1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 36260-2018 English PDF (GB/T36260-2018)

GB/T 36260-2018 English PDF (GB/T36260-2018)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 36260-2018: Anti-Glare and Anti-Reflective Glass for Electronic Display

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 36260-2018 (Self-service in 1-minute)

Newer / historical versions: GB/T 36260-2018

Preview True-PDF

Scope

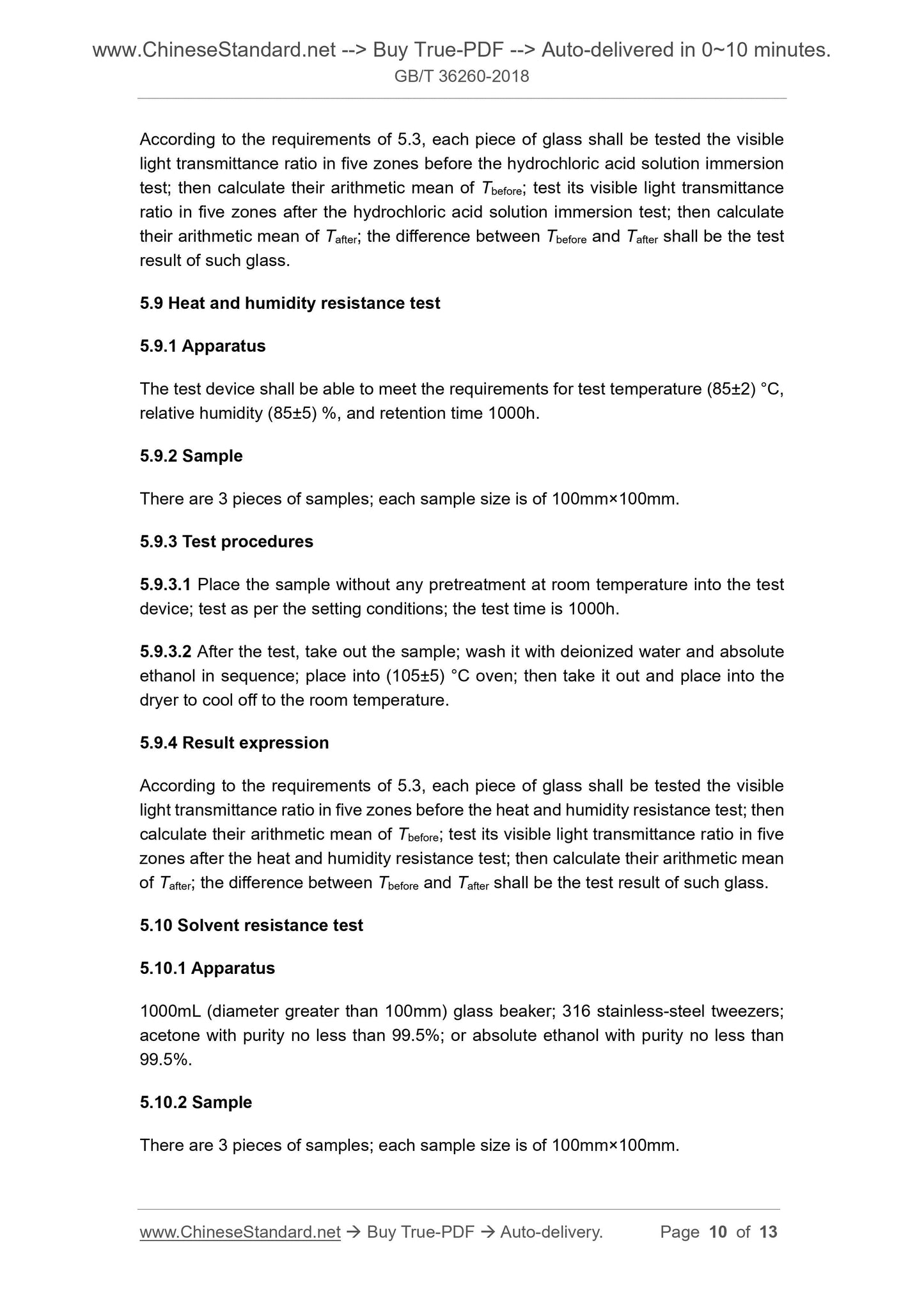

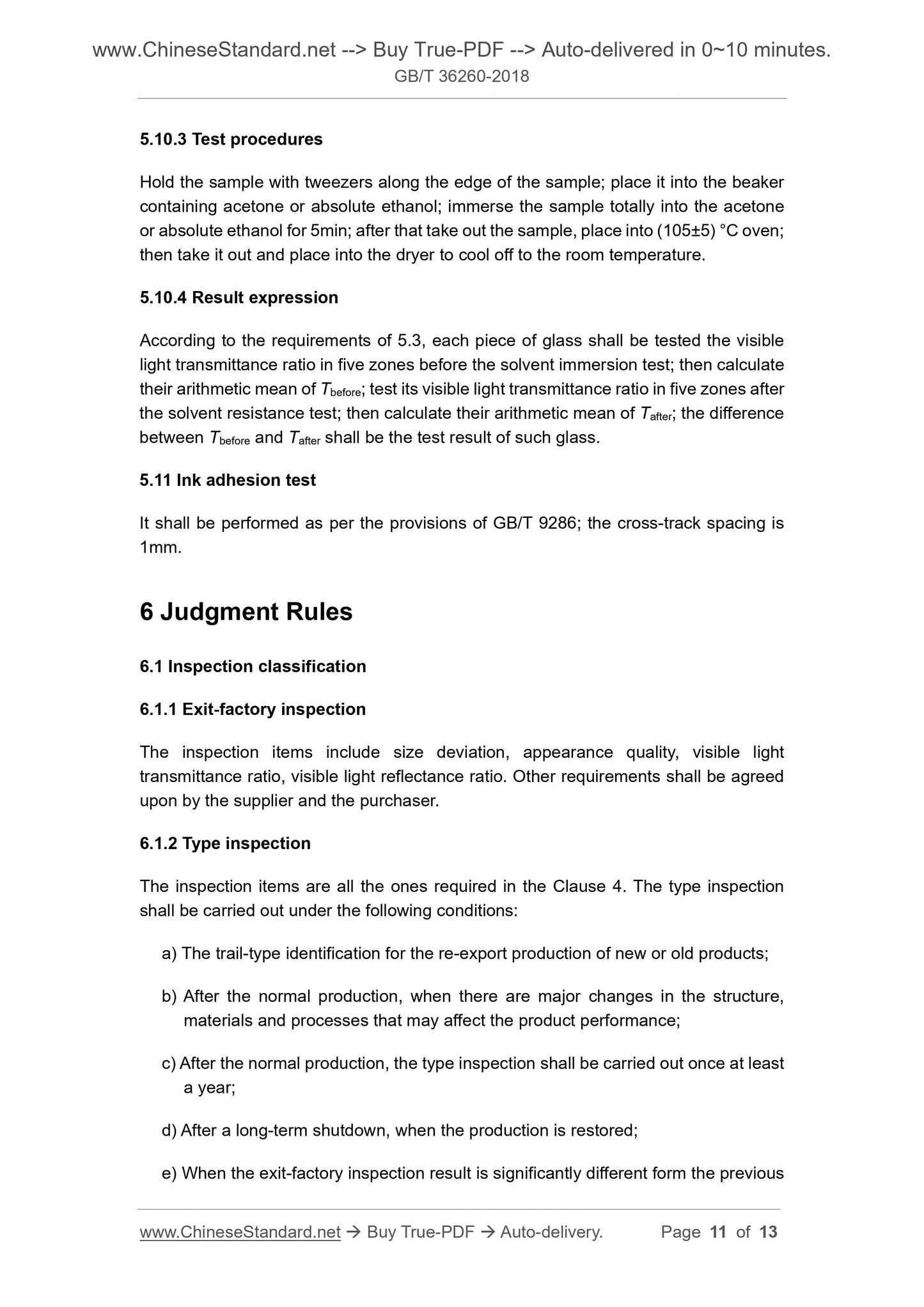

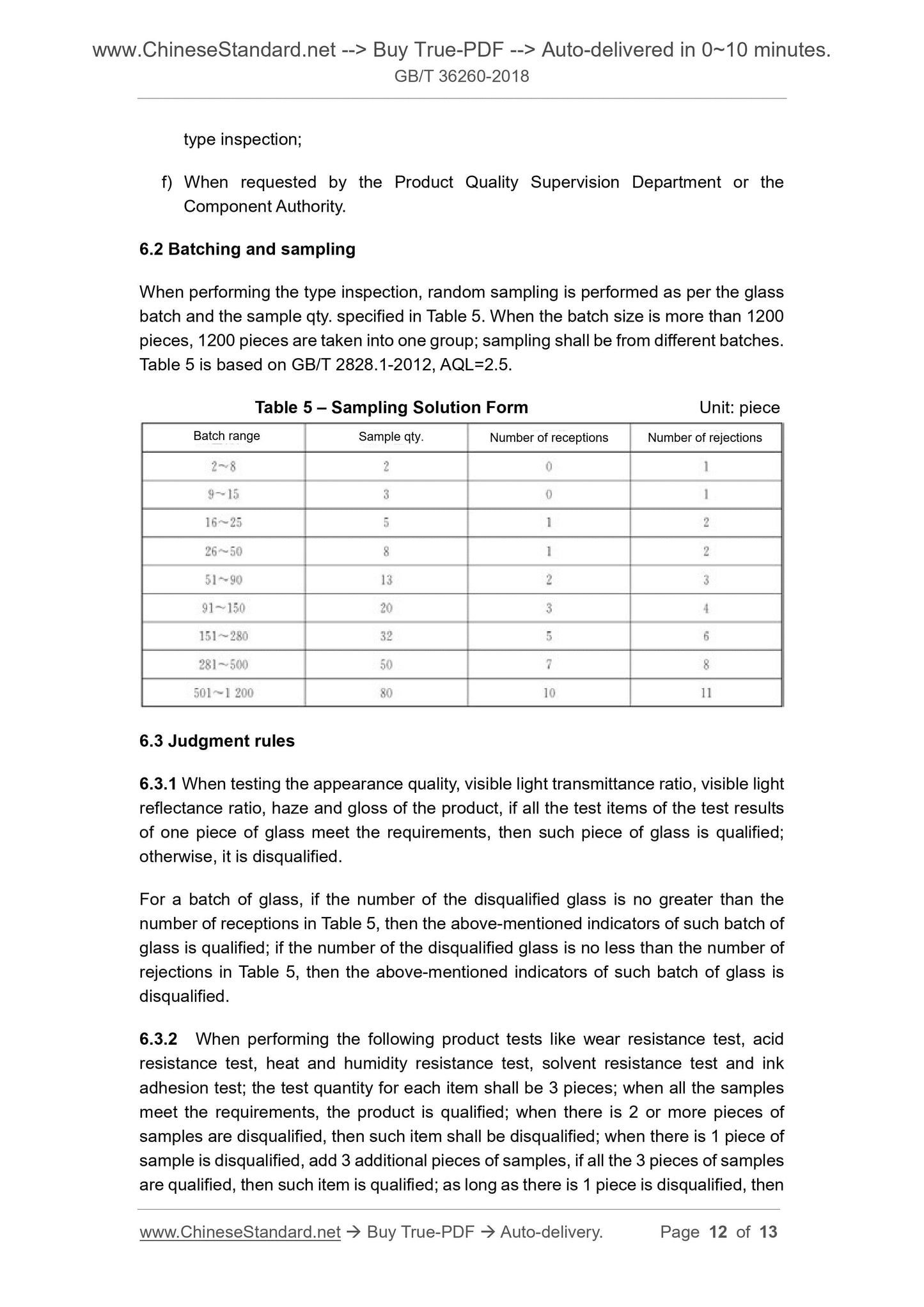

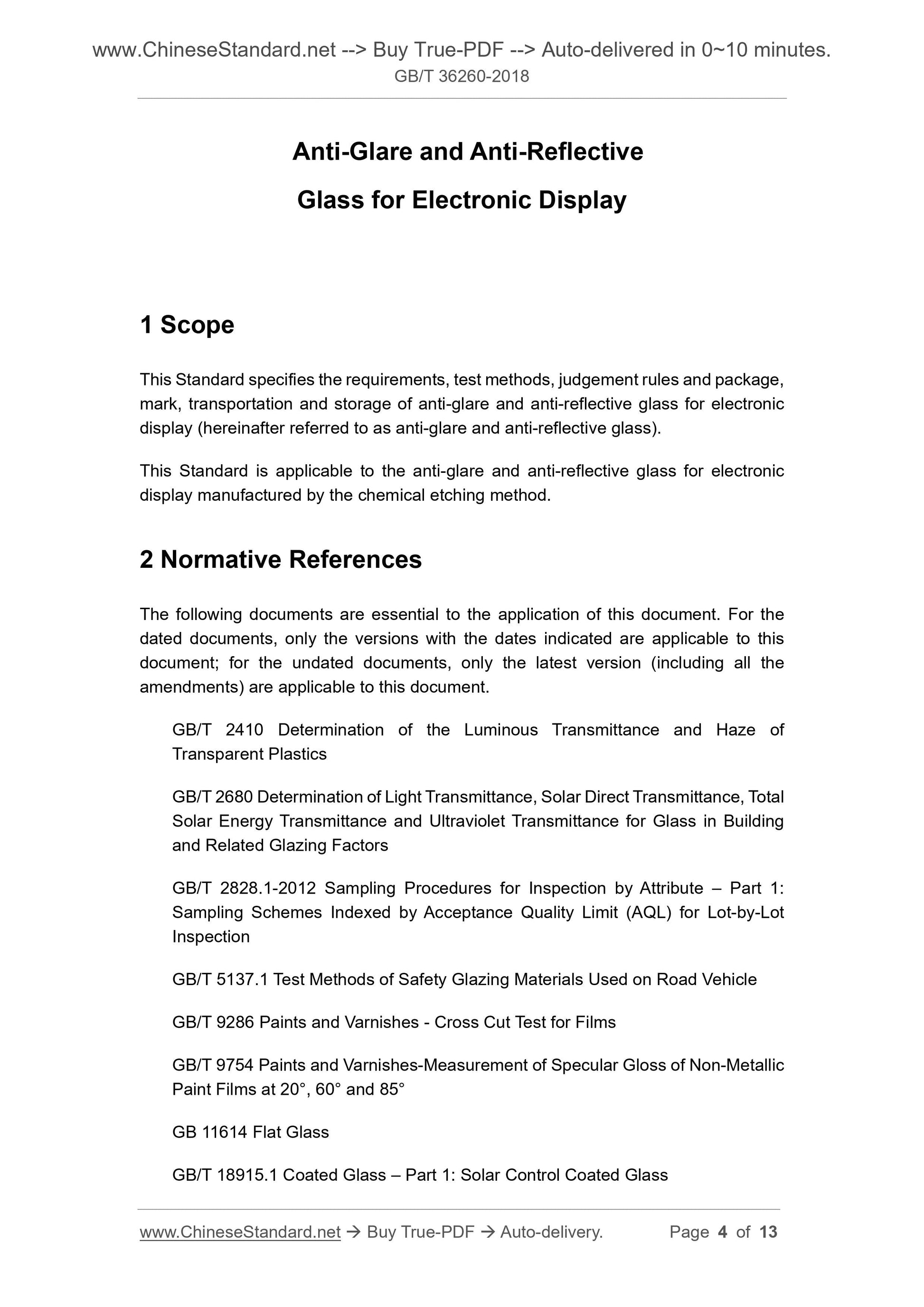

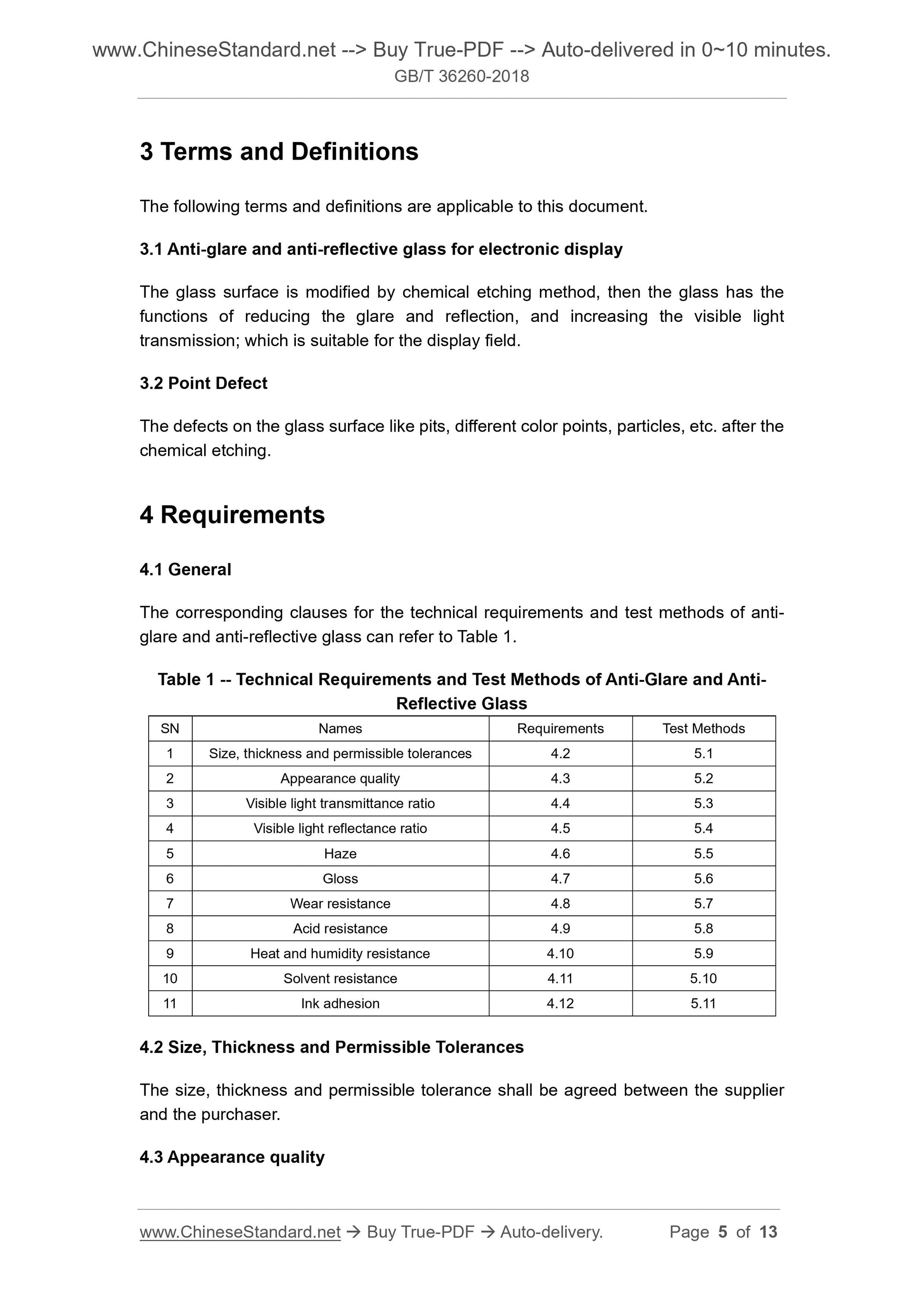

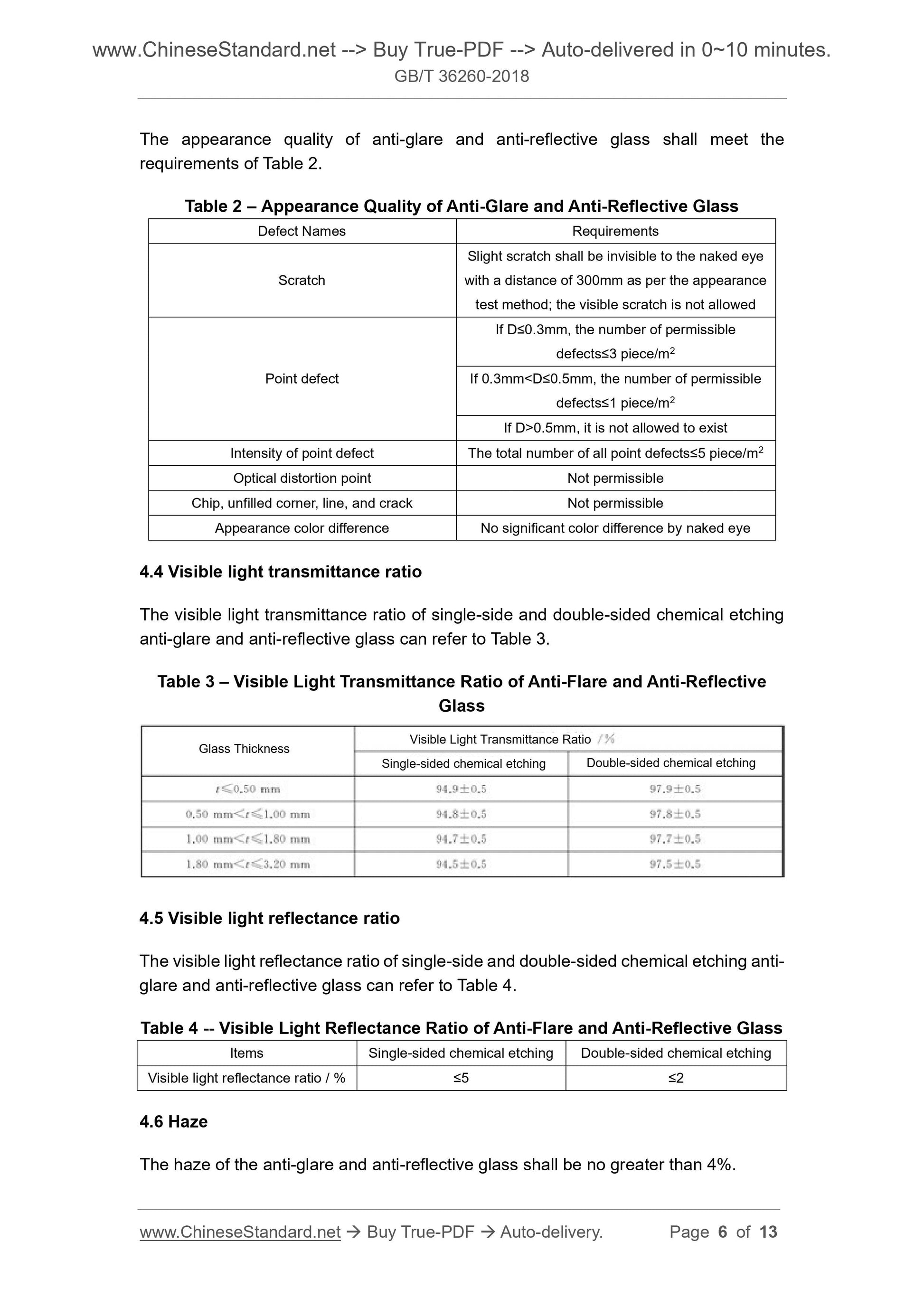

This Standard specifies the requirements, test methods, judgement rules and package,mark, transportation and storage of anti-glare and anti-reflective glass for electronic

display (hereinafter referred to as anti-glare and anti-reflective glass).

This Standard is applicable to the anti-glare and anti-reflective glass for electronic

display manufactured by the chemical etching method.

Basic Data

| Standard ID | GB/T 36260-2018 (GB/T36260-2018) |

| Description (Translated English) | Anti-Glare and Anti-Reflective Glass for Electronic Display |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | Q34 |

| Classification of International Standard | 81.040.30 |

| Word Count Estimation | 10,131 |

| Date of Issue | 2018-06-07 |

| Date of Implementation | 2019-05-01 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share