1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 33579-2017 English PDF (GB/T33579-2017)

GB/T 33579-2017 English PDF (GB/T33579-2017)

Regular price

$560.00

Regular price

Sale price

$560.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

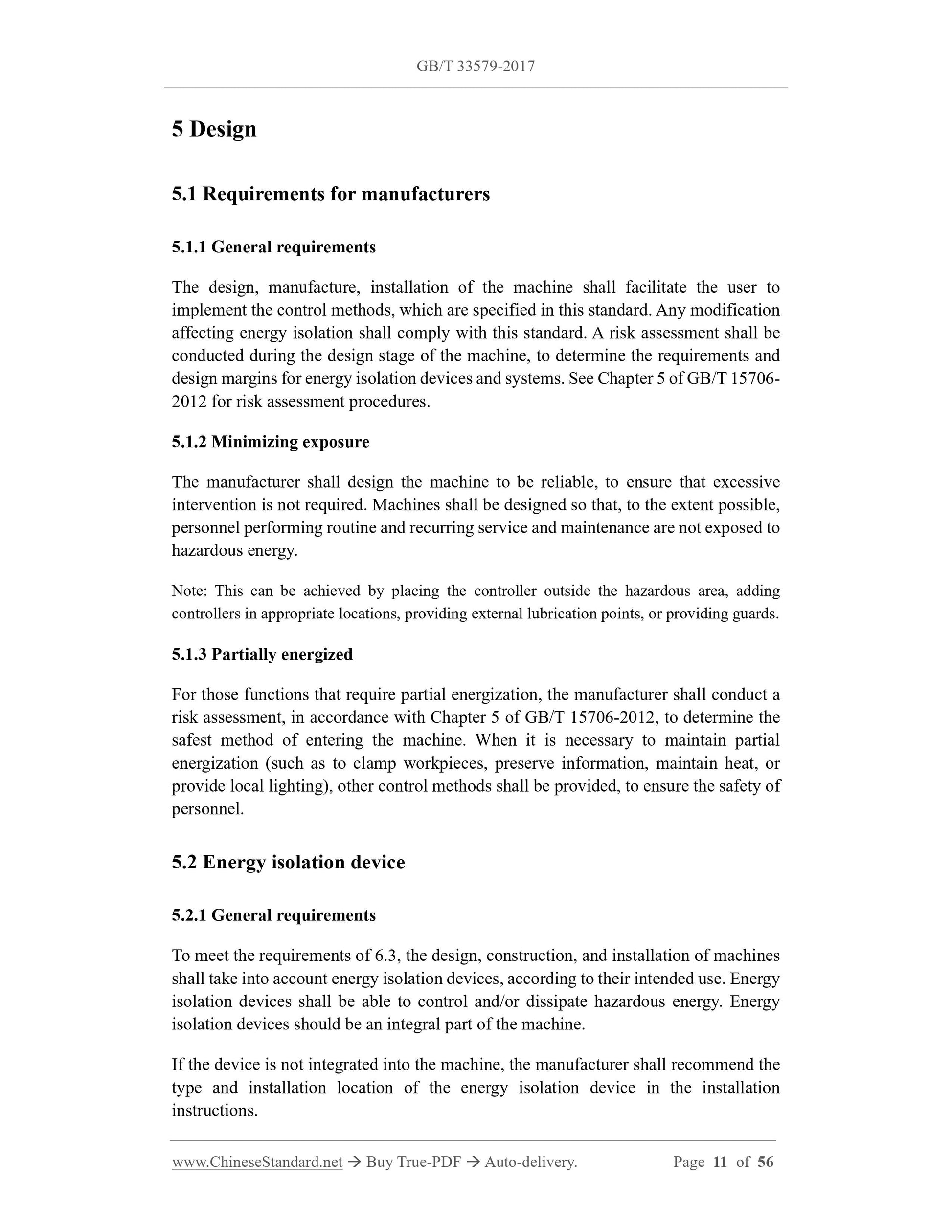

GB/T 33579-2017: Safety of machinery - Control methods of hazardous energy - Lockout/Tagout

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 33579-2017 (Self-service in 1-minute)

Newer / historical versions: GB/T 33579-2017

Preview True-PDF

Scope

This standard specifies requirements for the control of hazardous energy that may causepersonal injury.

This standard also specifies the protection steps, technology, design, methods,

performance indicators for controlling the accidental release of hazardous energy 1), so

as to avoid personal injury.

This standard applies to the design, manufacturing, installation, construction, repair,

adjustment, inspection, dredging, setting, fault finding, testing, cleaning, disassembly,

service, maintenance during the entire life cycle of the machine.

This standard does not apply to service or maintenance work on electrical equipment,

that is connected to the power supply by wires and plugs, AND where the plugging and

unplugging of the power plug is only under the personal control of the service or

maintenance personnel. In this case, unplugging the power cord may control the

possible injury, which is caused by accidentally energizing or accidentally starting the

machine.

This standard also does not apply to pressure pipeline transmission and distribution

systems involving water, steam, natural gas or petroleum products.

Basic Data

| Standard ID | GB/T 33579-2017 (GB/T33579-2017) |

| Description (Translated English) | Safety of machinery - Control methods of hazardous energy - Lockout/Tagout |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | J09 |

| Classification of International Standard | 13.110 |

| Word Count Estimation | 38,369 |

| Date of Issue | 2017-05-12 |

| Date of Implementation | 2017-12-01 |

| Quoted Standard | GB 5226.1-2008; GB/T 15706-2012; GB/T 19876 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies hazardous energy control requirements that may cause personal injury. This standard also specifies protection procedures, techniques, designs, methods, and performance indicators that control the release of hazardous energy (1), thereby avoiding injury. This standard is applicable to the design, manufacture, installation, construction, repair, adjustment, inspection, dredging, setting, fault finding, testing, cleaning, disassembly, maintenance and maintenance of the whole life cycle of the machine. This standard does not apply to the maintenance of the electrical equipment connected by the maintenance and maintenance personnel only by the connection of the electric wire and the plug and the plug of the power plug. In this case, unplugging the power plug to control accidental power failure or accidentally starting the machine may cause injury. This standard does not apply to water, steam, natural gas or petroleum products |

Share