1

/

of

8

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 26913-2011 English PDF (GB/T26913-2011)

GB/T 26913-2011 English PDF (GB/T26913-2011)

Regular price

$90.00

Regular price

Sale price

$90.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 26913-2011: Bamboo charcoal

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 26913-2011 (Self-service in 1-minute)

Newer / historical versions: GB/T 26913-2011

Preview True-PDF

Scope

This Standard specifies the terms and definitions, classification and mark, technicalrequirements, test methods, inspection rules, logo, label and package of bamboo

charcoal.

This Standard shall be applicable to bamboo charcoal made of bamboo through the

pyrolysis method.

2 Normative references

The articles contained in the following documents have become part of this Standard

when they are quoted herein. For the dated documents so quoted, all the modifications

(excluding corrections) or revisions made thereafter shall not be applicable to this

Standard. For the undated documents so quoted, the latest editions shall be applicable to

this Standard.

JJF 1070 Rules of Metrological Testing for Net Quantity of Products in Prepackages

with Fixed Content

Order No. 75 (2005) General Administration of Quality Supervision Provisions of the

Metrological Supervision and Administration of Quantitatively Packed Commodities

3 Terms and definitions

For the purpose of this standard, the following terms and definitions shall apply.

3.1

Bamboo charcoal

Under the conditions of high temperature and limited oxygen (or isolated oxygen), the

bamboo is heated through pyrolysis, so as to obtain the black solid.

3.2

Tube charcoal

The tubular bamboo charcoal.

groove depth. 4mm.

6.5.2.2 High temperature electric furnace. With temperature control device which can

maintain at (850±20)°C.

6.5.2.3 Crucible holder. Made of nichrome wire. Crucible’s size does not exceed the limit

of constant temperature region in the high temperature furnace. And MAKE the bottom of

the crucible on the shelf of the crucible to be 10mm - 15mm from the bottom of the

furnace.

6.5.2.4 Analytical balance. Sensitive of 0.1mg.

6.5.2.5 Stopwatch or time clock.

6.5.2.6 Dryer. with desiccant (Not-deliquescent bulk-shape calcium chloride or silica gel)

in it.

6.5.3 Operating methods

WEIGH 1g (accurate to 0.1mg) of test sample that has been crushed and gone through

0.315mm (55-mesh) sieve. PLACE in the porcelain crucible that has been burned to

constant weight at (850±20)°C. COVER the crucible. Gently SHAKE to make the test

sample spread out. PLACE it on the crucible shelf. Then, quickly PLACE it into the high

temperature electric furnace that has been pre-heated to 850°C. The crucible locates

above or below the measurement point of the thermocouple. CONTINUE to heat it for

7min. The temperature of furnace drops at the beginning, but shall be restored to

(850±20)°C within 3min. If there are obvious sparks, it shall be redone.

Finally, TAKE the crucible out and PLACE it on the porcelain plate. COOL it in the air for

5min. PLACE it in a dryer and COOL it to the room temperature. And WEIGH it.

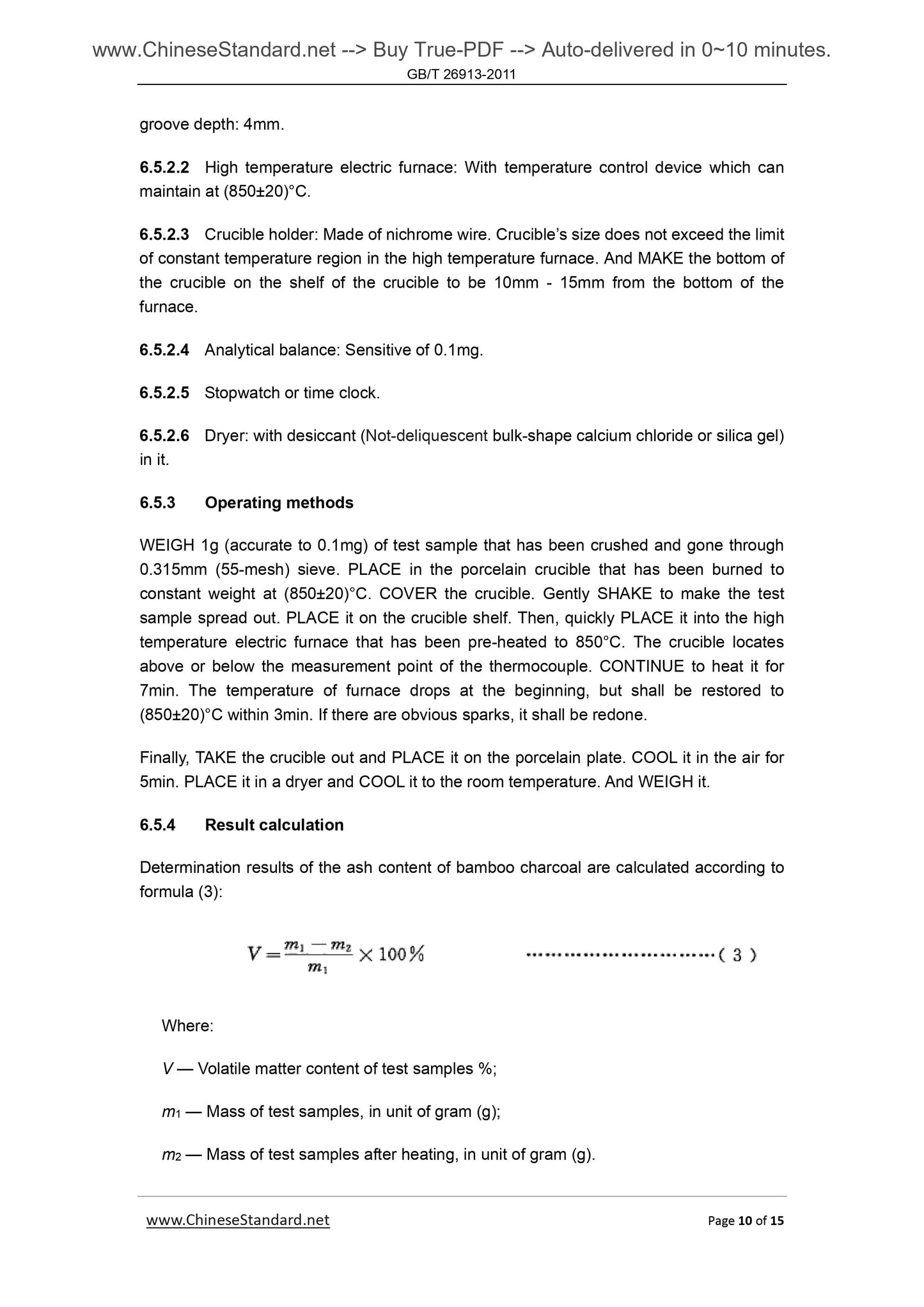

6.5.4 Result calculation

Determination results of the ash content of bamboo charcoal are calculated according to

formula (3).

Where.

V — Volatile matter content of test samples %;

m1 — Mass of test samples, in unit of gram (g);

m2 — Mass of test samples after heating, in unit of gram (g).

7.2.1 Ex-factory inspection

Ex-factory inspection shall be conducted for each batch of products. Ex-factory inspection

shall be performed by the quality inspection department of the manufacturer or entrusted

to third-party inspection agency. Inspection items are the sense, net content deviation,

and moisture.

7.2.2 Type inspection

Inspection items of type inspection include all items required in this Standard.

Type inspection shall be conducted, when there is one of the following conditions.

a) When the product production is resumed after a long-term shutdown;

b) Change of material or key production process which may affect product quality;

c) When national quality and supervision agency puts forward the request of type

inspection;

d) The Ex-factory inspection is quite different from the last type inspection;

e) During normal production, periodic inspection shall be conducted at least once a

year.

7.3 Decision rules

If one inspection result does not comply with the requirements defined in this Standard,

re-inspection shall be performed with double sampling. If the re-inspection result is still

unqualified, this batch of products shall be decided as unqualified.

8 Logo, Label, Package and Storage

8.1 Logo and label

Product logo shall include at least the following contents. product name and brand, type

specification, net content, executive standard, production date, quality level, manufacturer

name, production place, and factory address etc.

8.2 Package and storage

Product package shall be firm, clean and moisture-proof. Package material, type

specification and net weight of the same batch shall be consistent. Stipulations in the

contract otherwise shall prevail. Products shall be stored in shady, airy and dry warehouse,

away from fire source and prevented from exposing to the sun and rain. For safety

consideration, newly-burned bamboo charcoal shall be processed and packaged after

spreading-out for 3 days.

Basic Data

| Standard ID | GB/T 26913-2011 (GB/T26913-2011) |

| Description (Translated English) | Bamboo charcoal |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | B73 |

| Classification of International Standard | 65.020 |

| Word Count Estimation | 10,154 |

| Date of Issue | 2011-09-29 |

| Date of Implementation | 2011-12-01 |

| Quoted Standard | JJF 1070 |

| Regulation (derived from) | National Standards Bulletin 2011 No. 14 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

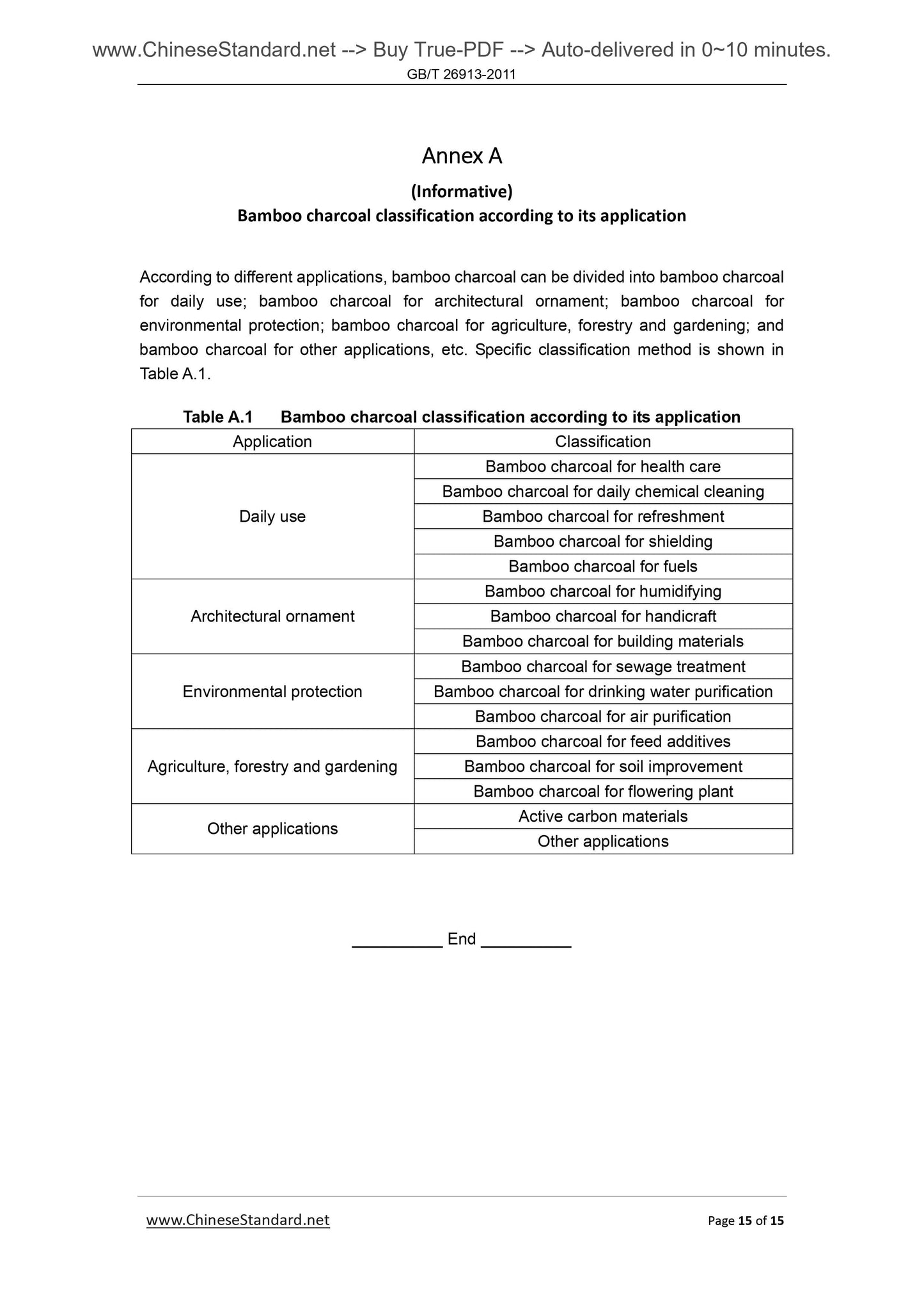

| Summary | This standard specifies the terms and definitions charcoal, classification and labeling, technical requirements, test methods, inspection rules, marking, labeling and packaging. This standard applies to bamboo as raw material obtained through pyrolysis of charcoal. |

Share