1

/

of

11

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 3323.2-2019 English PDF (GB/T3323.2-2019)

GB/T 3323.2-2019 English PDF (GB/T3323.2-2019)

Regular price

$640.00

Regular price

Sale price

$640.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

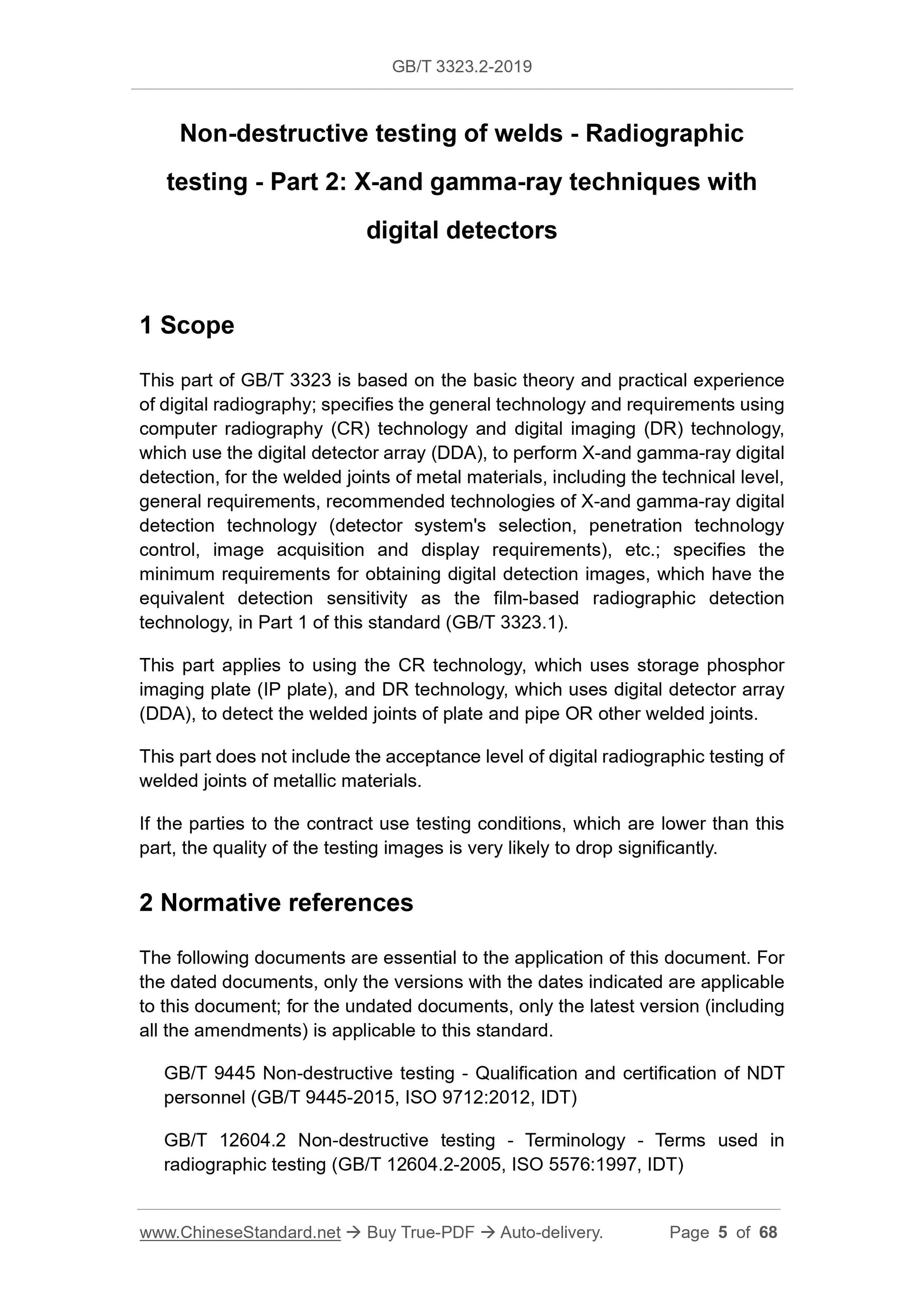

GB/T 3323.2-2019: Non-destructive testing of welds -- Radiographic testing -- Part 2: X-and gamma-ray techniques with digital detectors

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 3323.2-2019 (Self-service in 1-minute)

Newer / historical versions: GB/T 3323.2-2019

Preview True-PDF

Scope

This part of GB/T 3323 is based on the basic theory and practical experienceof digital radiography; specifies the general technology and requirements using

computer radiography (CR) technology and digital imaging (DR) technology,

which use the digital detector array (DDA), to perform X-and gamma-ray digital

detection, for the welded joints of metal materials, including the technical level,

general requirements, recommended technologies of X-and gamma-ray digital

detection technology (detector system's selection, penetration technology

control, image acquisition and display requirements), etc.;

Basic Data

| Standard ID | GB/T 3323.2-2019 (GB/T3323.2-2019) |

| Description (Translated English) | Non-destructive testing of welds -- Radiographic testing -- Part 2: X-and gamma-ray techniques with digital detectors |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | J33 |

| Classification of International Standard | 25.160.40 |

| Word Count Estimation | 50,590 |

| Date of Issue | 2019-08-30 |

| Date of Implementation | 2020-03-01 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share