1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 324-2008 English PDF (GB/T324-2008)

GB/T 324-2008 English PDF (GB/T324-2008)

Regular price

$70.00

Regular price

Sale price

$70.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

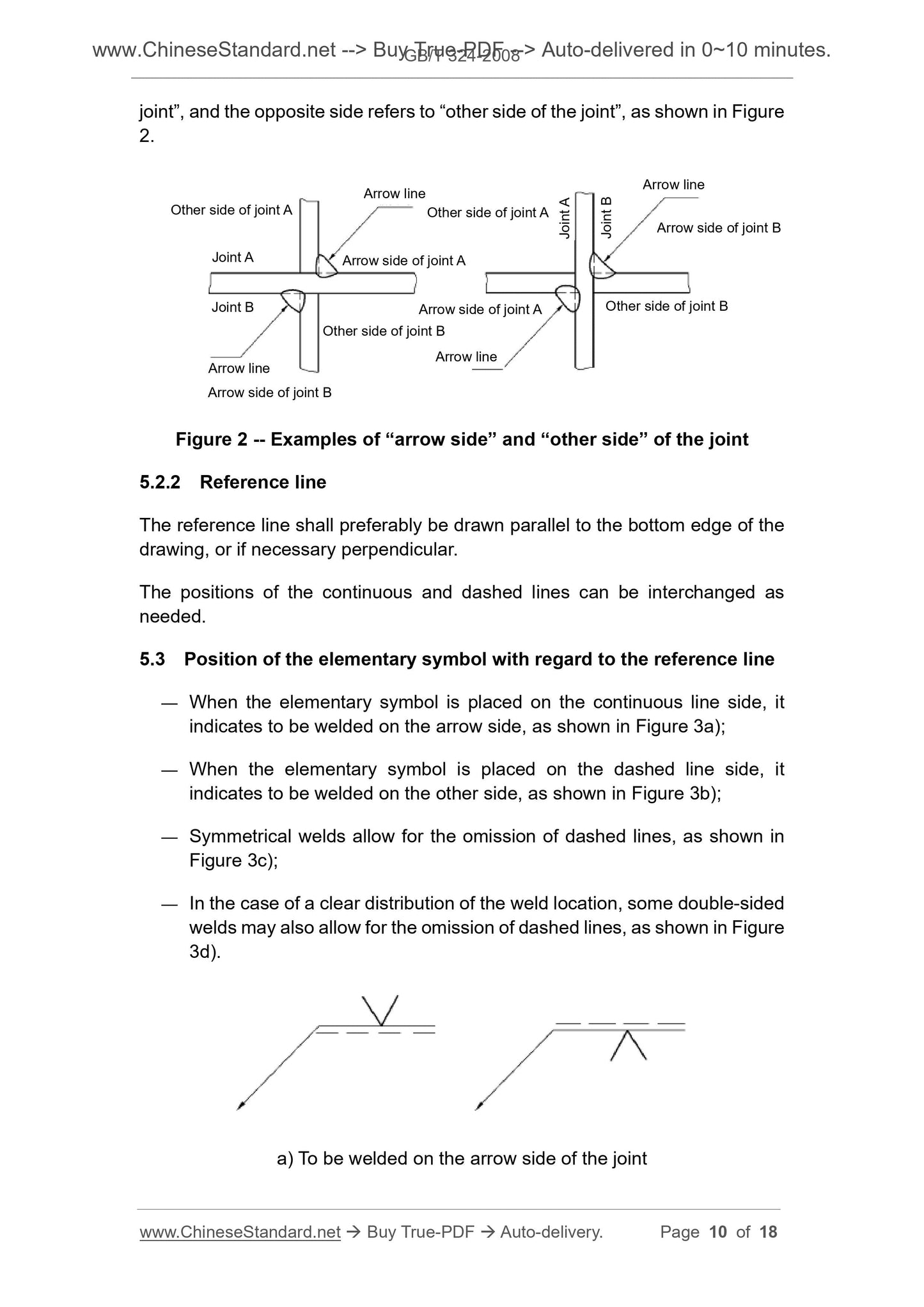

GB/T 324-2008: Weld symbolic representation on drawings

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 324-2008 (Self-service in 1-minute)

Newer / historical versions: GB/T 324-2008

Preview True-PDF

Scope

This Standard specifies the rules for weld symbolic representation.This Standard applies to the symbolic labeling of welded joints.

Basic Data

| Standard ID | GB/T 324-2008 (GB/T324-2008) |

| Description (Translated English) | Weld symbolic representation on drawings |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | J04;J33 |

| Classification of International Standard | 25.160.01 |

| Word Count Estimation | 15,122 |

| Date of Issue | 2008-06-26 |

| Date of Implementation | 2009-01-01 |

| Older Standard (superseded by this standard) | GB/T 324-1988 |

| Quoted Standard | GB/T 5185; GB/T 12212; GB/T 16672; GB/T 19418 |

| Adopted Standard | ISO 2553-1992, MOD |

| Regulation (derived from) | National Standard Approval Announcement 2008 No.11 (Total No.124) |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the representation rules weld symbols. This standard applies to balloons welded joints. |

Share