1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 3093-2021 English PDF (GB/T3093-2021)

GB/T 3093-2021 English PDF (GB/T3093-2021)

Regular price

$215.00

Regular price

Sale price

$215.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

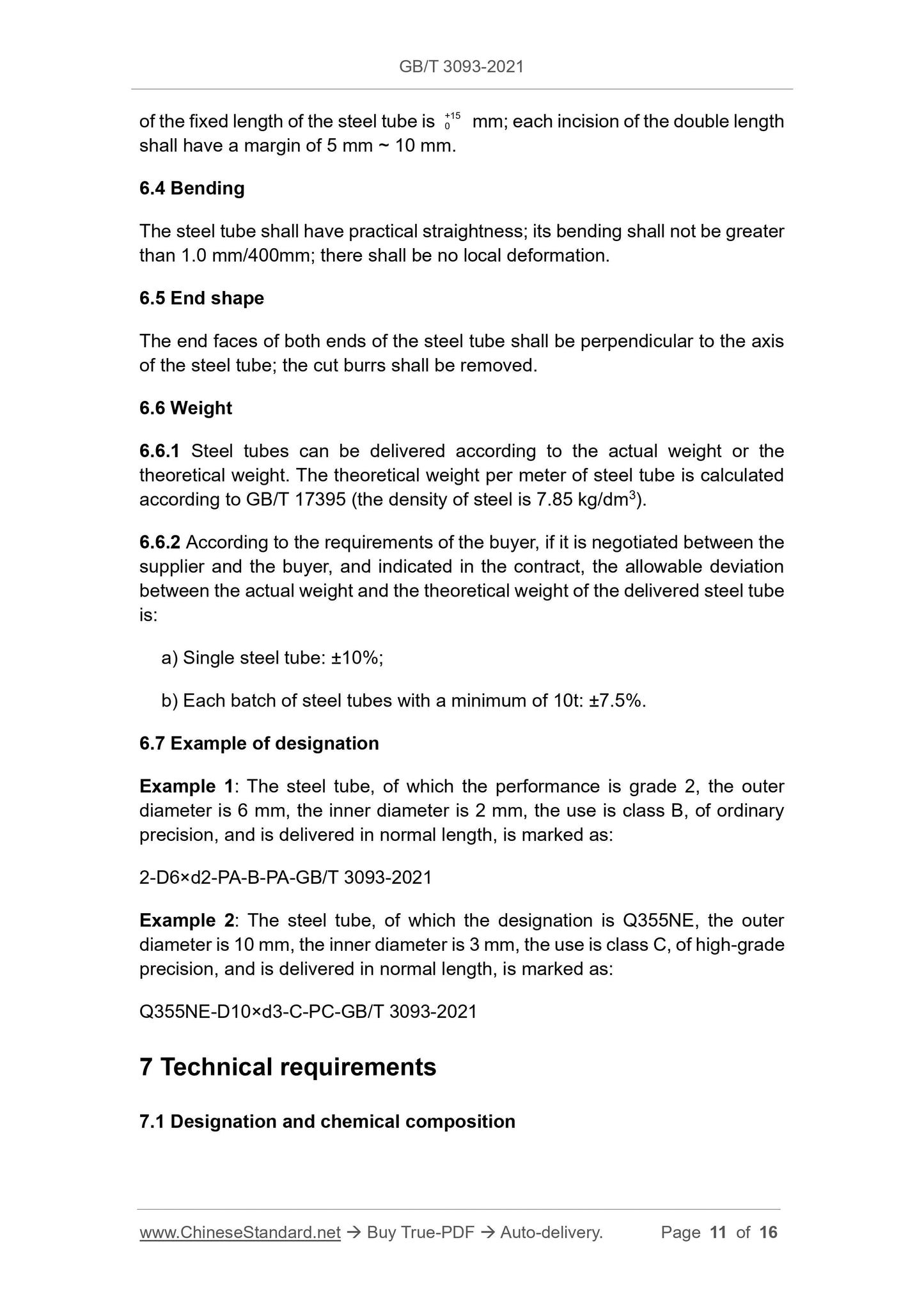

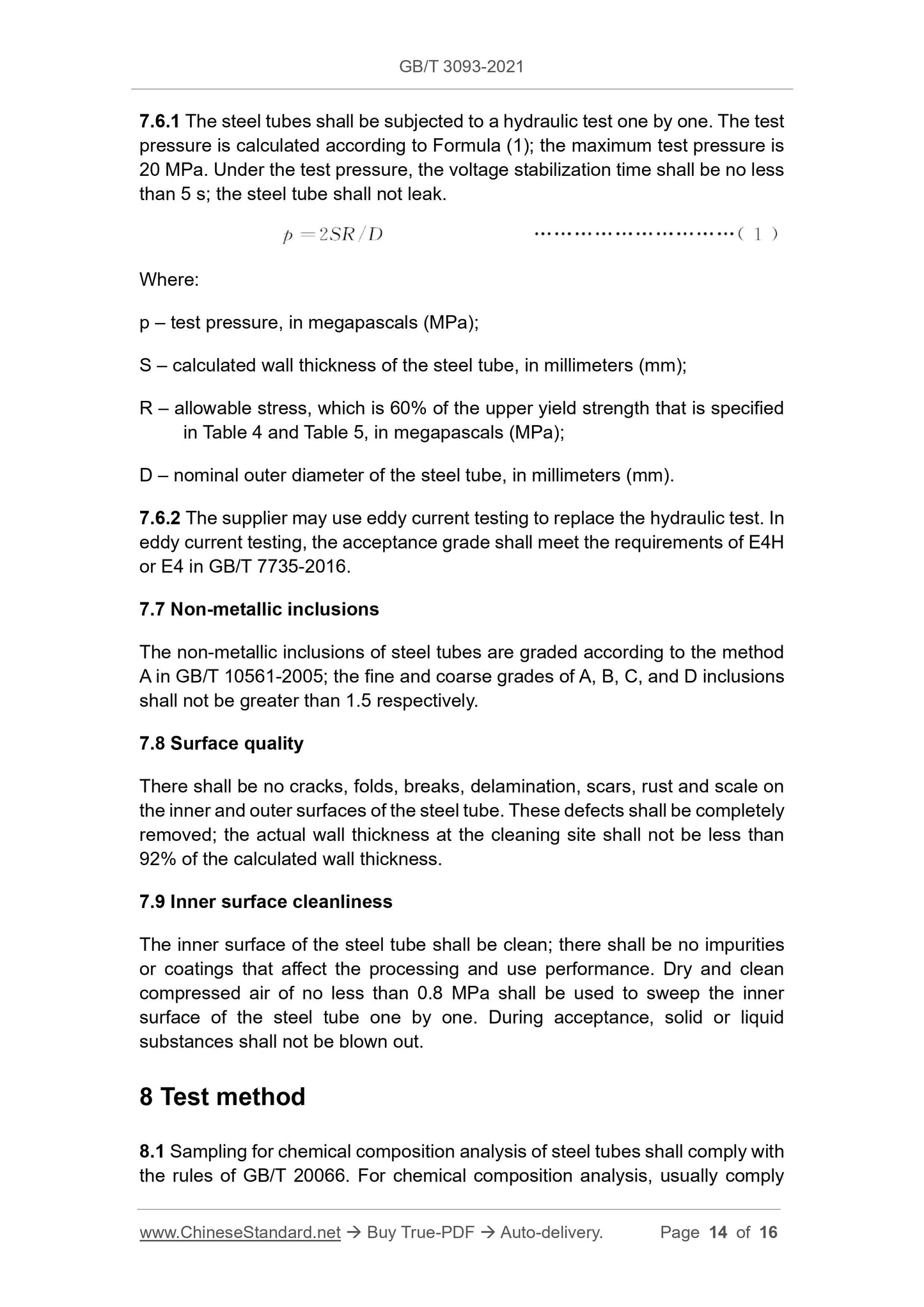

GB/T 3093-2021: High-pressure seamless steel tubes for diesel engine

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 3093-2021 (Self-service in 1-minute)

Newer / historical versions: GB/T 3093-2021

Preview True-PDF

Scope

This document specifies the classification and code, order content, size, shape,weight and allowable deviation, technical requirements, test methods,

inspection rules, packaging, marking and quality certificates of high-pressure

seamless steel tubes for diesel engine.

This document applies to cold-drawn (rolled) seamless steel tubes (hereinafter

referred to as "steel tubes") which are used for the manufacture of high-

pressure oil tubes of the diesel engine injection system.

Basic Data

| Standard ID | GB/T 3093-2021 (GB/T3093-2021) |

| Description (Translated English) | High-pressure seamless steel tubes for diesel engine |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | H48 |

| Word Count Estimation | 11,133 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share