1

/

of

7

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 25930-2010 English PDF (GB/T25930-2010)

GB/T 25930-2010 English PDF (GB/T25930-2010)

Regular price

$190.00

Regular price

Sale price

$190.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

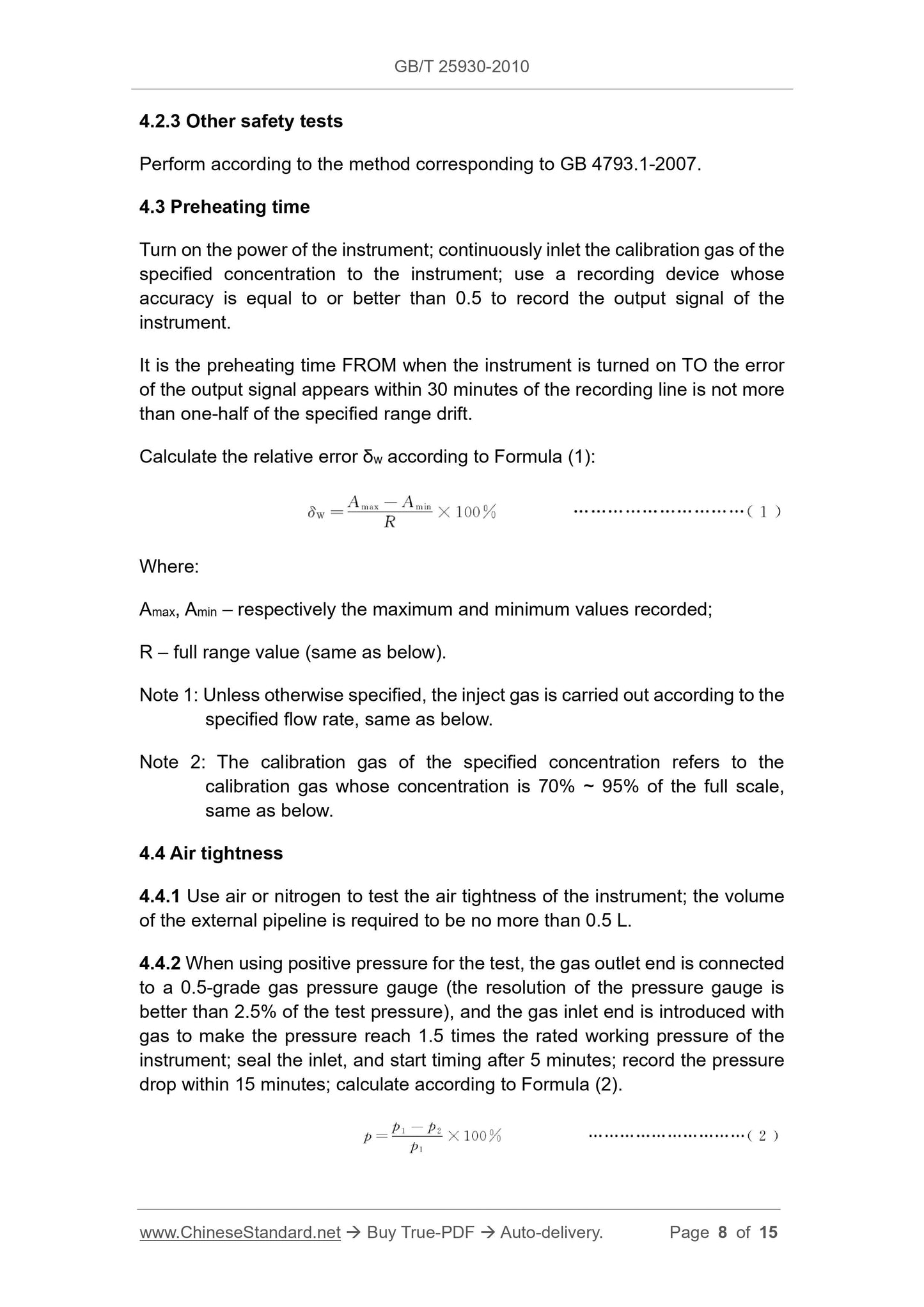

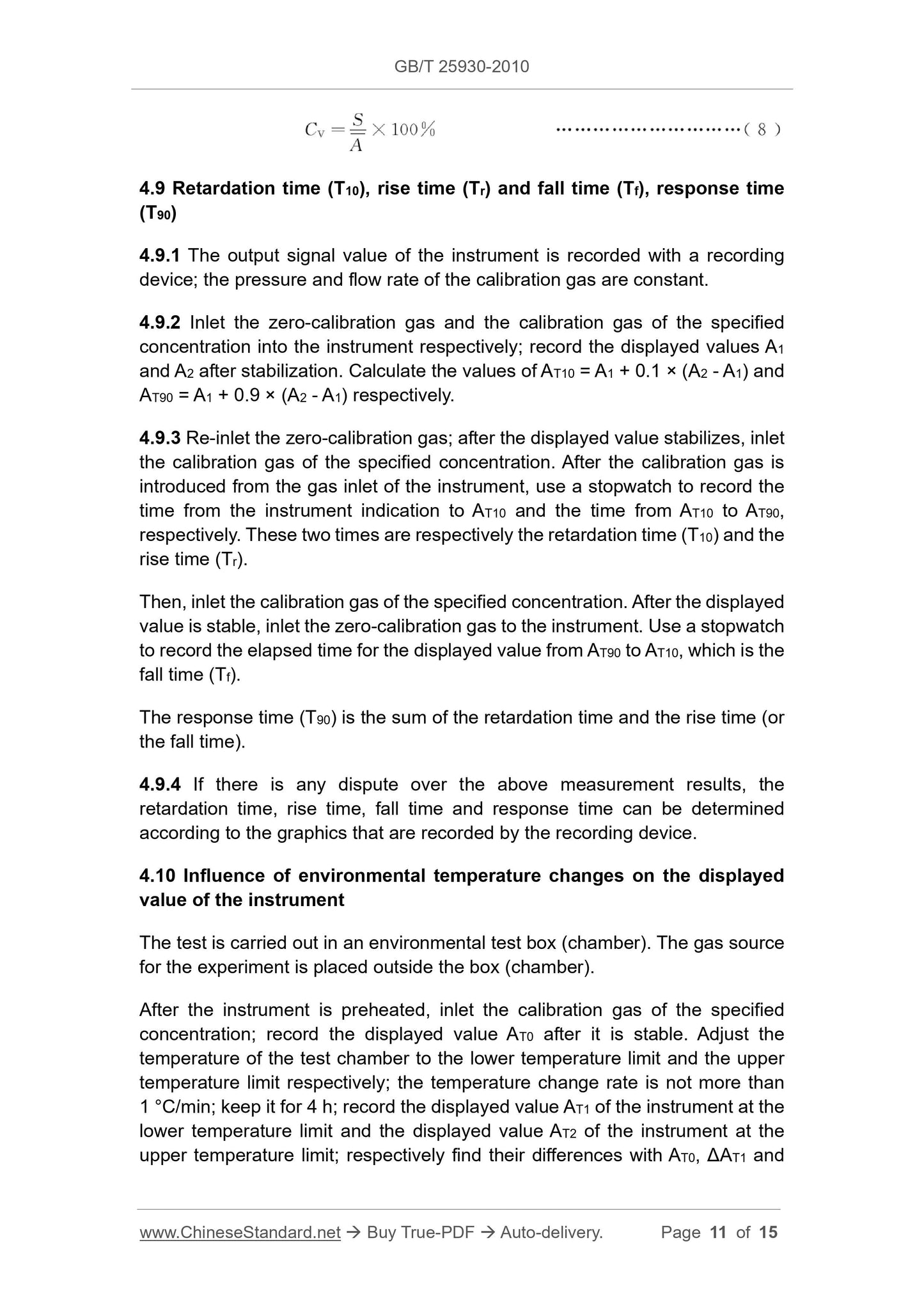

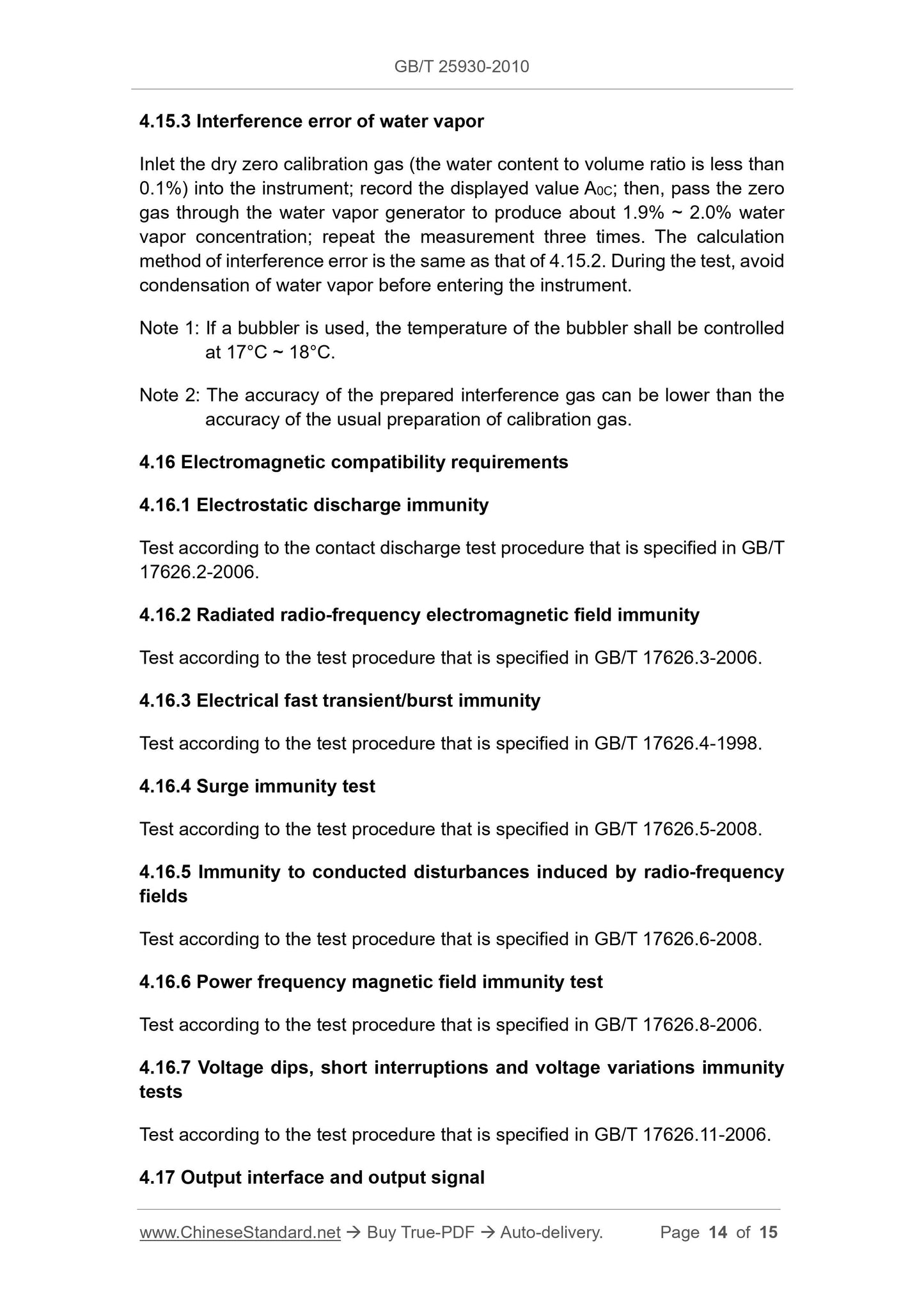

GB/T 25930-2010: Test method of infrared gas analyzers

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 25930-2010 (Self-service in 1-minute)

Newer / historical versions: GB/T 25930-2010

Preview True-PDF

Scope

This Standard specifies the test conditions, test items and test methods ofinfrared gas analyzers.

This Standard applies to the non-dispersive infrared gas analyzer (hereinafter

referred to as the instrument) for the continuous determination of one

component or several components in the mixed gas.

Basic Data

| Standard ID | GB/T 25930-2010 (GB/T25930-2010) |

| Description (Translated English) | Test method of infrared gas analyzers |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | N53 |

| Classification of International Standard | 71.040.01 |

| Word Count Estimation | 10,179 |

| Date of Issue | 1/14/2011 |

| Date of Implementation | 5/1/2011 |

| Quoted Standard | GB 4793.1-2007; GB/T 11606-2007; GB/T 17626.2-2006; GB/T 17626.3-2006; GB/T 17626.4-2008; GB/T 17626.5-2008; GB/T 17626.6-2008; GB/T 17626.8-2006; GB/T 17626.11-2008 |

| Regulation (derived from) | Announcement of Newly Approved National Standards No. 2 of 2011 |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This Standard specifies the infrared gas analyzer test conditions, test items and test methods. This Standard is applicable to continuous measurement, regardless of the gas mixture of a component or several components of optical infrared gas analyzer (hereinafter referred to as the instrument). |

Share