1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 28267.4-2015 English PDF (GB/T28267.4-2015)

GB/T 28267.4-2015 English PDF (GB/T28267.4-2015)

Regular price

$90.00

Regular price

Sale price

$90.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

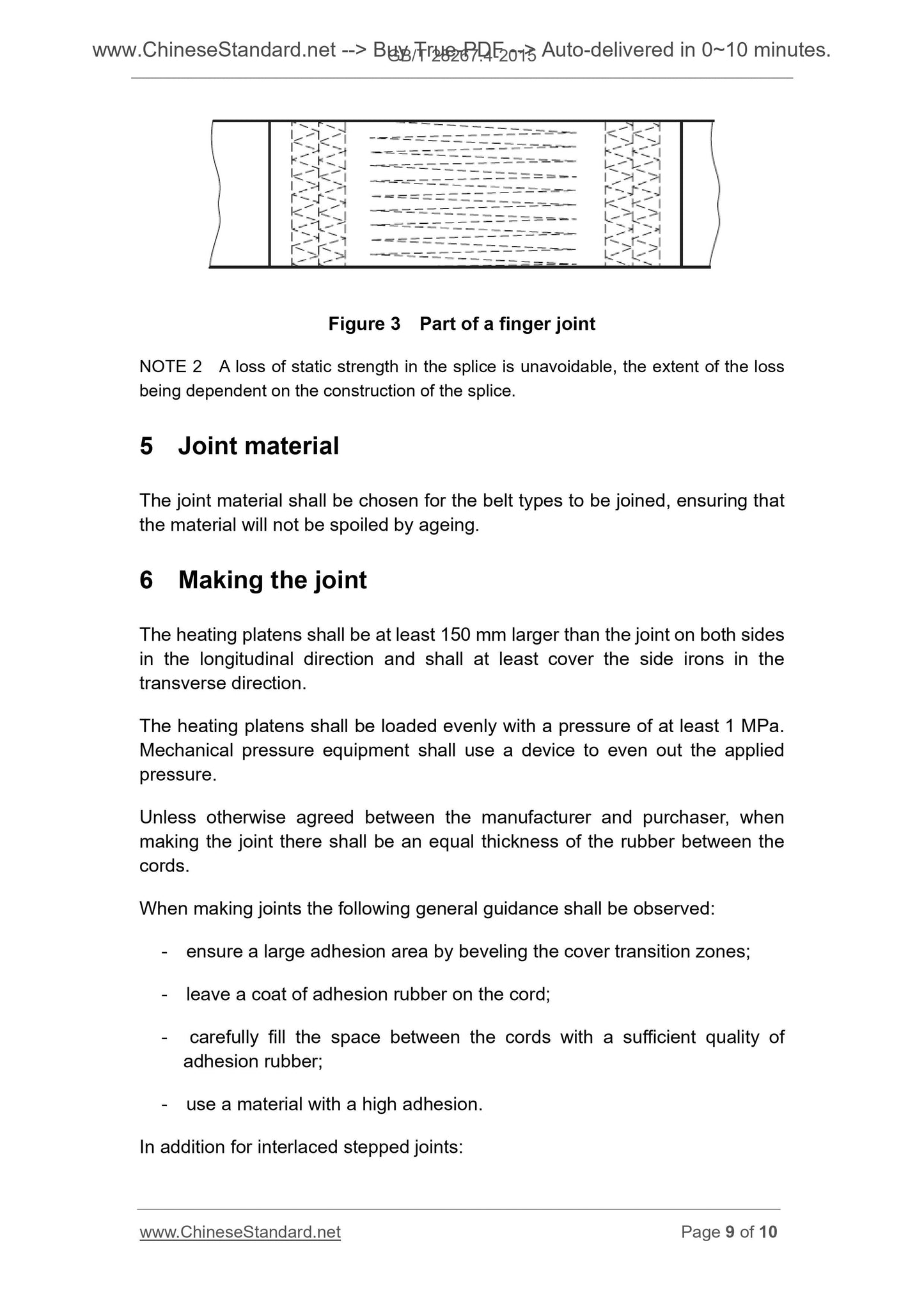

GB/T 28267.4-2015: Steel cord conveyor belts -- Part 4: Vulcanized belt joints

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 28267.4-2015 (Self-service in 1-minute)

Newer / historical versions: GB/T 28267.4-2015

Preview True-PDF

Scope

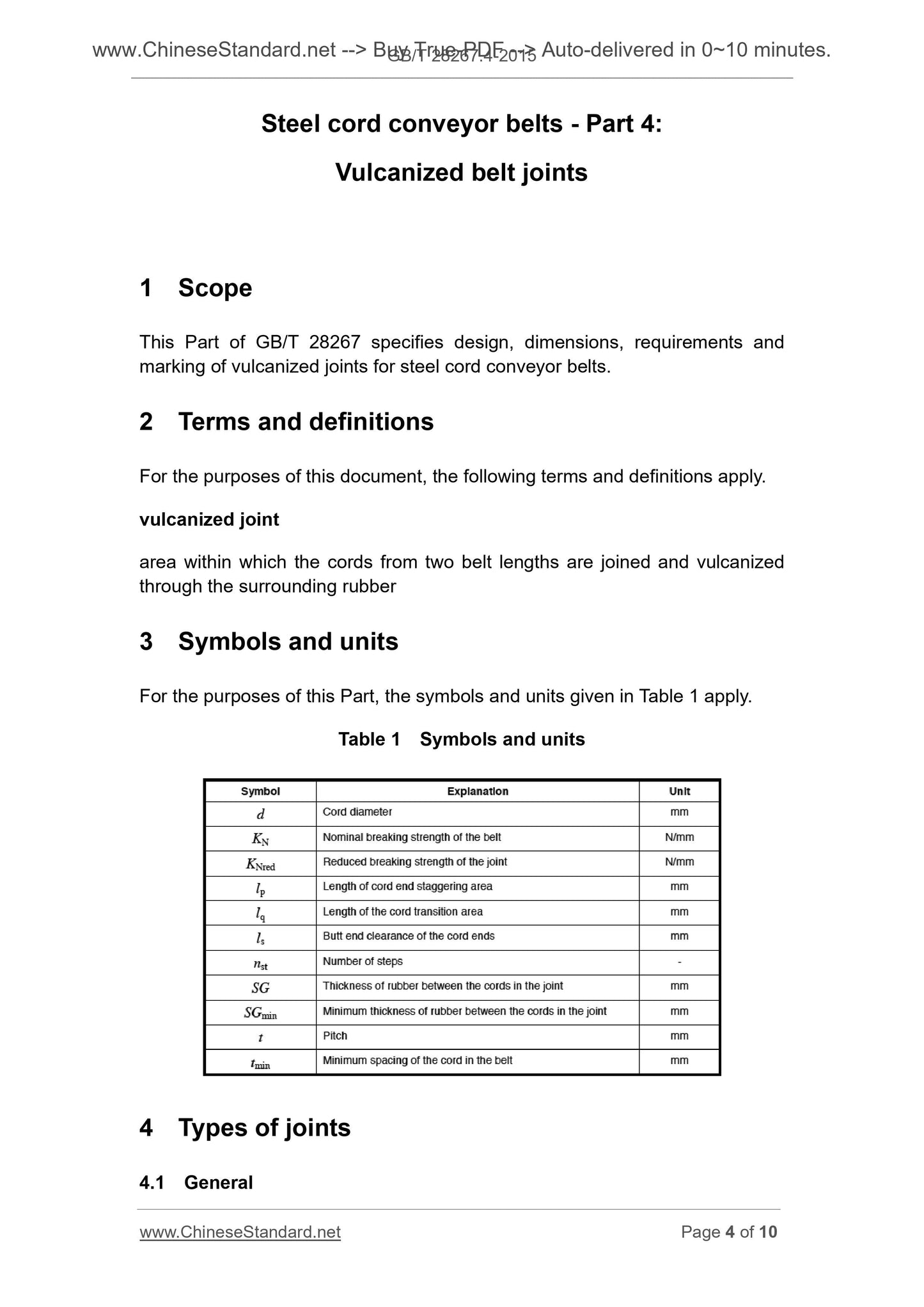

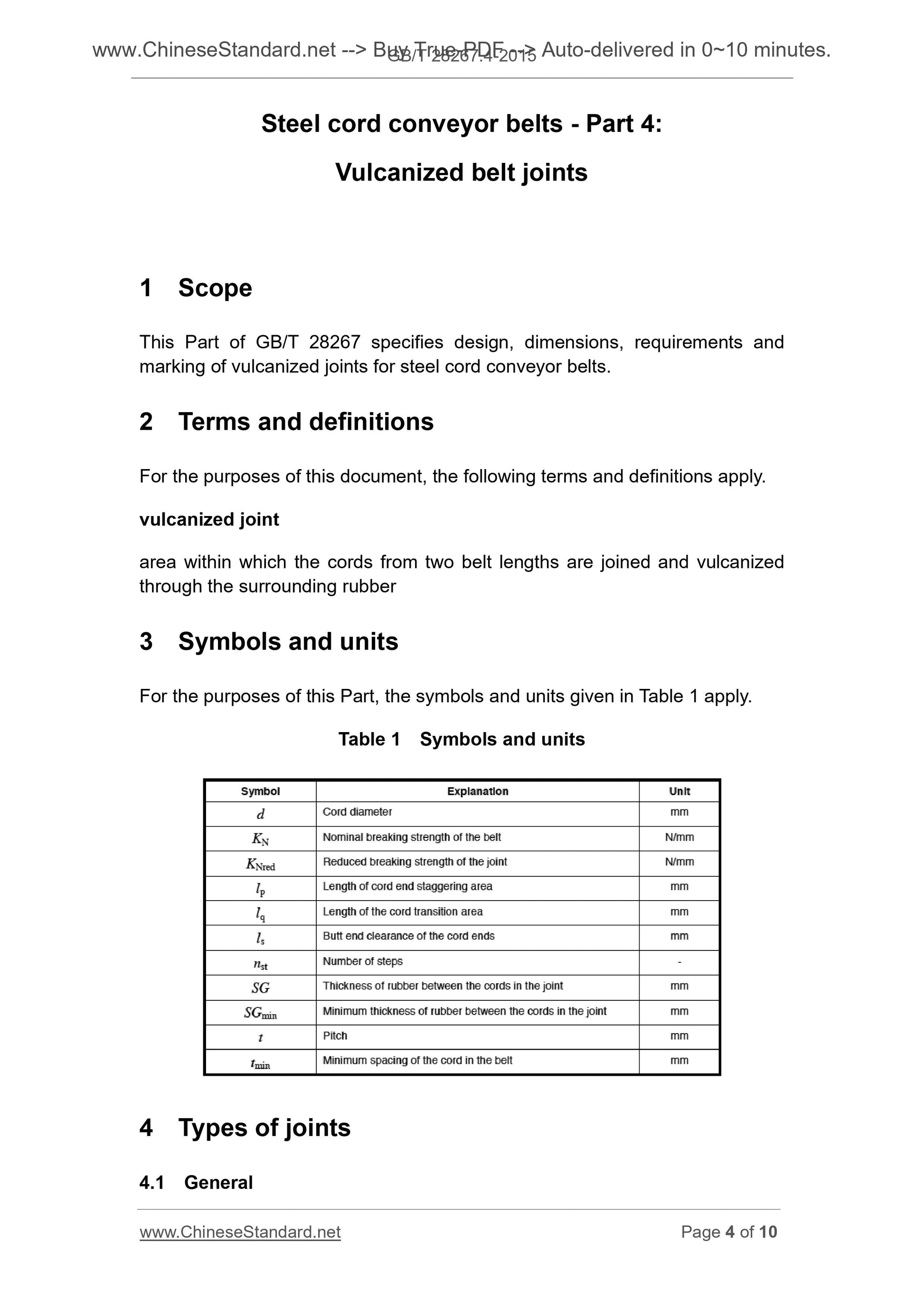

This Part of GB/T 28267 specifies design, dimensions, requirements andmarking of vulcanized joints for steel cord conveyor belts.

Basic Data

| Standard ID | GB/T 28267.4-2015 (GB/T28267.4-2015) |

| Description (Translated English) | Steel cord conveyor belts -- Part 4: Vulcanized belt joints |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | G42 |

| Classification of International Standard | 53.040.20 |

| Word Count Estimation | 11,123 |

| Date of Issue | 2015-12-31 |

| Date of Implementation | 2016-07-01 |

| Adopted Standard | ISO 15236-4-2004, IDT |

| Regulation (derived from) | State Standard Announcement 2015 No.43 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the design, dimensions, requirements and marking of vulcanized joints for steel cord conveyor belts. |

Share