1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 2546.1-2022 English PDF (GB/T2546.1-2022)

GB/T 2546.1-2022 English PDF (GB/T2546.1-2022)

Regular price

$230.00

Regular price

Sale price

$230.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 2546.1-2022: Plastics - Polypropylene (PP) moulding and extrusion materials - Part 1: Designation system and basis for specifications

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 2546.1-2022 (Self-service in 1-minute)

Newer / historical versions: GB/T 2546.1-2022

Preview True-PDF

Scope

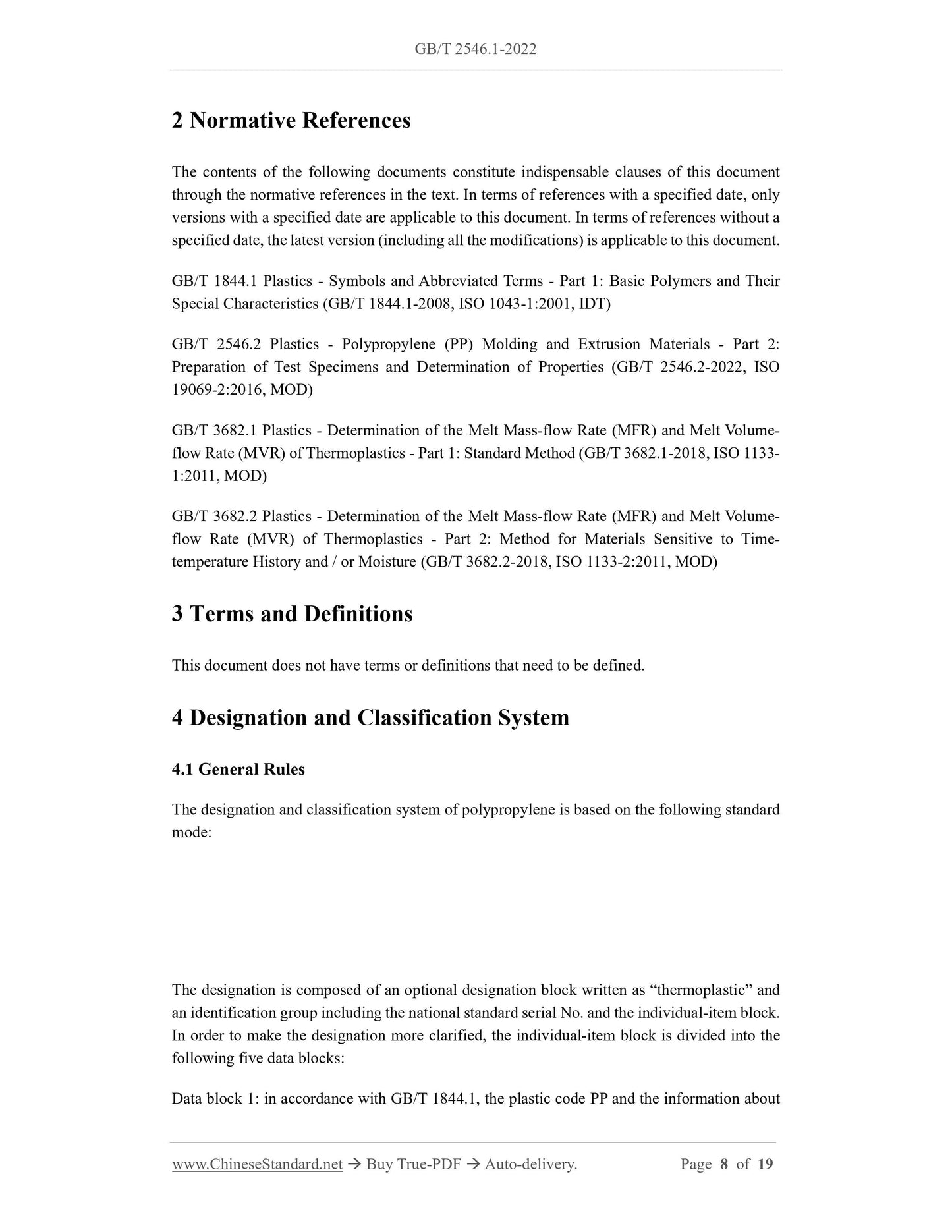

This document specifies the designation system of polypropylene (PP) thermoplastic materials,and this system can be used as the basis for specifications.

Different types of polypropylene thermoplastic materials are distinguished by a classification

system based on the following specified characteristic property values and recommended

purposes and (or) processing methods, important properties, additives, colorants, fillers and

reinforcing materials, etc.:

a) tensile elastic modulus;

b) Charpy notched impact strength;

c) melt mass-flow rate (MFR).

This document is applicable to all propylene homopolymers and other propylene copolymers

with a mass fraction of 1-olefin monomers less than 50% and blends of the above-mentioned

polymers with a mass fraction of not less than 50%.

This document is applicable to materials that are conventionally in the form of powders,

granules or crumbs, unmodified or modified by colorants, additives and fillers, etc.

This document does not apply to propylene-based rubber.

This document does not imply that materials with the same designation will necessarily have

identical properties. This document does not provide the engineering data, property data or

processing condition data necessary to describe a particular purpose and (or) processing method

for the materials.

If necessary, these additional properties can be determined in accordance with the test methods

specified in GB/T 2546.2.

In order to illustrate a particular purpose of a certain polypropylene thermoplastic material or

to ensure the reproducibility of processing, additional requirements may be provided in data

block 5.

Basic Data

| Standard ID | GB/T 2546.1-2022 (GB/T2546.1-2022) |

| Description (Translated English) | Plastics - Polypropylene (PP) moulding and extrusion materials - Part 1: Designation system and basis for specifications |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | G31 |

| Word Count Estimation | 14,159 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share