1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 32685-2016 English PDF (GB/T32685-2016)

GB/T 32685-2016 English PDF (GB/T32685-2016)

Regular price

$110.00

Regular price

Sale price

$110.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 32685-2016: Purified terephthalic acid (PTA) for industrial use

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 32685-2016 (Self-service in 1-minute)

Newer / historical versions: GB/T 32685-2016

Preview True-PDF

Scope

This Standard specifies the technical requirements, test methods, inspection rules,packaging, marking, transportation, storage and safety requirements for purified

terephthalic acid (PTA) for industrial use.

This Standard applies to purified terephthalic acid (PTA) for industrial use, which is

obtained from petroleum p-xylene through oxidation and refining. This product is

mainly used as a raw material for the production of polyester chips, long and short

polyester fibers and chemical products.

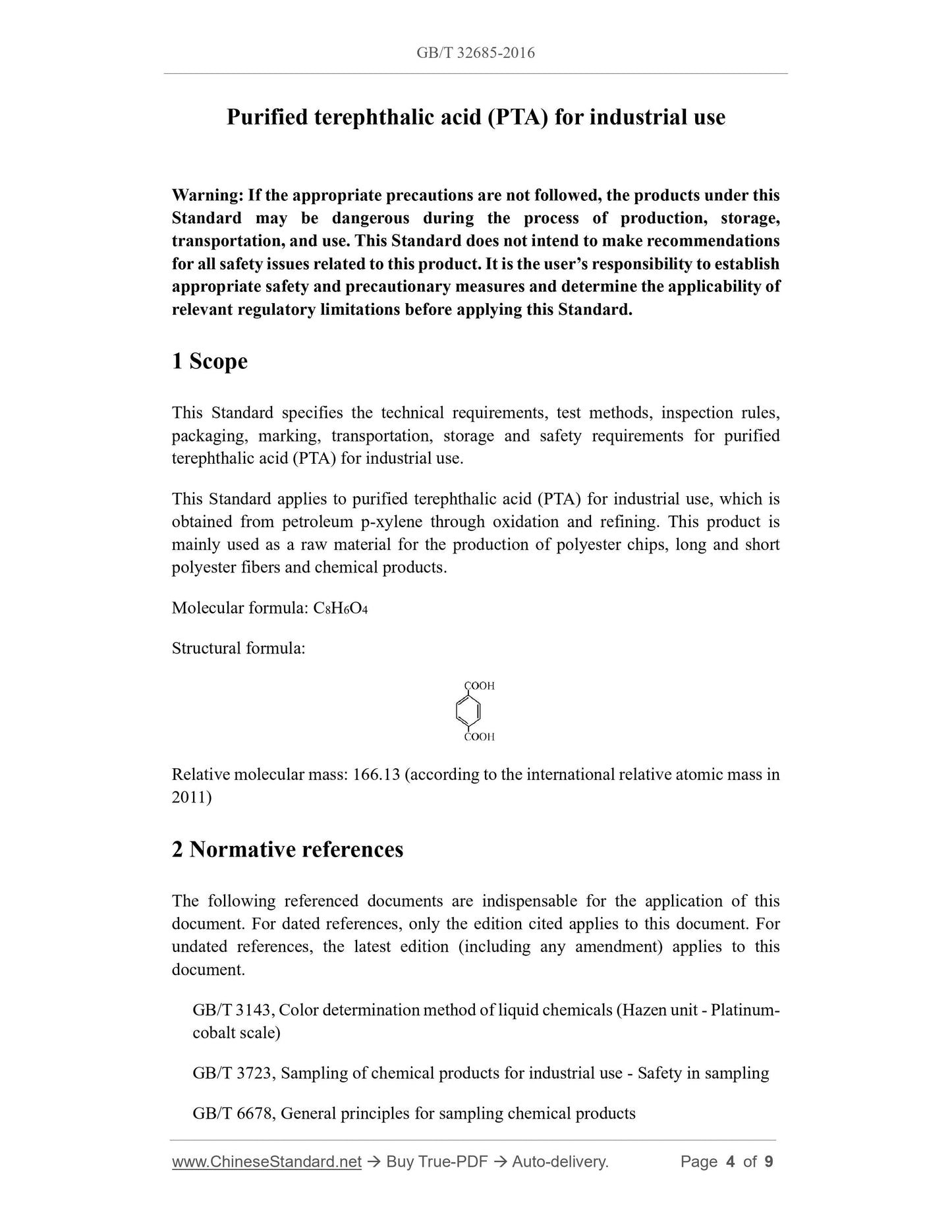

Molecular formula: C8H6O4

Structural formula:

Relative molecular mass: 166.13 (according to the international relative atomic mass in

2011)

Basic Data

| Standard ID | GB/T 32685-2016 (GB/T32685-2016) |

| Description (Translated English) | Purified terephthalic acid (PTA) for industrial use |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | G16 |

| Classification of International Standard | 71.080.40 |

| Word Count Estimation | 6,699 |

| Date of Issue | 2016-06-14 |

| Date of Implementation | 2017-01-01 |

| Quoted Standard | GB/T 3143; GB/T 3723; GB/T 6678; GB/T 6679; GB/T 7531; GB/T 8170; GB/T 17521; GB/T 30921.1; GB/T 30921.2; GB/T 30921.3; GB/T 30921.4; GB/T 30921.5; GB/T 30921.6; GB/T 30921.7 |

| Regulation (derived from) | National Standard Announcement No. 8 of 2016 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the technical requirements, test methods, inspection rules, packaging, marking, transportation, storage and safety requirements for industrial refined terephthalic acid (PTA). This standard applies to petroleum paraxylene as raw material, the oxidation, refined industrial system of purified terephthalic acid (PTA). The product is mainly used for the production of polyester chips, the length of polyester fiber and chemical raw materials. |

Share