1

/

of

8

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 3001-2007 English PDF (GB/T3001-2007)

GB/T 3001-2007 English PDF (GB/T3001-2007)

Regular price

$90.00

Regular price

Sale price

$90.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 3001-2007: Refractory products -- Determination of modulus of rupture at ambient temperature

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 3001-2007 (Self-service in 1-minute)

Newer / historical versions: GB/T 3001-2007

Preview True-PDF

Scope

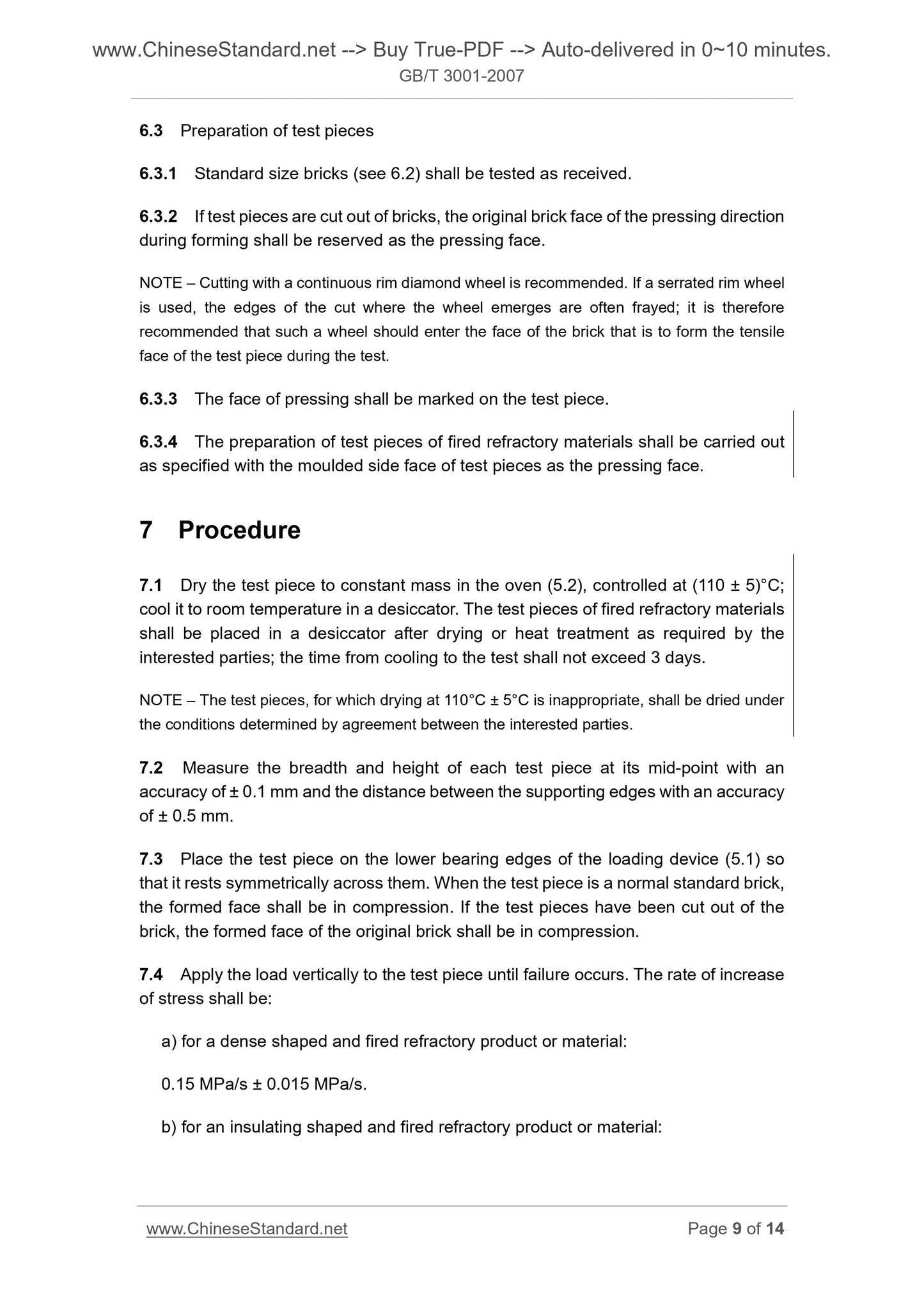

This Standard specifies a method for the determination of the modulus of rupture ofrefractory products at ambient temperature, under conditions of a constant rate of

increase of stress.

The method relates primarily to shaped and fired refractories. If it is to be applied to

chemically bonded or tar-bonded bricks, they will usually require some form of

preliminary heat treatment. This preliminary treatment, the details of which are outside

the scope of this Standard, is a matter of agreement between the interested parties

and is described in the test report.

Basic Data

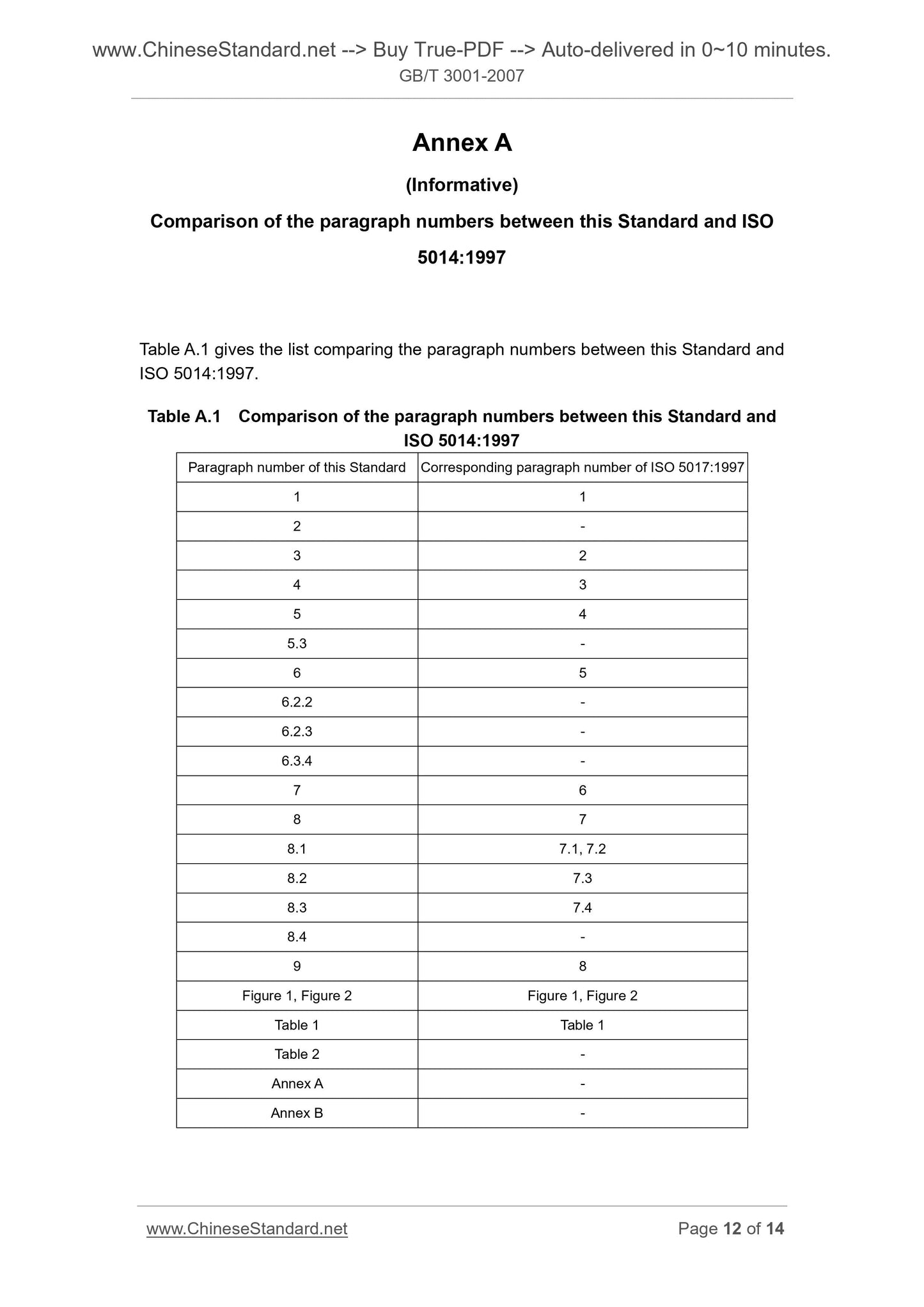

| Standard ID | GB/T 3001-2007 (GB/T3001-2007) |

| Description (Translated English) | Refractory products -- Determination of modulus of rupture at ambient temperature |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | Q40 |

| Classification of International Standard | 81.080 |

| Word Count Estimation | 9,982 |

| Date of Issue | 2007-12-14 |

| Date of Implementation | 2008-06-01 |

| Older Standard (superseded by this standard) | GB/T 3001-2000 |

| Quoted Standard | GB/T 8170; GB/T 10325 |

| Adopted Standard | ISO 5014-1997, MOD |

| Regulation (derived from) | National Standard Approval Announcement 2007 No.13 (Total No.113) |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the rate at room temperature at a constant applied stress test methods-Determination of flexural strength of refractories. This method is applicable to amorphous and monolithic refractories. If for chemical bonding or binding bricks tar, these products are to some form of pre-heat treatment. Specific provisions of this pre-heat treatment is beyond the scope of this standard, subject to the agreement the parties concerned, and noted in the test report. |

Share