1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 3139-2005 English PDF (GB/T3139-2005)

GB/T 3139-2005 English PDF (GB/T3139-2005)

Regular price

$115.00

Regular price

Sale price

$115.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 3139-2005: Fiber-reinforced plastics composites -- Determination of thermal conductivity

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 3139-2005 (Self-service in 1-minute)

Newer / historical versions: GB/T 3139-2005

Preview True-PDF

Scope

This standard specifies the test principles, specimens, test instruments, testconditions, test procedures, calculation results and test reports for determining

the thermal conductivity of fiber-reinforced plastics by the guard hot plate

method.

This standard applies to the determination of the thermal conductivity of fiber-

reinforced plastics.

Basic Data

| Standard ID | GB/T 3139-2005 (GB/T3139-2005) |

| Description (Translated English) | Fiber-reinforced plastics composites. Determination of thermal conductivity |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | Q23 |

| Classification of International Standard | 83.120 |

| Word Count Estimation | 6,651 |

| Date of Issue | 2005-05-18 |

| Date of Implementation | 2005-12-01 |

| Older Standard (superseded by this standard) | GB/T 3139-1982 |

| Regulation (derived from) | Announcement of Newly Approved National Standards No. 8 of 2005 (No. 82 overall) |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People Republic of China, China National Standardization Administration Committee |

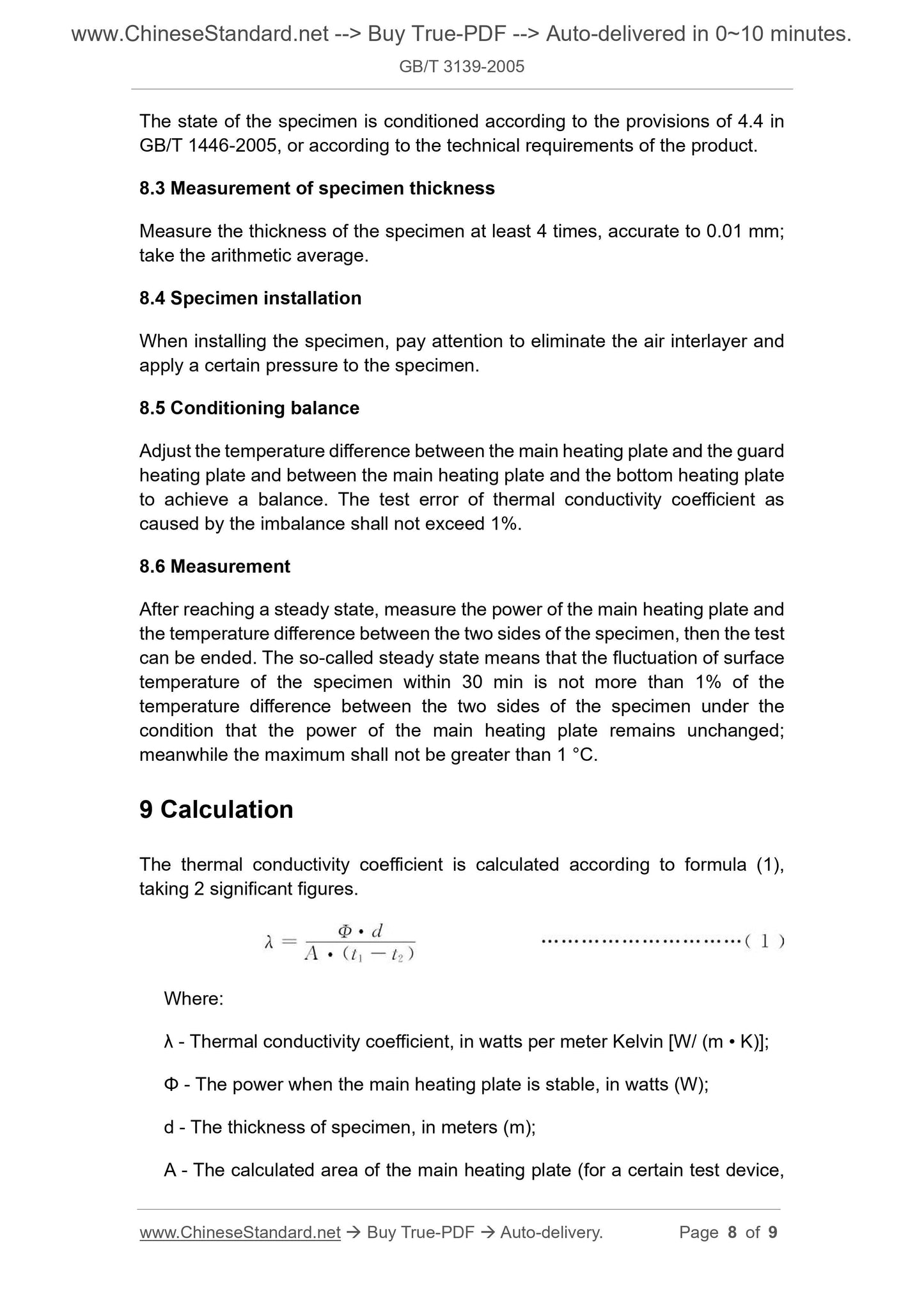

| Summary | This standard specifies: Guarded hot plate method for the determination of fiber reinforced plastic thermal conductivity test principle, sample, test equipment, test conditions, test procedures, calculations and test reports. This standard applies to: Determination of fiber-reinforced plastics Thermal conductivity. |

Share