1

/

of

7

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 2625-1981 English PDF (GB/T2625-1981)

GB/T 2625-1981 English PDF (GB/T2625-1981)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

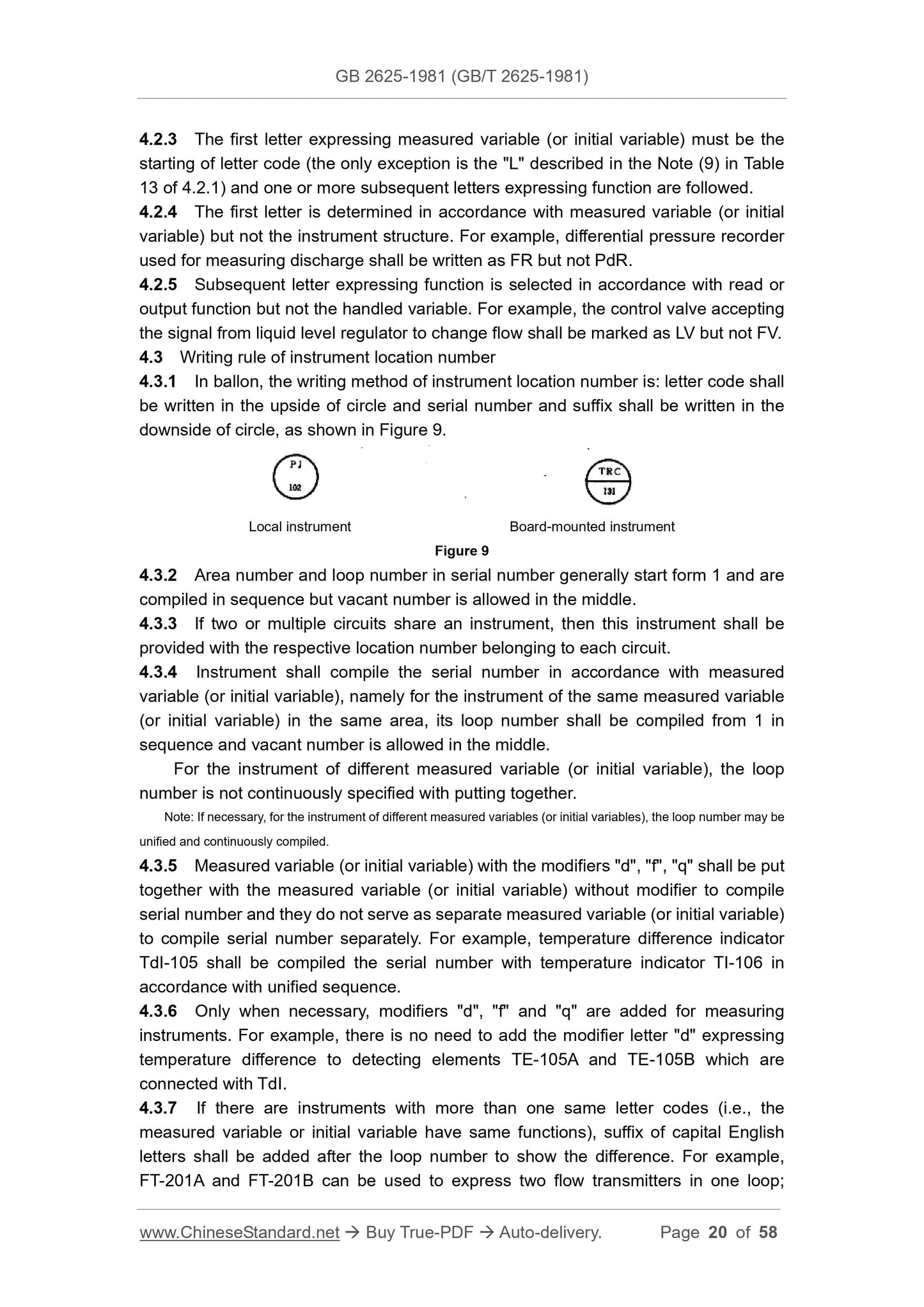

GB/T 2625-1981: Process detection and controlflow chart. Symbols and letter codes

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 2625-1981 (Self-service in 1-minute)

Newer / historical versions: GB/T 2625-1981

Preview True-PDF

Basic Data

| Standard ID | GB/T 2625-1981 (GB/T2625-1981) |

| Description (Translated English) | Process detection and controlflow chart. Symbols and letter codes |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | N10 |

| Classification of International Standard | 25.040.40 |

| Word Count Estimation | 55,589 |

| Date of Issue | 4/15/1981 |

| Date of Implementation | 3/1/1982 |

| Issuing agency(ies) | State Standards Administration |

| Summary | This Standard is applicable to chemical, petroleum, metallurgy, electric power, light industry, textiles, building materials and other industrial, instrumentation devices designed to detect and provides a flow chart of the process used to control a unified representation. |

Share