1

/

of

8

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 33610.1-2019 English PDF (GB/T33610.1-2019)

GB/T 33610.1-2019 English PDF (GB/T33610.1-2019)

Regular price

$255.00

Regular price

Sale price

$255.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 33610.1-2019: Textiles -- Determination of deodorant property -- Part 1: General principle

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 33610.1-2019 (Self-service in 1-minute)

Newer / historical versions: GB/T 33610.1-2019

Preview True-PDF

Scope

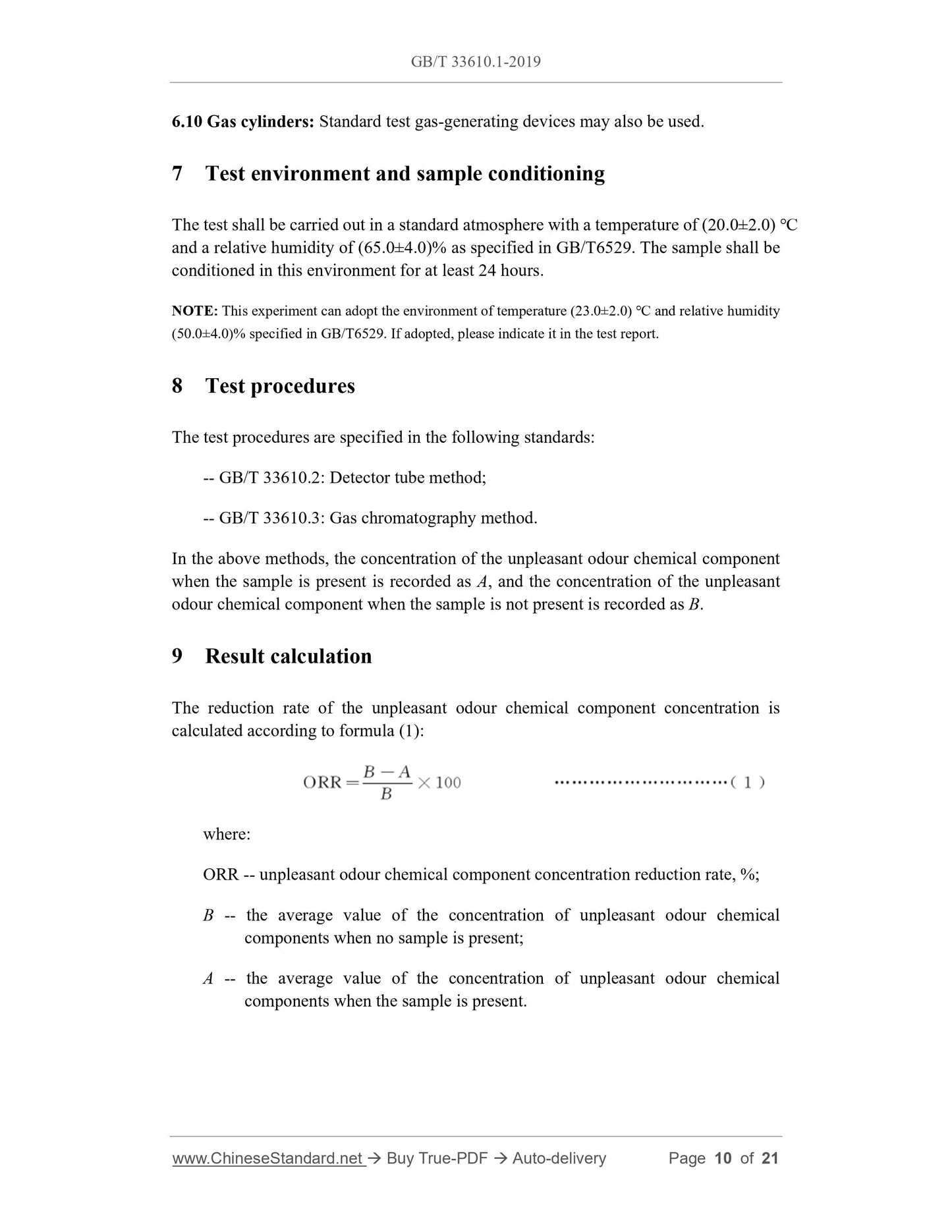

This part of GB/T 33610 specifies the general principles for the determination of thedeodorant properties of textiles.

This part applies to textile products such as woven fabrics, knitted fabrics, non-woven

fabrics, fibers and yarns, braids, strips and ropes.

Basic Data

| Standard ID | GB/T 33610.1-2019 (GB/T33610.1-2019) |

| Description (Translated English) | Textiles -- Determination of deodorant property -- Part 1: General principle |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | W04 |

| Classification of International Standard | 59.080.01 |

| Word Count Estimation | 18,114 |

| Date of Issue | 2019-12-31 |

| Date of Implementation | 2020-07-01 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share