nickel copper of which nominal outer diameter is 3mm~30mm,

and wall thickness is 0.3mm~3.0mm (hereinafter referred to as alloy tubes).

Basic Data

| Standard ID | GB/T 37610-2019 (GB/T37610-2019) |

| Description (Translated English) | Corrosion-resistant alloy small diameter precision seamless tubes |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | H59 |

| Classification of International Standard | 77.140.99; 77.140.75 |

| Word Count Estimation | 14,143 |

| Date of Issue | 2019-06-04 |

| Date of Implementation | 2020-05-01 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share