1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 30127-2013 English PDF (GB/T30127-2013)

GB/T 30127-2013 English PDF (GB/T30127-2013)

Regular price

$145.00

Regular price

Sale price

$145.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

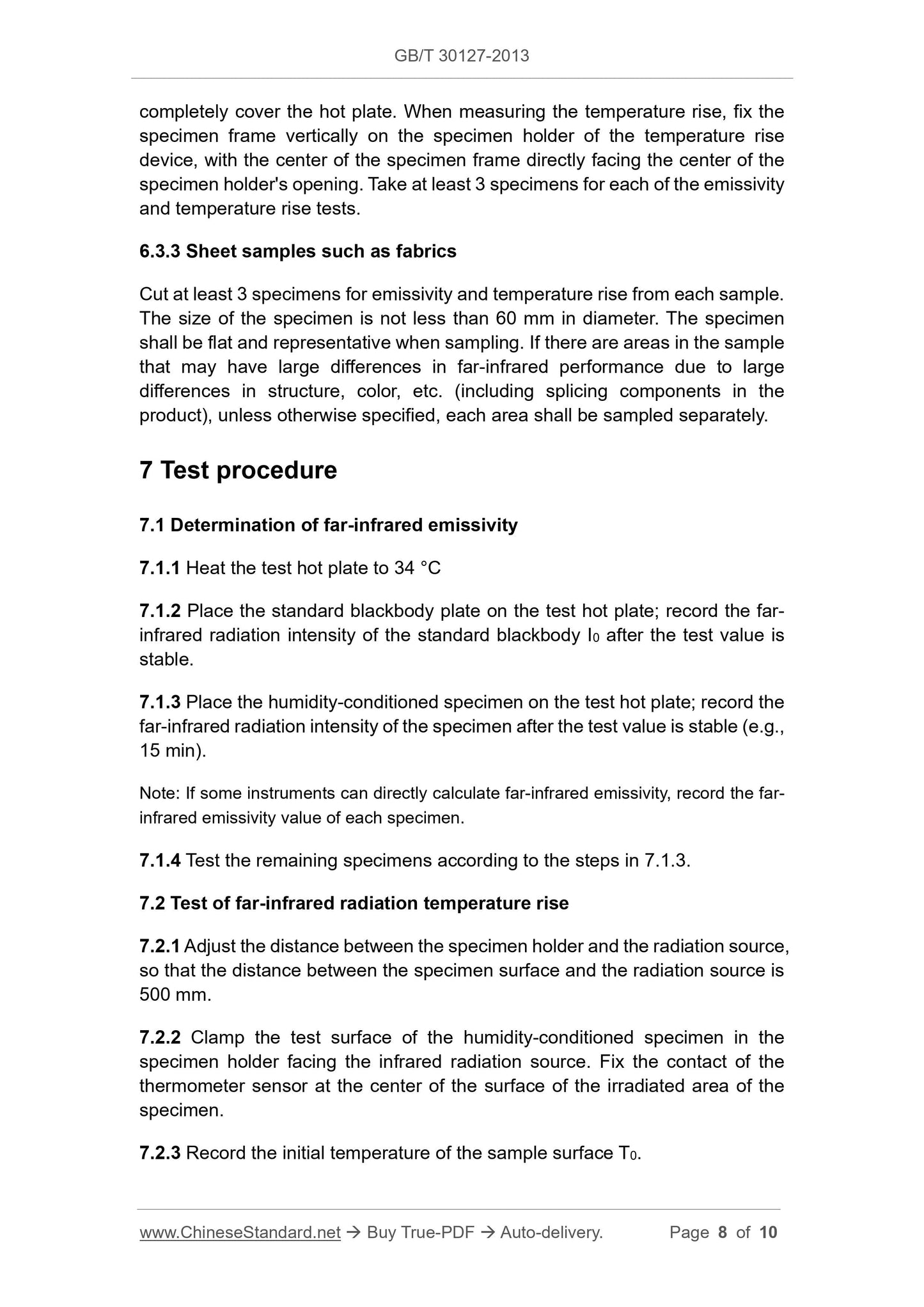

GB/T 30127-2013: Textiles - Testing and evaluation for far infrared radiation properties

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 30127-2013 (Self-service in 1-minute)

Newer / historical versions: GB/T 30127-2013

Preview True-PDF

Scope

This standard specifies the method for measuring the far-infrared radiationproperty of textiles by the far-infrared emissivity and temperature rise test; gives

the evaluation of the far-infrared radiation property.

This standard applies to all types of textile products, including fibers, yarns,

fabrics, non-woven fabrics and their products. Other materials can refer to it.

This standard does not involve the evaluation of medical effects.

Basic Data

| Standard ID | GB/T 30127-2013 (GB/T30127-2013) |

| Description (Translated English) | Textiles - Testing and evaluation for far infrared radiation properties |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | W04 |

| Classification of International Standard | 59.080.01 |

| Word Count Estimation | 8,819 |

| Quoted Standard | GB/T 6529; GB/T 8629-2001 |

| Regulation (derived from) | National Standards Bulletin No. 25 of 2013 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the use of far-infrared emissivity and temperature rise test measures the performance of far infrared textiles methods, and gives the evaluation of the performance of the far-infrared. This standard applies to all types of textile |

Share