1

/

of

5

PayPal, credit cards. Download editable-PDF & invoice In 1 second!

GB/T 2546.1-2006 English PDF (GB/T2546.1-2006)

GB/T 2546.1-2006 English PDF (GB/T2546.1-2006)

Regular price

$70.00

Regular price

Sale price

$70.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 2546.1-2006: Plastics -- Polypropylene (PP) moulding and extrusion materials -- Part 1: Designation system and basis for specifications

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 2546.1-2006 (Self-service in 1-minute)

Newer / historical versions: GB/T 2546.1-2006

Preview True-PDF

Scope

1.1 This Part of GB/T 2546 establishes a system of designation for polypropylene (PP)thermoplastic material, which may be used as the basis for specifications.

1.2 The types of polypropylene thermoplastic materials are differentiated from each

other by a classification system based on appropriate levels of the designatory

properties, and on information about the intended application and/or method of

processing, important properties, additives, colorants, fillers and reinforcing materials.

a) tensile elastic modulus;

b) notched/un-notched Charpy impact strength;

c) melt mass-flow rate (MFR).

1.3 This Part is applicable to all propylene homopolymers and to copolymers of

propylene with a content of other 1-olefins of less than 50 % (m/m), as well as blends

of polymers containing at least 50 % (m/m) of aforementioned polymers.

This Part applies to materials ready for normal use in the form of powder, granules or

pellets and to materials unmodified or modified by colorants. additives, fillers, etc.

This Part does not apply to propylene-based rubber.

1.4 This Part is not intended to imply that materials having the same designation give

necessarily the same performance. This Part does not provide engineering data,

performance data or data on processing conditions which may be required to specify

a material for a particular application and/or method of processing.

If such additional properties are required, they shall be determined in accordance with

the test methods specified in Clause 2 of this Standard, if suitable.

1.5 In order to specify a thermoplastic material for a particular application or to ensure

reproducible processing, additional requirements may be given in data block 5.

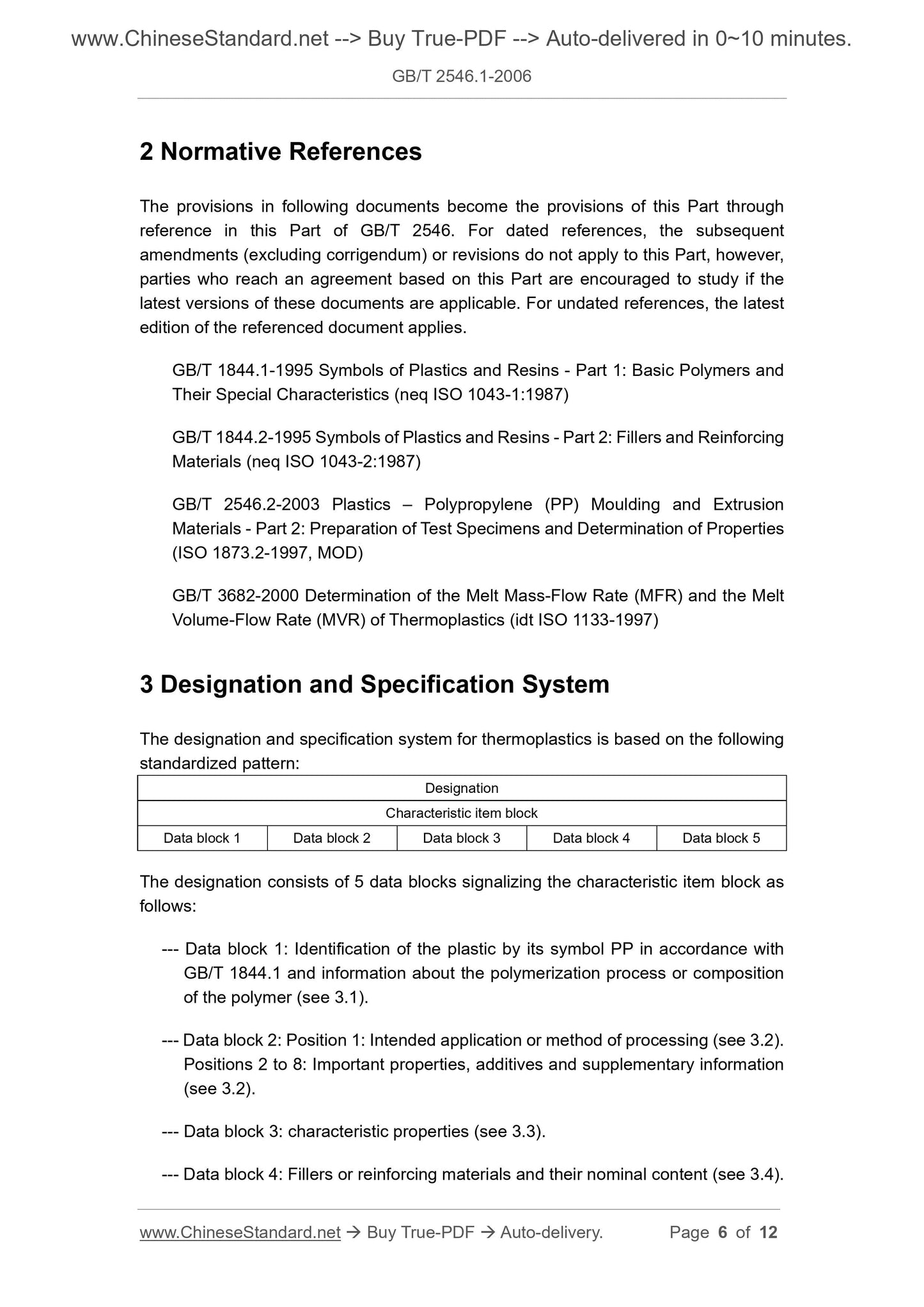

Basic Data

| Standard ID | GB/T 2546.1-2006 (GB/T2546.1-2006) |

| Description (Translated English) | Plastics -- Polypropylene (PP) moulding and extrusion materials -- Part 1: Designation system and basis for specifications |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | G31 |

| Classification of International Standard | 83.080.20 |

| Word Count Estimation | 9,970 |

| Date of Issue | 2006-01-23 |

| Date of Implementation | 2006-11-01 |

| Older Standard (superseded by this standard) | GB/T 2546-1988 |

| Quoted Standard | GB/T 1844.1-1995; GB/T 1844.2-1995; GB/T 2546.2-2003; GB/T 3682-2000 |

| Adopted Standard | ISO 1873-1-1995, MOD |

| Regulation (derived from) | National Standard Approval Announcement 2006 No.9 (Total No.96) |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the polypropylene (PP) thermoplastic material naming system. The system can be used as the basis for classification. Important properties, , 1. 2 Different types of polypropylene thermoplastic material with the following characteristics specified performance values, and recommended use and (or) method of processing additives, coloring agents, fillers and reinforcing materials distinction based on a classification system: a) tensile modulus, b) Charpy notched impact strength, c) melt mass flow rate (MER). 1. 3 section applies to all of propylene homopolymer and Other 1-olefin monomer concentration of less than 50 % of the propylene copolymers and blends of these polymers is not less than 50% of the mass fraction of. This section is applicable to conventional powder, granules or crushed granular unmodified or after coloring agents, additives, fillers such as modified material. This section does not apply to propylene-based rubber. 1. 4 part does not necessarily mean that the naming of the same material with the same properties. Description This section does not provide for engineering data and materials for special purposes (or) processing methods required, performance data or data processing conditions. If needed, according to the standard test methods specified in Part 2 to determine these additional properties. 1. 5 In order to illustrate a special-purpose polypropylene or processed in order to ensure reproducibility, additional requirements may be given in the fifth group of characters. |

Share