1

/

of

11

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 3521-2023 English PDF (GB/T3521-2023)

GB/T 3521-2023 English PDF (GB/T3521-2023)

Regular price

$380.00

Regular price

Sale price

$380.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

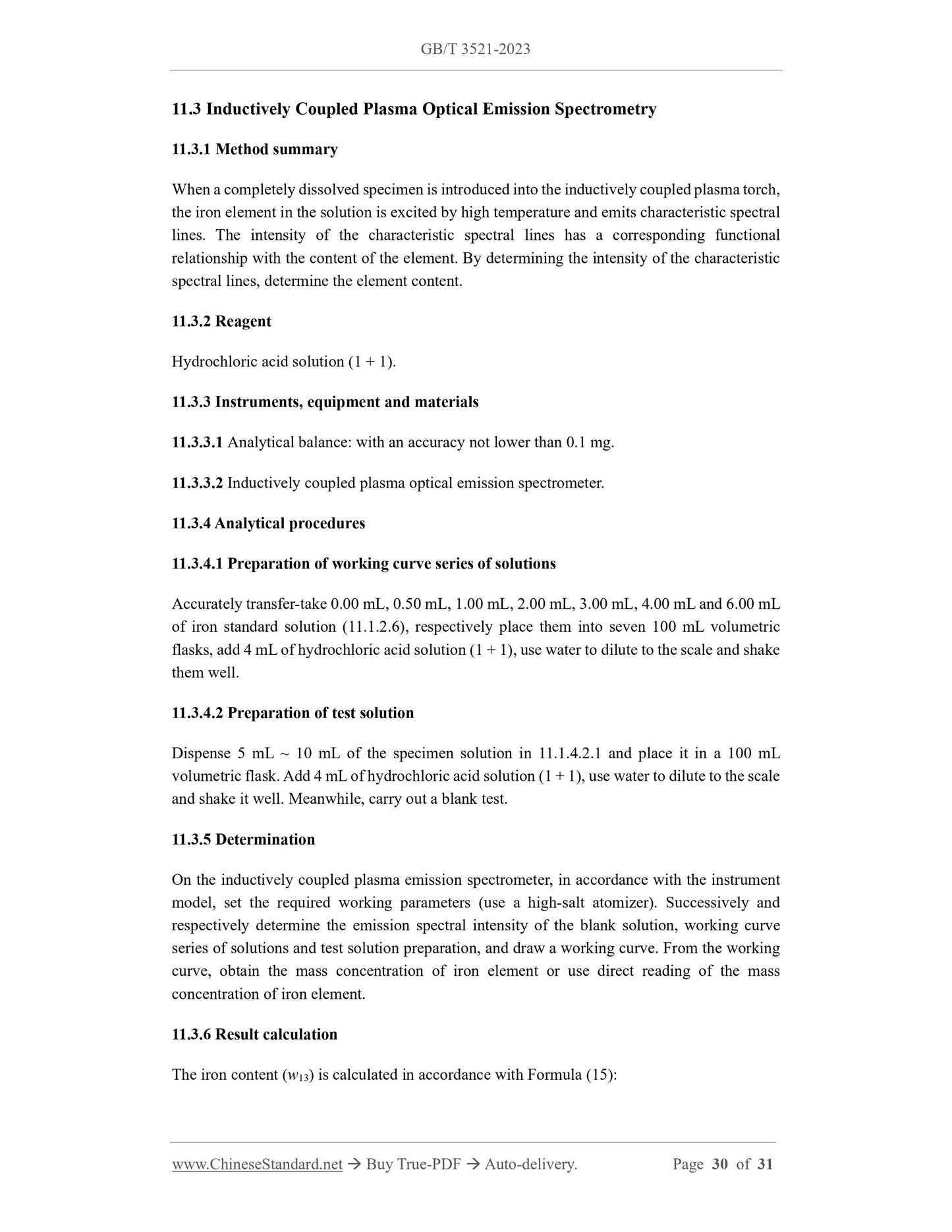

GB/T 3521-2023: Methods for chemical analysis of graphite

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 3521-2023 (Self-service in 1-minute)

Newer / historical versions: GB/T 3521-2023

Preview True-PDF

Scope

This document describes methods for the analysis of moisture, volatile matter, ash content,fixed carbon content, sulfur content, acid-soluble iron content and iron content of graphite

products.

This document is applicable to the chemical analysis of natural graphite products.

Basic Data

| Standard ID | GB/T 3521-2023 (GB/T3521-2023) |

| Description (Translated English) | Methods for chemical analysis of graphite |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | Q51 |

| Classification of International Standard | 73.080 |

| Word Count Estimation | 22,242 |

| Date of Issue | 2023-12-28 |

| Date of Implementation | 2024-07-01 |

| Older Standard (superseded by this standard) | GB/T 3521-2008 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share