1

/

of

11

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 36668.1-2018 English PDF (GB/T36668.1-2018)

GB/T 36668.1-2018 English PDF (GB/T36668.1-2018)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

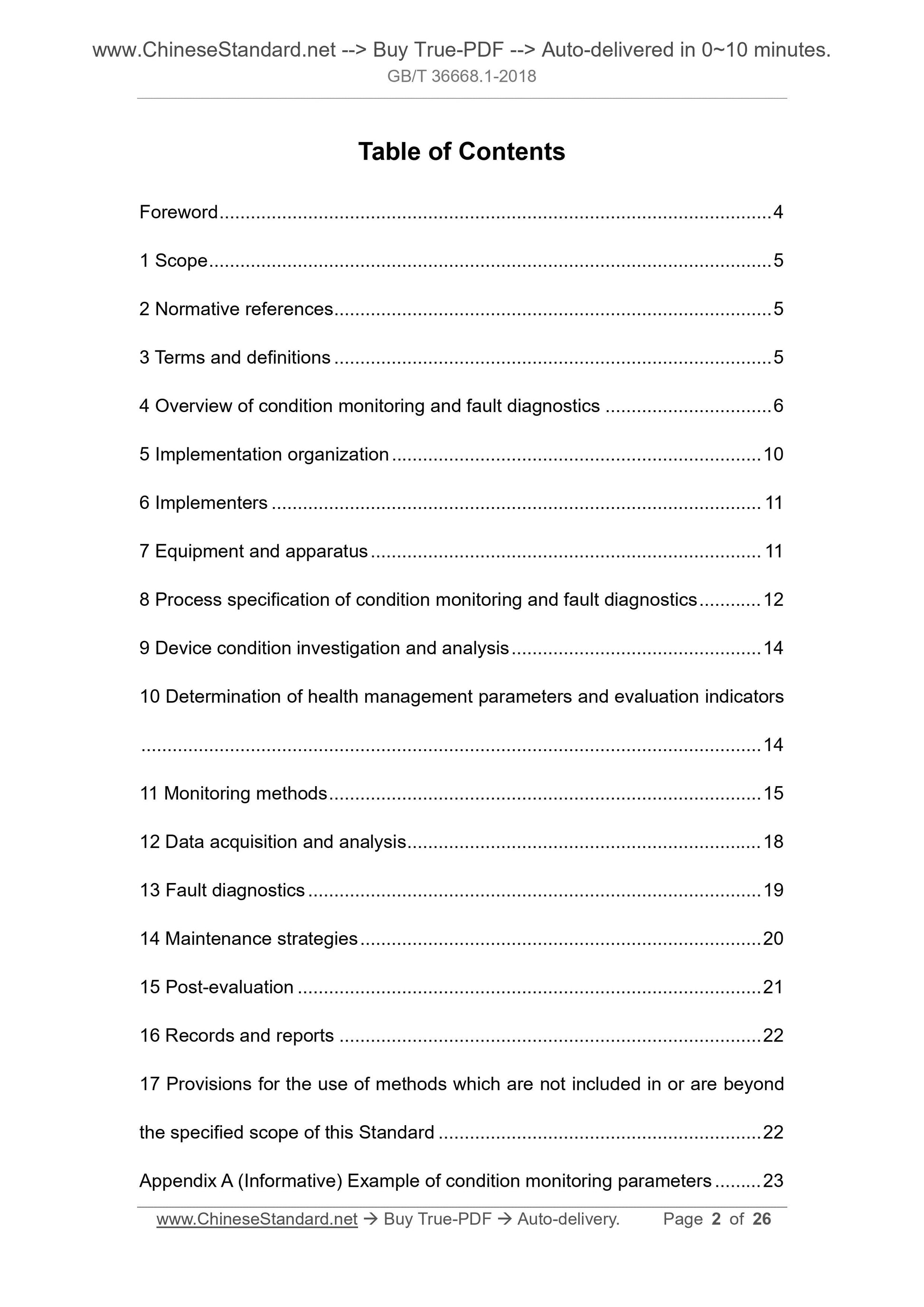

GB/T 36668.1-2018: Condition monitoring and fault diagnostics of amusement device - Part 1: General requirements

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 36668.1-2018 (Self-service in 1-minute)

Newer / historical versions: GB/T 36668.1-2018

Preview True-PDF

Scope

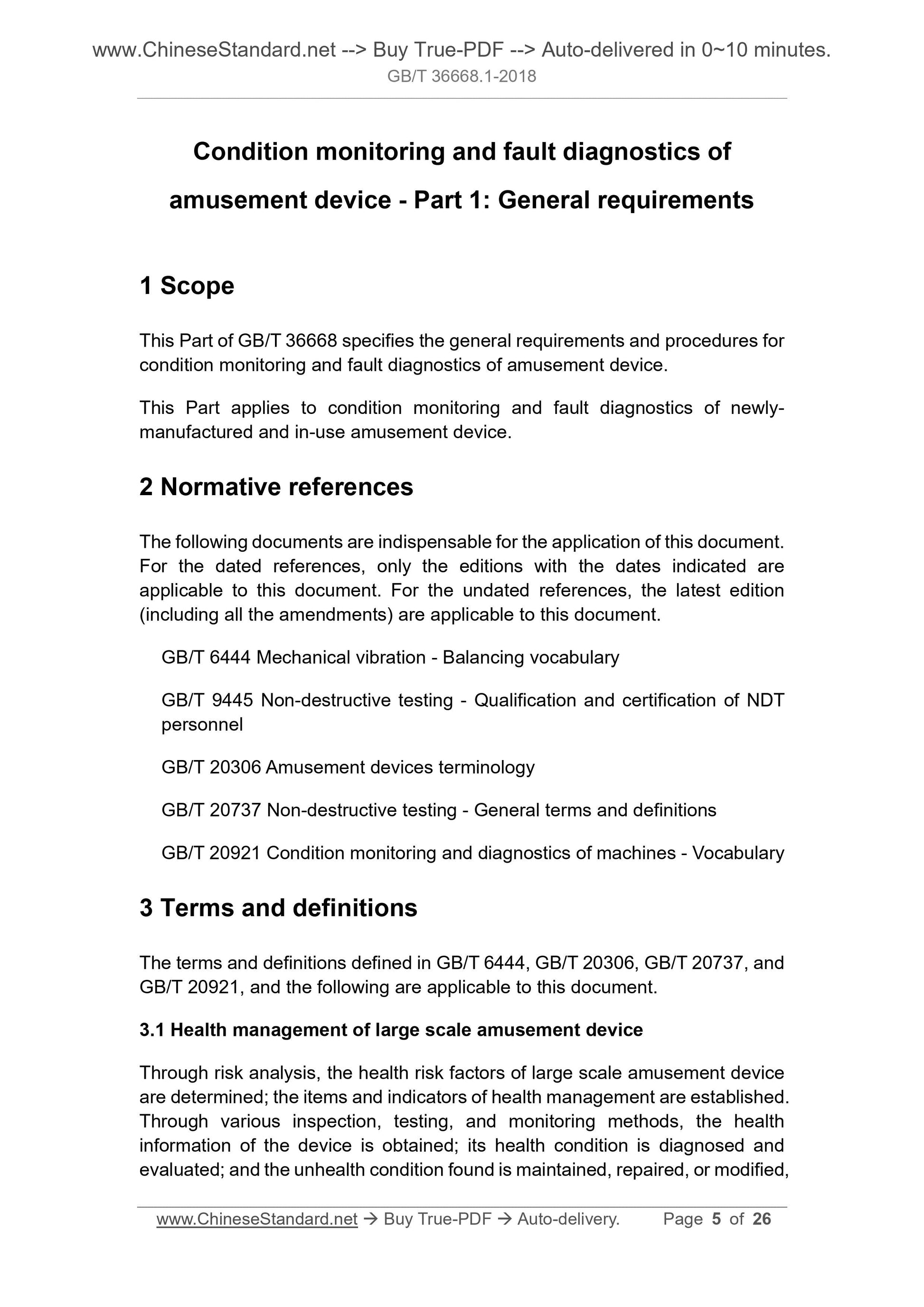

This Part of GB/T 36668 specifies the general requirements and procedures forcondition monitoring and fault diagnostics of amusement device.

This Part applies to condition monitoring and fault diagnostics of newly-

manufactured and in-use amusement device.

Basic Data

| Standard ID | GB/T 36668.1-2018 (GB/T36668.1-2018) |

| Description (Translated English) | Condition monitoring and fault diagnostics of amusement device - Part 1: General requirements |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | Y57 |

| Classification of International Standard | 97.200.40 |

| Word Count Estimation | 18,153 |

| Date of Issue | 2018-09-28 |

| Date of Implementation | 2019-04-01 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share