1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 25087-2010 English PDF (GB/T25087-2010)

GB/T 25087-2010 English PDF (GB/T25087-2010)

Regular price

$125.00

Regular price

Sale price

$125.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 25087-2010: Road vehicles -- Round, screened and unscreened 60V and 600V multi-core sheathed cables

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 25087-2010 (Self-service in 1-minute)

Newer / historical versions: GB/T 25087-2010

Preview True-PDF

Scope

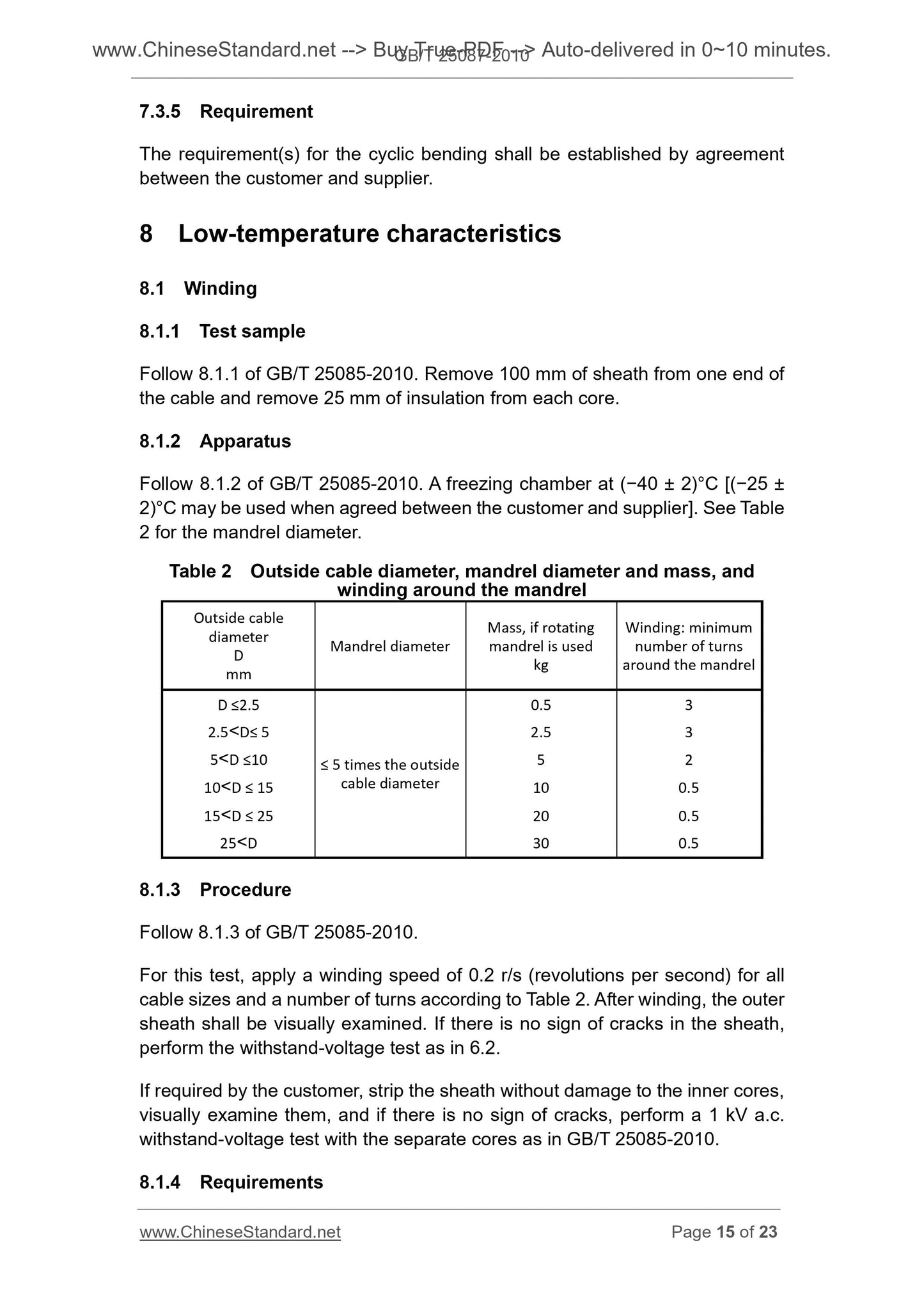

This standard specifies the test methods for basic performance and high performance of round, shielded and unshielded multi-core sheathed cables for road vehicles.Law and requirements.

The individual cores of unshielded cables shall comply with the requirements of GB/T 25085-2010. Other types of cores can also be used, but be sure

The structure and testing required for these core functions shall be determined by negotiation between the supplier and the purchaser. See GB/T 25085-2010 for temperature grades.

Basic Data

| Standard ID | GB/T 25087-2010 (GB/T25087-2010) |

| Description (Translated English) | Road vehicles -- Round, screened and unscreened 60V and 600V multi-core sheathed cables |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | T36 |

| Classification of International Standard | 43.040.10 |

| Word Count Estimation | 14,167 |

| Date of Issue | 2010-09-02 |

| Date of Implementation | 2011-02-01 |

| Quoted Standard | GB/T 25085-2010; GB/T 2951.11; GB/T 16422.2; GB/T 17737.1 |

| Adopted Standard | ISO 14572-2006, IDT |

| Regulation (derived from) | Announcement of Newly Approved National Standards No. 4 of 2010 (total 159) |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the circular road vehicles, shielded and unshielded multi-core sheathed cables in facsimile and high performance aspects of the test methods and requirements. Unshielded cables single core should be consistent with GB/T 25085-2010 requirements. You can also use other types of wires, but to ensure that these core functions required for construction and testing shall be determined by mutual agreement for Confucianism. Temperature ratings see GB/T 25085-2010. |

Share