1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 25787-2010 English PDF (GB/T25787-2010)

GB/T 25787-2010 English PDF (GB/T25787-2010)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 25787-2010: 4,4-Sulfonyldiphenol (Bisphenol-S)

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 25787-2010 (Self-service in 1-minute)

Newer / historical versions: GB/T 25787-2010

Preview True-PDF

Scope

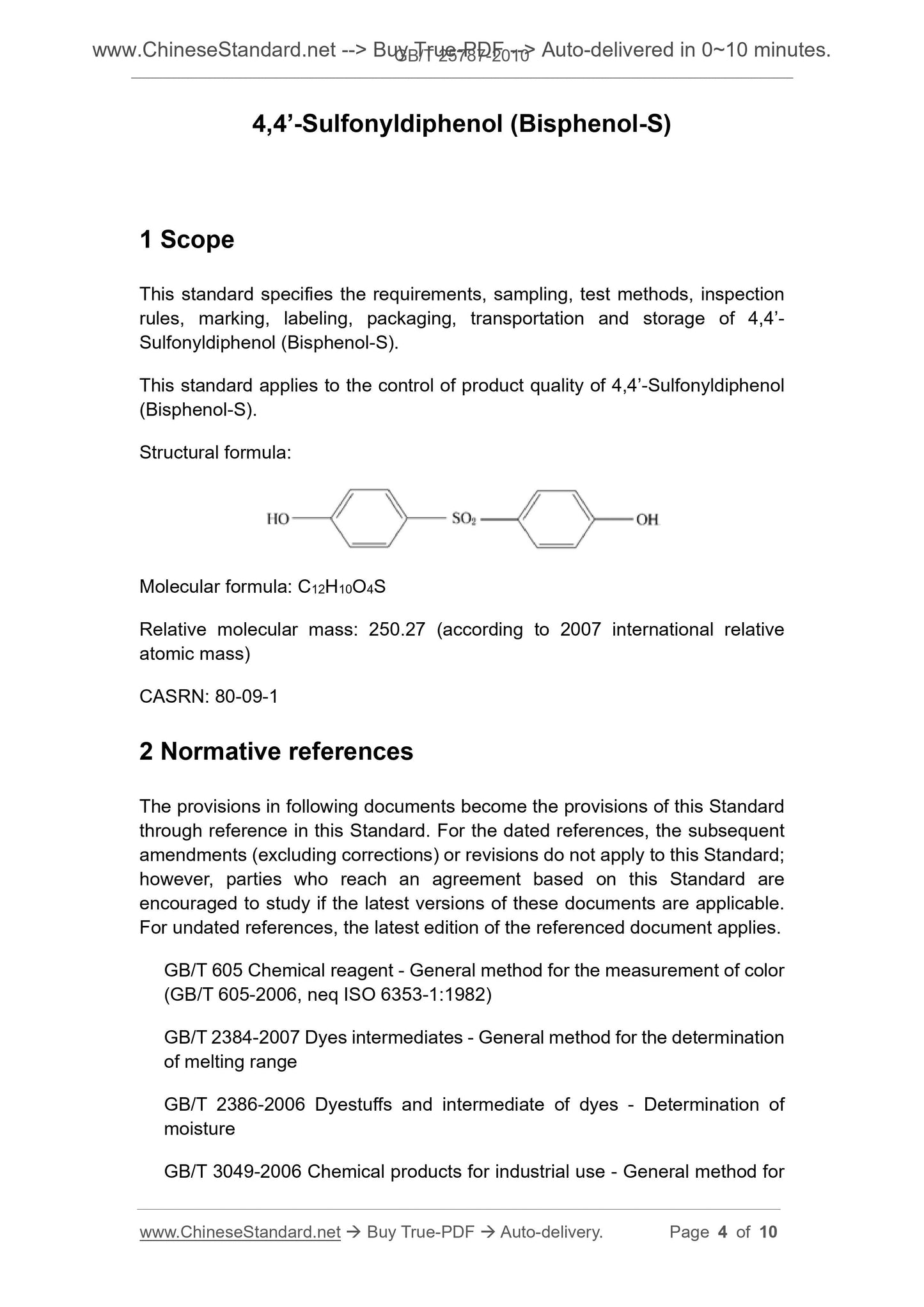

This standard specifies the requirements, sampling, test methods, inspectionrules, marking, labeling, packaging, transportation and storage of 4,4’-

Sulfonyldiphenol (Bisphenol-S).

This standard applies to the control of product quality of 4,4’-Sulfonyldiphenol

(Bisphenol-S).

Structural formula.

Molecular formula. C12H10O4S

Relative molecular mass. 250.27 (according to 2007 international relative

atomic mass)

CASRN. 80-09-1

Basic Data

| Standard ID | GB/T 25787-2010 (GB/T25787-2010) |

| Description (Translated English) | 4,4-Sulfonyldiphenol (Bisphenol-S) |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | G56 |

| Classification of International Standard | 71.100.01; 87.060.10 |

| Word Count Estimation | 8,813 |

| Date of Issue | 2010-12-23 |

| Date of Implementation | 2011-10-01 |

| Quoted Standard | GB/T 605; GB/T 2384-2007; GB/T 2386-2006; GB/T 3049-2006; GB/T 6678-2003; GB/T 6682; GB/T 8170-2008; GB/T 21876 - 2008 |

| Regulation (derived from) | National Standard Approval Announcement 2010 No.10 (Total No.165) |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the 4, 4 '-dihydroxy diphenyl sulfone (bisphenol S) requirements, sampling, test methods, inspection rules and signs, labels, packaging, transport and storage. This standard applies to 4, 4 '-dihydroxy diphenyl sulfone product quality control. |

Share