1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 35505-2017 English PDF (GB/T35505-2017)

GB/T 35505-2017 English PDF (GB/T35505-2017)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 35505-2017: Technical Specification for Sherardizing Coatings on Iron and Steel Articles

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 35505-2017 (Self-service in 1-minute)

Newer / historical versions: GB/T 35505-2017

Preview True-PDF

Scope

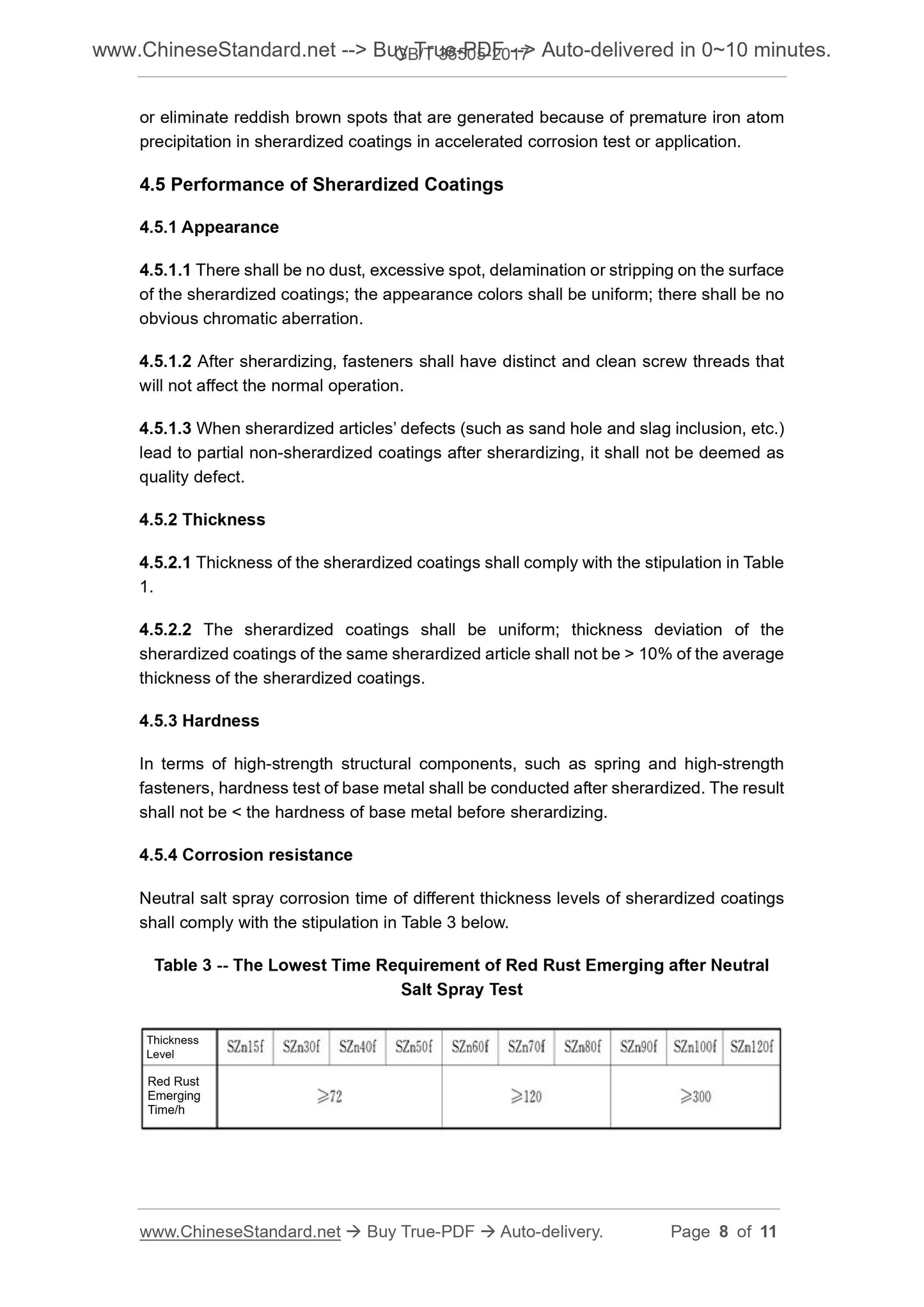

This Standard specifies relevant terms, and technical requirements of quality controland assessment of sherardizing coatings anti-corrosion operation of iron and steel

articles (hereinafter referred to as sherardizing operation).

This Standard is applicable to surface sherardizing operation of carbon steel, low-alloy

steel and cast-iron components, fasteners and structural parts.

This Standard is not applicable to sherardizing operation of steel structural

components that have precision requirements towards external dimension; steel

structural components that bear soldered joints or organic material joints; steel

structural components that need to be tempered at the temperature of 360 °C to satisfy

the requirement of mechanical properties.

Basic Data

| Standard ID | GB/T 35505-2017 (GB/T35505-2017) |

| Description (Translated English) | Technical Specification for Sherardizing Coatings on Iron and Steel Articles |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | A29 |

| Classification of International Standard | 25.220.99 |

| Word Count Estimation | 10,129 |

| Date of Issue | 2017-12-29 |

| Date of Implementation | 2018-07-01 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

Share