1

/

of

8

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 34493-2017 English PDF (GB/T34493-2017)

GB/T 34493-2017 English PDF (GB/T34493-2017)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 34493-2017: Aluminium Alloys Extruded Rods for Easy-cutting

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 34493-2017 (Self-service in 1-minute)

Newer / historical versions: GB/T 34493-2017

Preview True-PDF

Scope

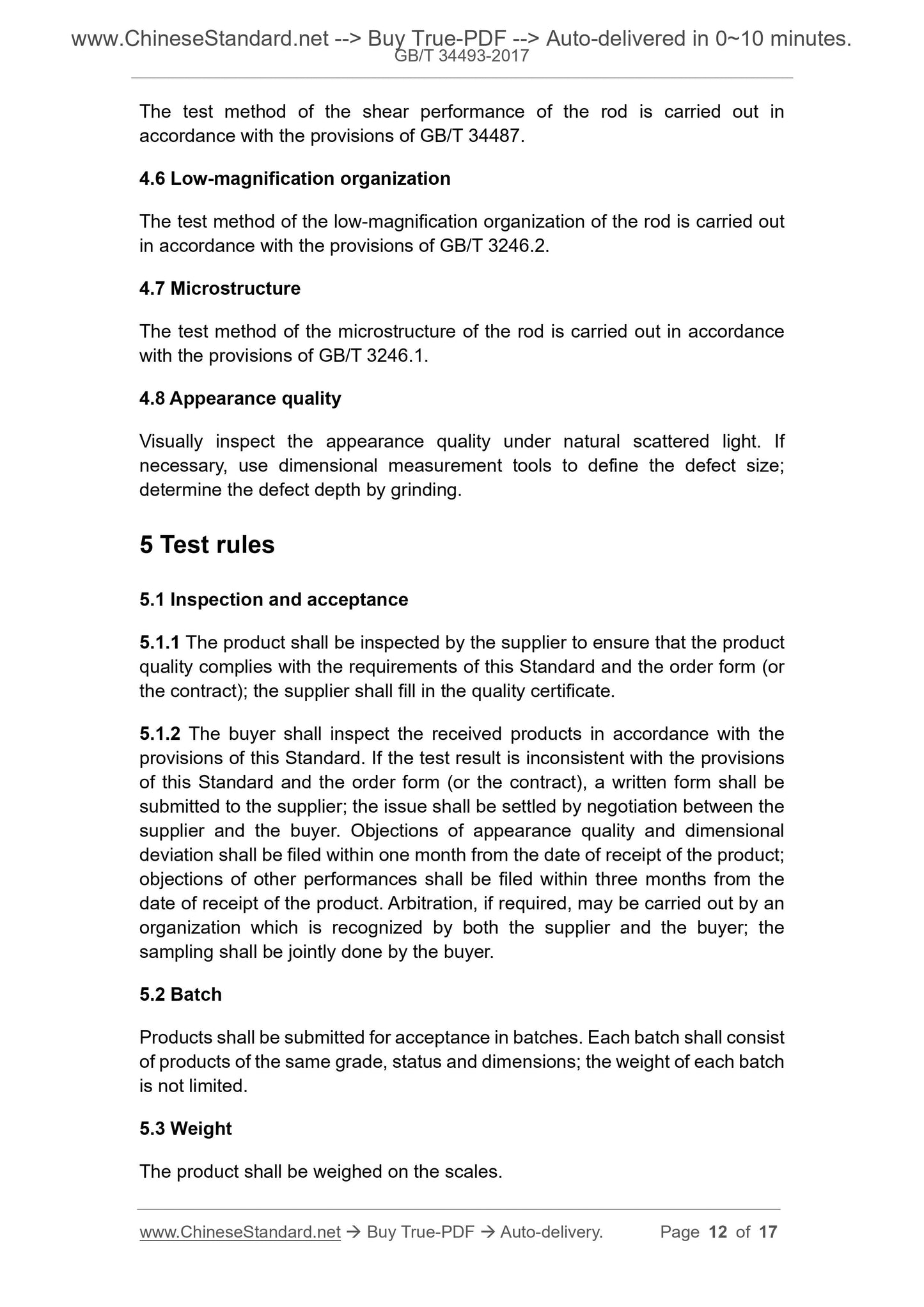

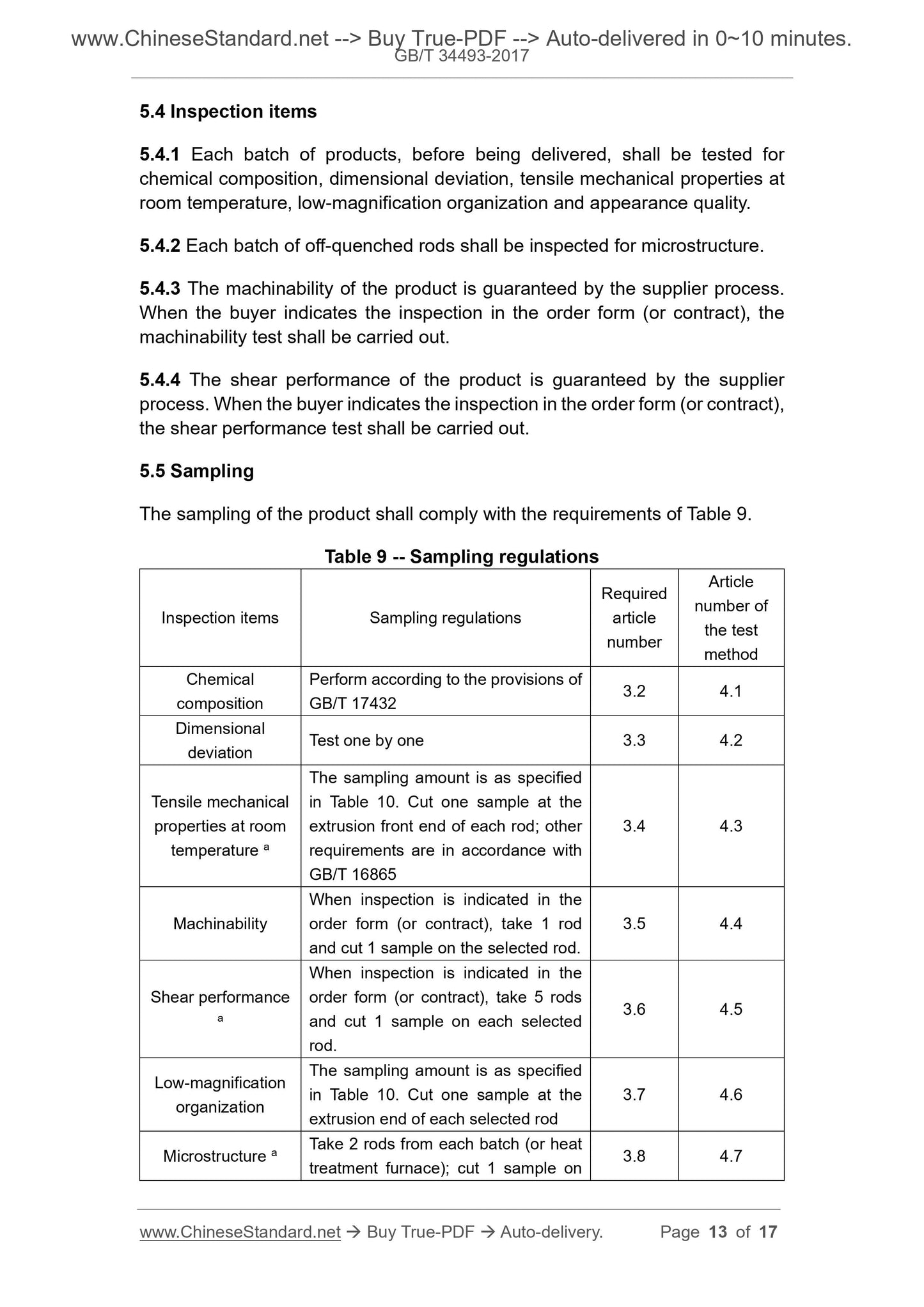

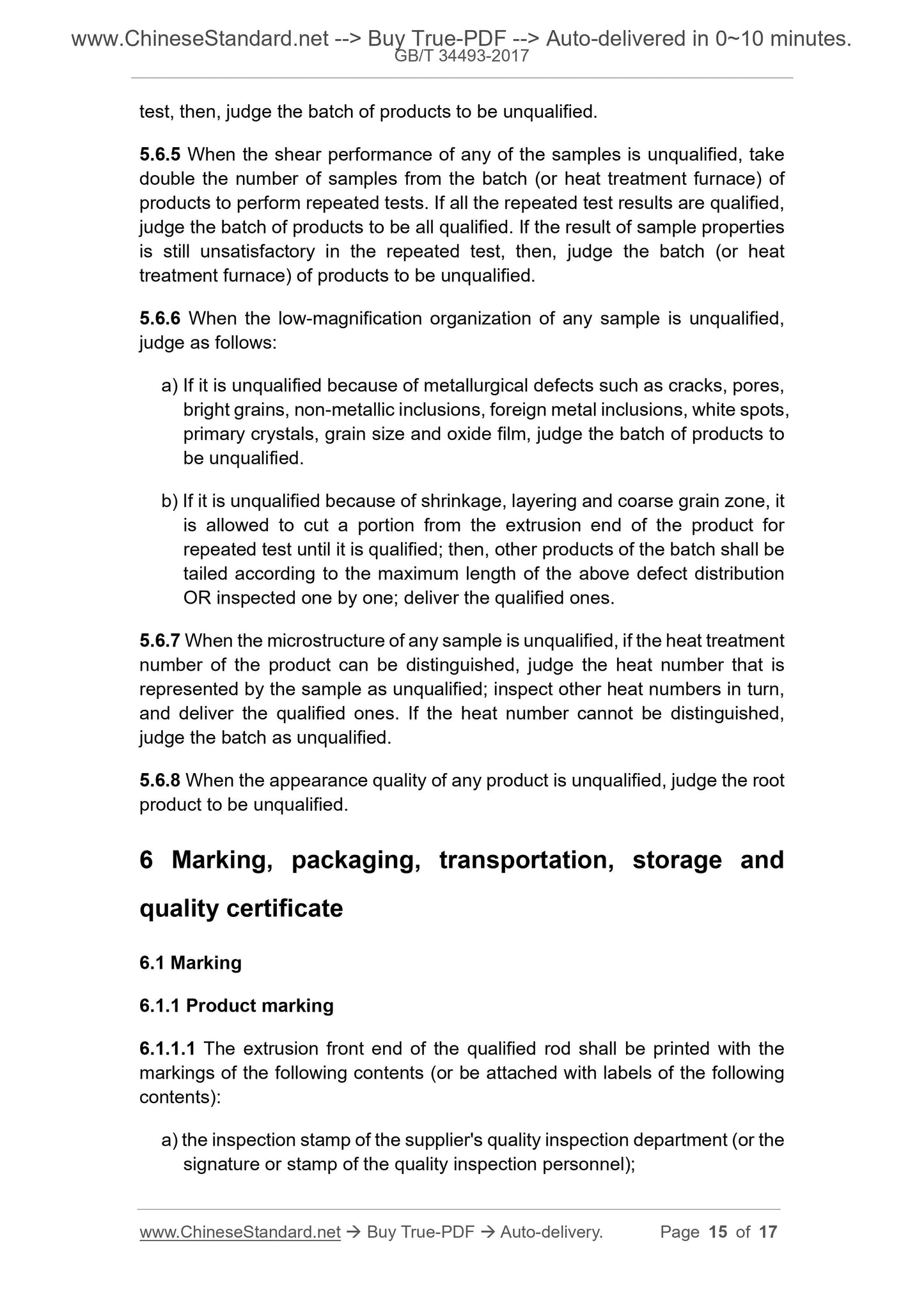

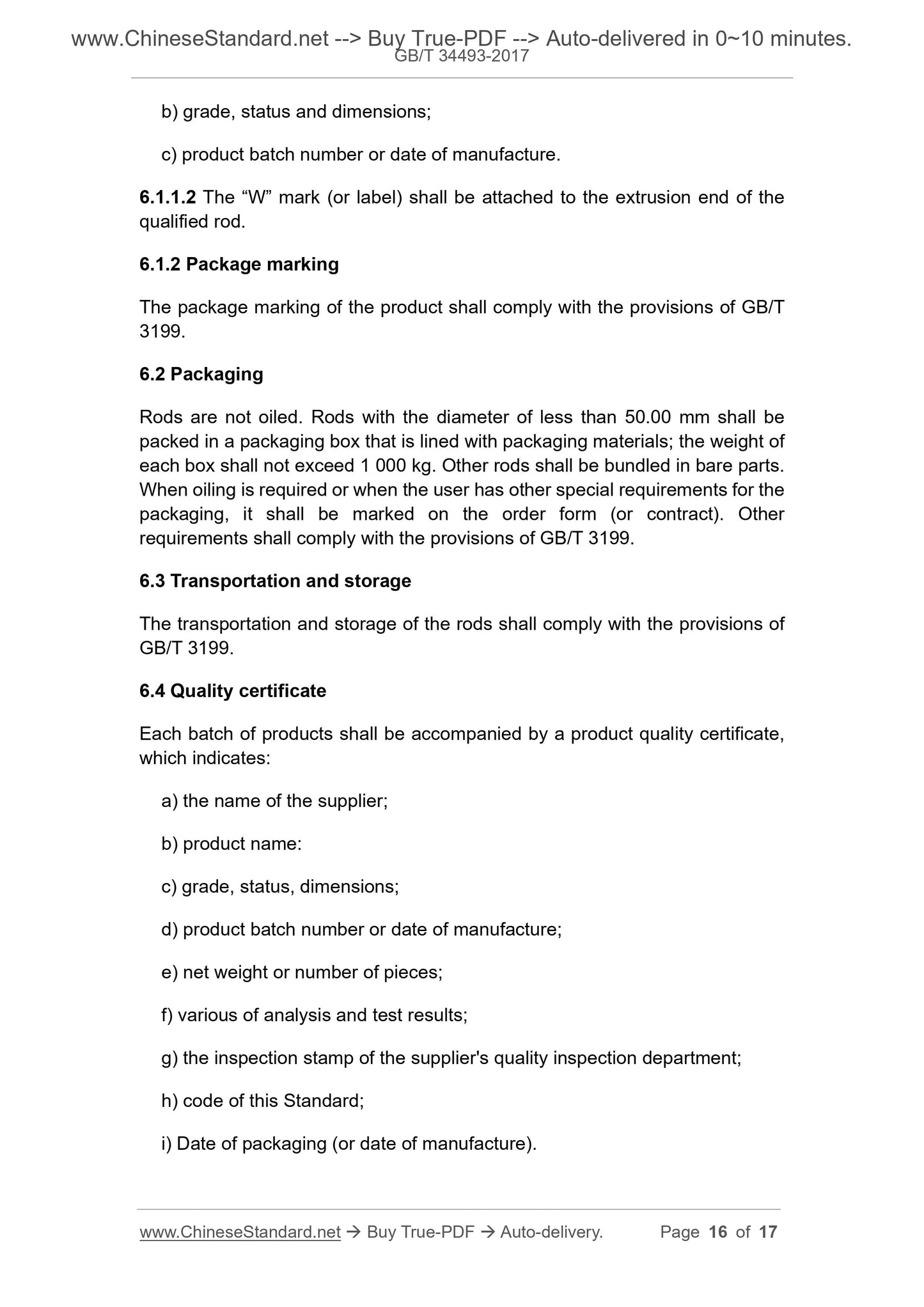

This Standard specifies the requirements, test methods, test rules and marking,packaging, transportation, storage, quality certificate and order form (or

contract) contents of aluminium alloys extruded rods for easy-cutting.

This Standard applies to aluminium alloys extruded rods for easy-cutting

(hereinafter referred to as rods).

Basic Data

| Standard ID | GB/T 34493-2017 (GB/T34493-2017) |

| Description (Translated English) | Aluminium Alloys Extruded Rods for Easy-cutting |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | H61 |

| Classification of International Standard | 77.150.10 |

| Word Count Estimation | 14,191 |

| Date of Issue | 2017-10-14 |

| Date of Implementation | 2018-05-01 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

Share