1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 26980-2011 English PDF (GB/T26980-2011)

GB/T 26980-2011 English PDF (GB/T26980-2011)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

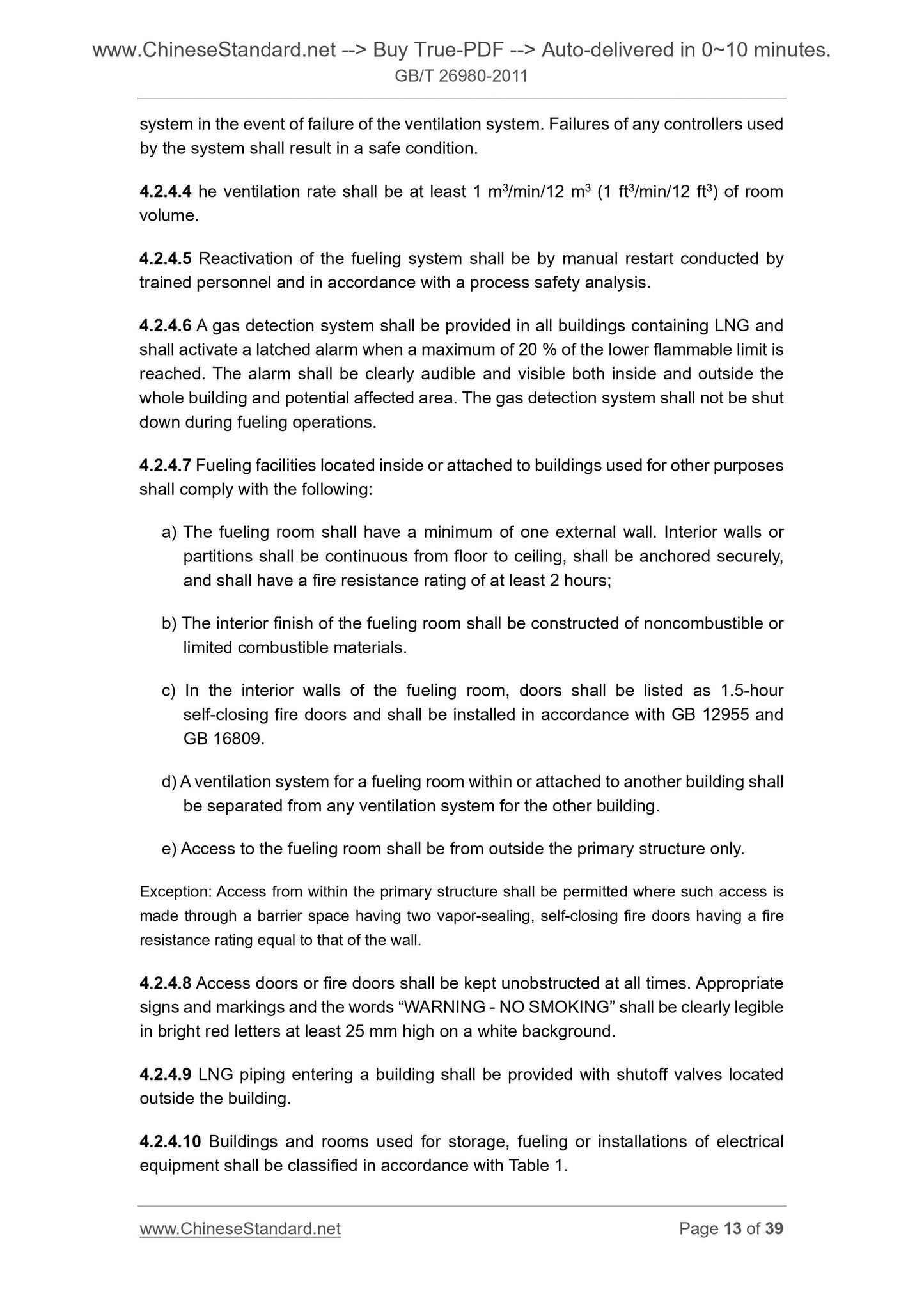

GB/T 26980-2011: Liquefied natural gas (LNG) vehicular fueling systems code

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 26980-2011 (Self-service in 1-minute)

Newer / historical versions: GB/T 26980-2011

Preview True-PDF

Scope

This Standard specifies the reasonable protection measures for the prevention of fireand explosion in the fueling facilities of liquefied natural gas (LNG) vehicular fueling

system.

This Standard apply to the design, installation, operation and maintenance of various

types of fueling facilities, with a container capacity of not more than 265 m3, of liquefied

natural gas (LNG) vehicular fueling system and LNG-CNG (compressed natural gas)

conversion facilities.

This Standard does not apply to facilities, equipment and structural devices that have

been built or approved for construction and installation prior to the entry into force of

this Standard, unless otherwise stated.

Basic Data

| Standard ID | GB/T 26980-2011 (GB/T26980-2011) |

| Description (Translated English) | Liquefied natural gas (LNG) vehicular fueling systems code |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | E24 |

| Classification of International Standard | 75.060 |

| Word Count Estimation | 25,219 |

| Date of Issue | 2011-09-29 |

| Date of Implementation | 2012-01-01 |

| Quoted Standard | GB 150-1998; GB 8624-2006; GB/T 8923-1988; GB 9448-1999; GB 12955-2008; GB 16809-2008; GB 18442-2001; GB/T 20368-2006; GB/T 20801-2006; GB 50016-2006; GB 50058-1992; GB 50191-1993; GB 50235-1997; JB/T 4711-2003; JB/T 6697-2006; ISO 15500 |

| Adopted Standard | NFPA 52-2006, MOD |

| Regulation (derived from) | National Standards Bulletin 2011 No. 14 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard applies to tank capacity not more than 265 cubic meters of various types of liquefied natural gas (LNG) fuel system of a vehicle filling facilities and LNG-CNG (Compressed Natural Gas) conversion facility design, installation, operation and maintenance. This standard does not apply to the entry into force of this standard have been built or have been approved for construction installation of facilities, equipment and structural equipment, unless otherwise stated. |

Share