1

/

of

5

PayPal, credit cards. Download editable-PDF & invoice In 1 second!

GB/T 2523-2008 English PDF (GB/T2523-2008)

GB/T 2523-2008 English PDF (GB/T2523-2008)

Regular price

$165.00

Regular price

Sale price

$165.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

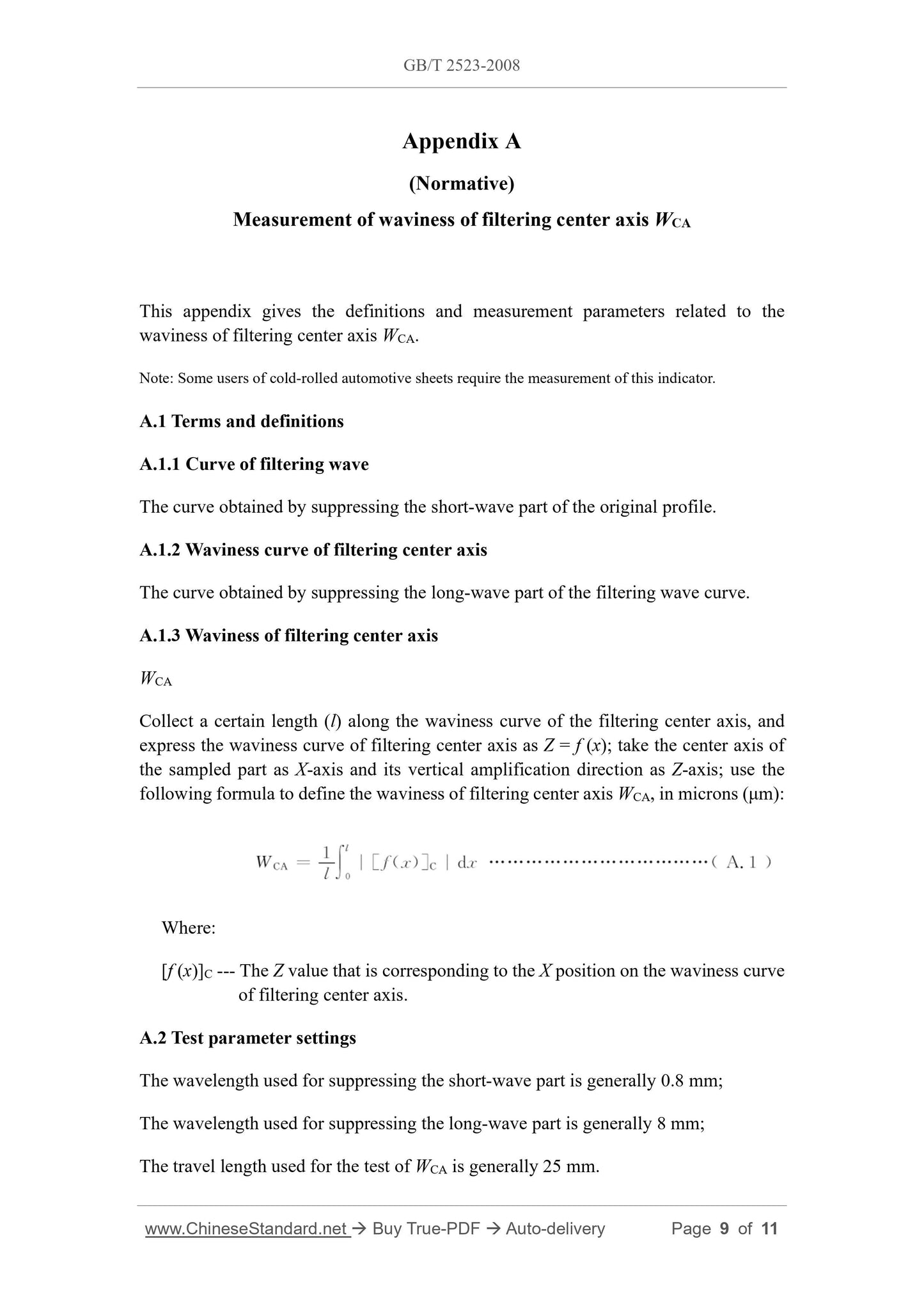

GB/T 2523-2008: Measuring method of surface roughness and peak count for cold-rolled metal sheet (strip)

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 2523-2008 (Self-service in 1-minute)

Newer / historical versions: GB/T 2523-2008

Preview True-PDF

Scope

This standard specifies the terms and definitions, test requirements, measurementprocess and results, and test reports of the surface roughness and the peak count of cold-

rolled metal sheets (strips).

This standard applies to the measurement of the surface roughness and the peak count

of cold-rolled metal sheets (strips).

Basic Data

| Standard ID | GB/T 2523-2008 (GB/T2523-2008) |

| Description (Translated English) | Measuring method of surface roughness and peak count for cold-rolled metal sheet (strip) |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | H21 |

| Classification of International Standard | 77.040.99 |

| Word Count Estimation | 9,933 |

| Date of Issue | 2008-10-10 |

| Date of Implementation | 2009-05-01 |

| Older Standard (superseded by this standard) | GB/T 2523-1990 |

| Quoted Standard | GB/T 3505-2000 |

| Adopted Standard | SAE J911-1998, NEQ |

| Regulation (derived from) | National Standard Approval Announcement 2008 No.17 (Total No.130) |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the terms and definitions of cold-rolled sheet metal (with) the surface roughness and the peak number, testing requirements, measurement process and results and test reports. This standard applies to the measurement of cold-rolled sheet metal (with) the surface roughness and the peak number. |

Share