1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 29658-2013 English PDF (GB/T29658-2013)

GB/T 29658-2013 English PDF (GB/T29658-2013)

Regular price

$120.00

Regular price

Sale price

$120.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

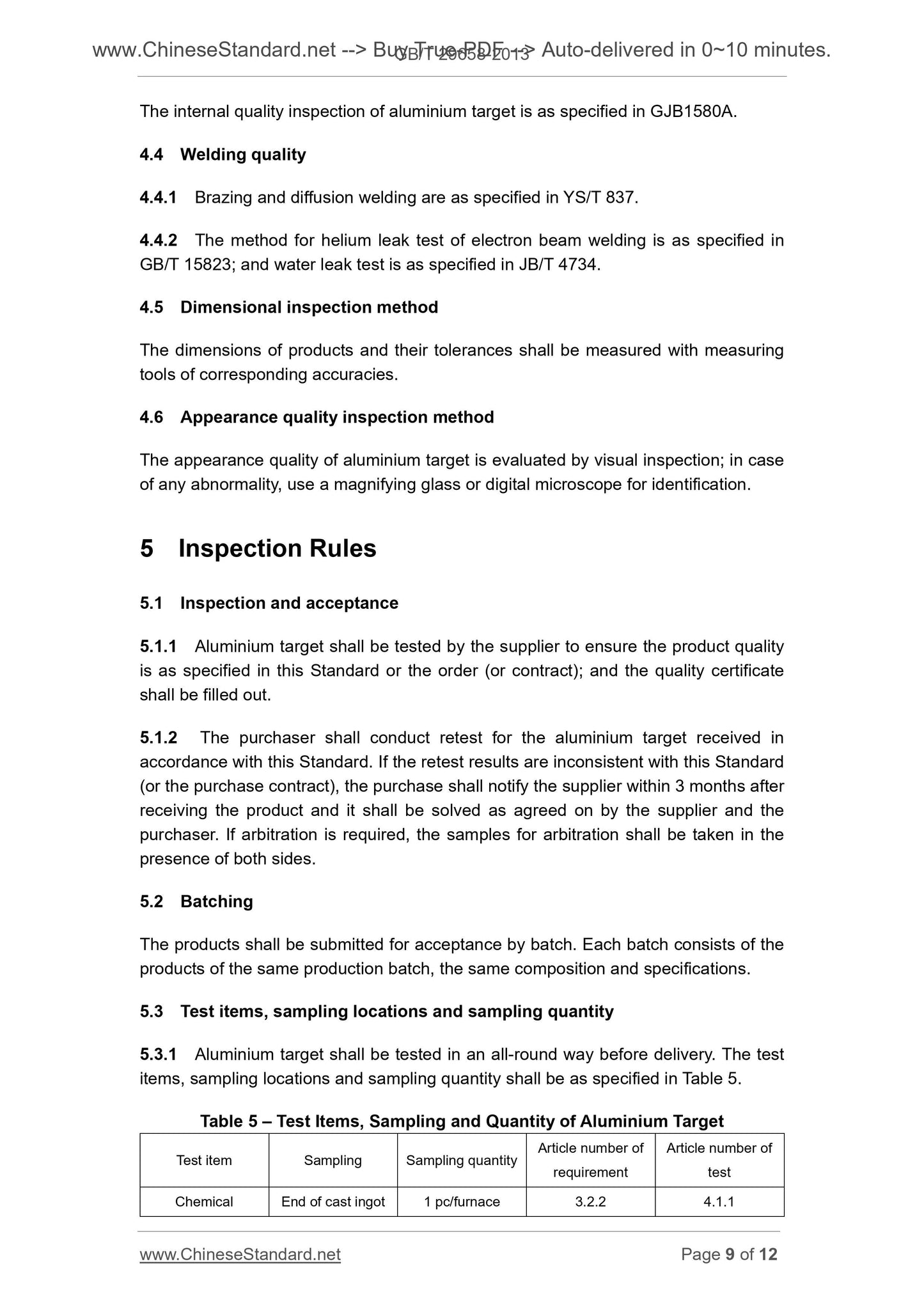

GB/T 29658-2013: High-purity Sputtering Aluminium and Aluminium Alloy Target Used in Electronic Film

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 29658-2013 (Self-service in 1-minute)

Newer / historical versions: GB/T 29658-2013

Preview True-PDF

Scope

This Standard specifies the requirements, test methods, inspection rules and marking,packaging, transportation and storage and ordering (or contracting) content of high-

purity aluminium and aluminium alloy target used in electronic film.

This Standard applies to all kinds of high-purity aluminium and aluminium alloy

sputtering target materials (hereinafter referred to as aluminium target).

Basic Data

| Standard ID | GB/T 29658-2013 (GB/T29658-2013) |

| Description (Translated English) | High-purity Sputtering Aluminium and Aluminium Alloy Target Used in Electronic Film |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | H61 |

| Classification of International Standard | 77.120.10 |

| Word Count Estimation | 10,170 |

| Quoted Standard | GB/T 1804; GB/T 6394; GB/T 14265; GB/T 15823; GB/T 20975.25; GJB 1580A; JB/T 4734; YS/T 837; YS/T 871 |

| Regulation (derived from) | National Standards Bulletin 2013 No. 17 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies: Preparation of electronic film with high purity aluminum and aluminum alloy target requirements, test methods, inspection rules and signs, packaging, transportation, storage, purchase order (or contract) content. This standard app |

Share