1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 28909-2012 English PDF (GB/T28909-2012)

GB/T 28909-2012 English PDF (GB/T28909-2012)

Regular price

$70.00

Regular price

Sale price

$70.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 28909-2012: Extra-high strength structural steel plates in the heat-treatment condition

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 28909-2012 (Self-service in 1-minute)

Newer / historical versions: GB/T 28909-2012

Preview True-PDF

Scope

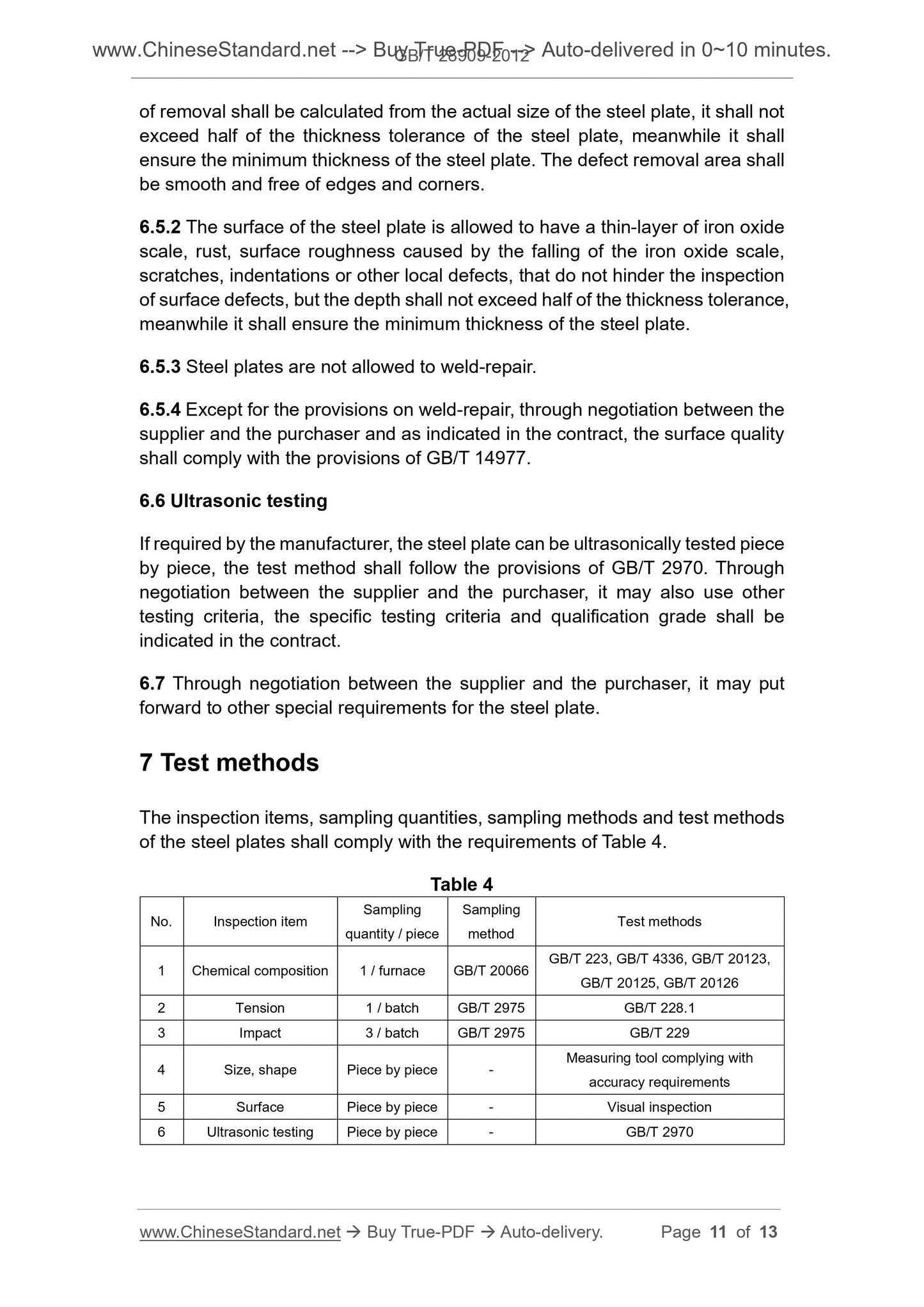

This standard specifies the ordering content, designation indication method,size, shape, weight and allowable deviation, technical requirements, test

methods, inspection rules, packaging, marking and quality certificate of extra-

high strength structural steel plates in the heat-treatment condition.

This standard is applicable to steel plates with a thickness of not more than 50

mm for construction machinery such as mines, buildings and agriculture.

Basic Data

| Standard ID | GB/T 28909-2012 (GB/T28909-2012) |

| Description (Translated English) | Extra-high strength structural steel plates in the heat-treatment condition |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | H46 |

| Classification of International Standard | 77.140.50 |

| Word Count Estimation | 9,939 |

| Quoted Standard | GB/T 222; GB/T 223.3; GB/T 223.9; GB/T 223.11; GB/T 223.12; GB/T 223.13; GB/T 223.14; GB/T 223.17; GB/T 223.23; GB/T 223.26; GB/T 223.54; GB/T 223.58; GB/T 223.59; GB/T 223.60; GB/T 223.61; GB/T 223.62; GB/T 223.63; GB/T 223.64; GB/T 223.67; GB/T 223.68; |

| Regulation (derived from) | National Standards Bulletin 2012 No. 28 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the ultra-high -strength structural steel with heat treatment order contents, brand representation, size, shape, weight and tolerances, technical requirements, test methods, inspection rules, packaging, marking and quality certific |

Share