1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 31467.2-2015 English PDF (GB/T31467.2-2015)

GB/T 31467.2-2015 English PDF (GB/T31467.2-2015)

Regular price

$85.00

Regular price

Sale price

$85.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

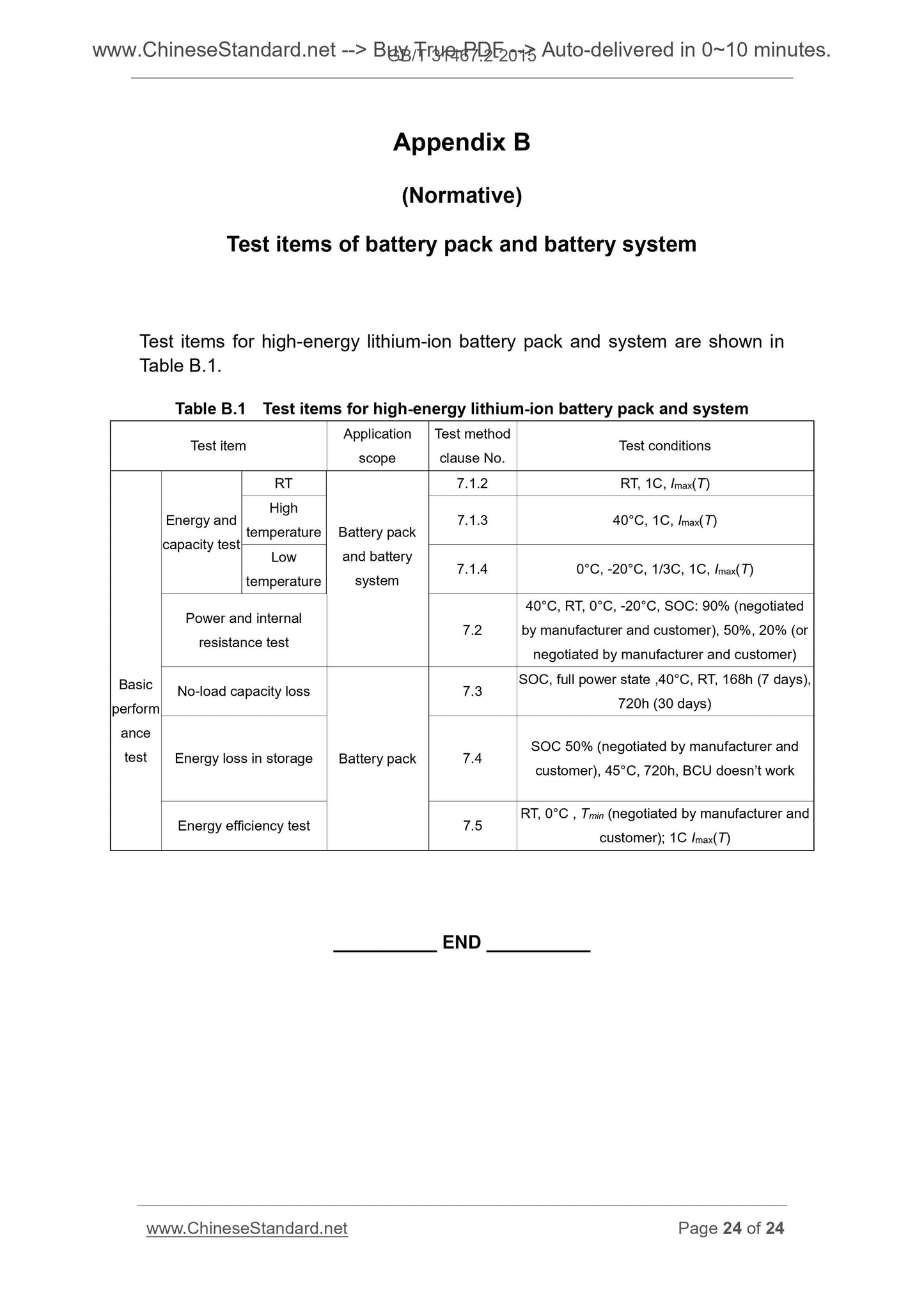

GB/T 31467.2-2015: [Replaced by GB/T 31467-2023] Lithium-ion traction battery pack and system for electric vehicles -- Part 2: Test specification for high energy applications

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 31467.2-2015 (Self-service in 1-minute)

Newer / historical versions: GB/T 31467.2-2015

Preview True-PDF

Scope

This Part of GB/T 31467 specifies test procedures for lithium-ion battery packsand systems specially developed for electric vehicles.

This Part applies to lithium-ion traction battery pack and system that is loaded

on electric vehicles and for the purpose of high energy applications. Ni-MH

traction battery packs and systems of high energy applications may refer to this

Part.

Basic Data

| Standard ID | GB/T 31467.2-2015 (GB/T31467.2-2015) |

| Description (Translated English) | [Replaced by GB/T 31467-2023] Lithium-ion traction battery pack and system for electric vehicles -- Part 2: Test specification for high energy applications |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | T47 |

| Classification of International Standard | 43.080 |

| Word Count Estimation | 20,261 |

| Date of Issue | 2015-05-15 |

| Date of Implementation | 2015-05-15 |

| Quoted Standard | GB/T 19596 |

| Adopted Standard | ISO 12405-2-2012, NEQ |

| Regulation (derived from) | National Standard Announcement 2015 No. 15 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the test methods for electric vehicles high-energy lithium-ion battery pack and electric properties of the system. This standard applies to the load on the electric vehicle, mainly for the purpose of application of high-energy lithium-ion battery pack and battery systems, in order to apply for the purpose of high-energy nickel-hydrogen battery packs and systems can be implemented by reference. |

Share