1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 33514-2017 English PDF (GB/T33514-2017)

GB/T 33514-2017 English PDF (GB/T33514-2017)

Regular price

$120.00

Regular price

Sale price

$120.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 33514-2017: Steel cord conveyor belts -- Determination of the lateral and vertical displacement of steel cords

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 33514-2017 (Self-service in 1-minute)

Newer / historical versions: GB/T 33514-2017

Preview True-PDF

Scope

This Standard specifies the method for determining the average lateral displacementof steel cord in the steel cord conveyor belt, and the vertical displacement relative to

the average height of the rope in GB/T 28267.1 [1].

This Standard is applicable to the steel cord conveyor belts.

2 Method A. Measurement of Steel Rope Spacing and

Enhanced Belt Width

2.1 Instrument

NOTE. If there is a similar or more accurate instrument, it can also be used.

2.1.1 Band tape with scale of 1.0mm.

2.1.2 Hand-held optical magnifying glass with a scale of 0.1mm, and the magnification

is no less than 8×.

2.1.3 Dial gauge with a scale of 0.1mm.

2.1.4 The flat horizontal surface used for placing the full-width conveyor belt.

2.2 Specimen

The specimen shall be of full width and no-less-than-50mm length of the belt. The

cutting edge shall be smooth and free of dirt; the steel rope shall be clearly exposed.

If the cutting edge is not very smooth, the specimen can be prepared in a different

manner; so that ensure accurate measurement of the rope position in accordance with

this Standard.

2.3 Test Procedures

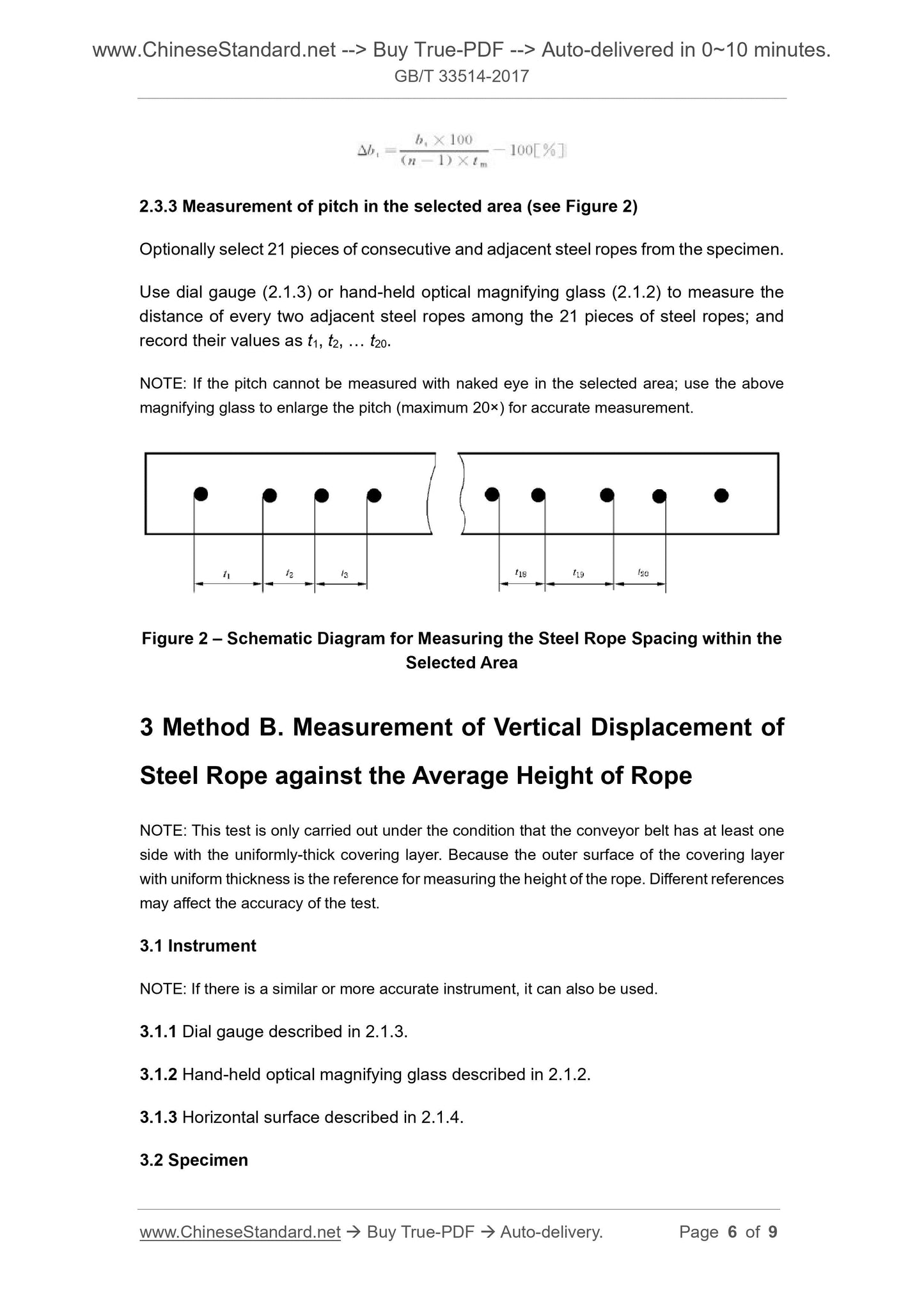

2.3.3 Measurement of pitch in the selected area (see Figure 2)

Optionally select 21 pieces of consecutive and adjacent steel ropes from the specimen.

Use dial gauge (2.1.3) or hand-held optical magnifying glass (2.1.2) to measure the

distance of every two adjacent steel ropes among the 21 pieces of steel ropes; and

record their values as t1, t2, ... t20.

NOTE. If the pitch cannot be measured with naked eye in the selected area; use the above

magnifying glass to enlarge the pitch (maximum 20×) for accurate measurement.

Figure 2 – Schematic Diagram for Measuring the Steel Rope Spacing within the

Selected Area

3 Method B. Measurement of Vertical Displacement of

Steel Rope against the Average Height of Rope

NOTE. This test is only carried out under the condition that the conveyor belt has at least one

side with the uniformly-thick covering layer. Because the outer surface of the covering layer

with uniform thickness is the reference for measuring the height of the rope. Different references

may affect the accuracy of the test.

3.1 Instrument

NOTE. If there is a similar or more accurate instrument, it can also be used.

3.1.1 Dial gauge described in 2.1.3.

3.1.2 Hand-held optical magnifying glass described in 2.1.2.

3.1.3 Horizontal surface described in 2.1.4.

3.2 Specimen

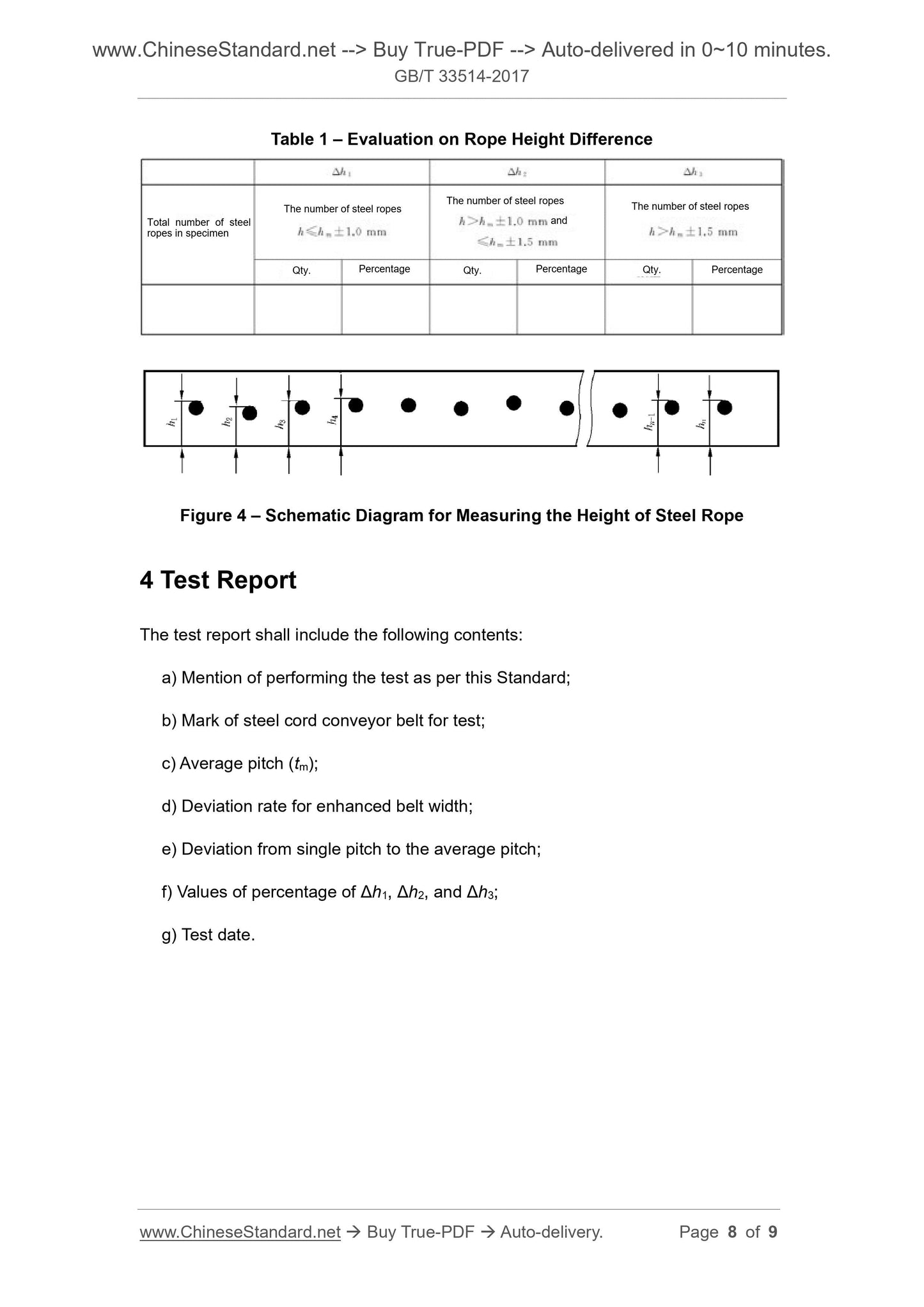

Table 1 – Evaluation on Rope Height Difference

Figure 4 – Schematic Diagram for Measuring the Height of Steel Rope

Basic Data

| Standard ID | GB/T 33514-2017 (GB/T33514-2017) |

| Description (Translated English) | Steel cord conveyor belts -- Determination of the lateral and vertical displacement of steel cords |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | G42 |

| Classification of International Standard | 53.040.20 |

| Word Count Estimation | 7,731 |

| Date of Issue | 2017-02-28 |

| Date of Implementation | 2017-09-01 |

| Regulation (derived from) | National Standard Announcement No. 4 of 2017 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the method of determining the average lateral displacement of the wire rope in the steel cord conveyor belt and the vertical displacement relative to the average height of the rope in GB/T 28267.1 ^ [1]. This standard applies to steel cord conveyor belt. |

Share