1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 24595-2020 English PDF (GB/T24595-2020)

GB/T 24595-2020 English PDF (GB/T24595-2020)

Regular price

$145.00

Regular price

Sale price

$145.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 24595-2020: Hot-rolled steel bars for quenched and tempered automobile crankshafts

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 24595-2020 (Self-service in 1-minute)

Newer / historical versions: GB/T 24595-2020

Preview True-PDF

Scope

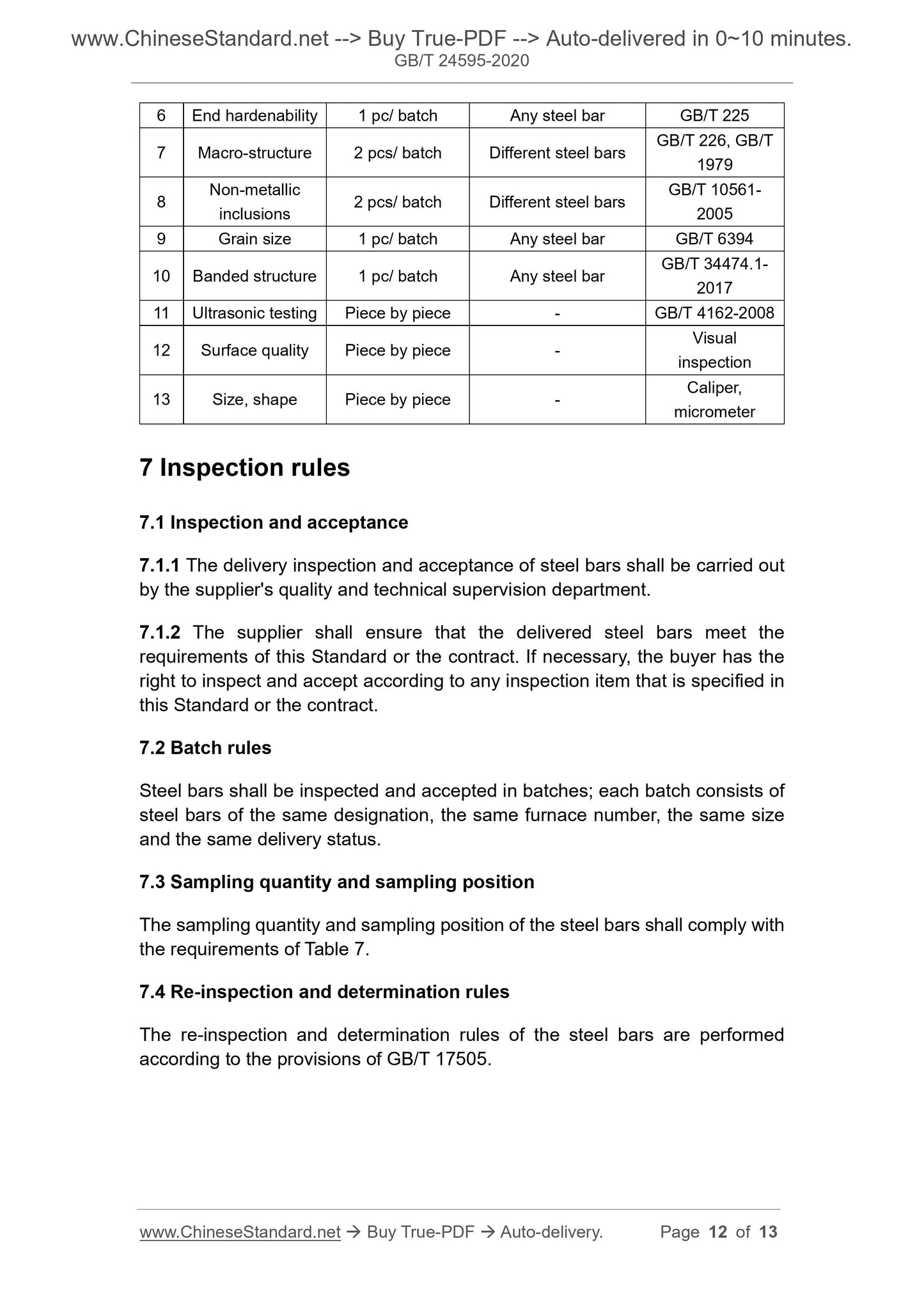

This Standard specifies the order content, size, shape, weight, technicalrequirements, test methods, inspection rules, packaging, marking and quality

certificates of hot-rolled steel bars for quenched and tempered automobile

crankshafts.

This Standard applies to hot-rolled steel bars whose nominal diameter is not

greater than 200 mm (hereinafter referred to as steel bars).

Basic Data

| Standard ID | GB/T 24595-2020 (GB/T24595-2020) |

| Description (Translated English) | Hot-rolled steel bars for quenched and tempered automobile crankshafts |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | H54 |

| Classification of International Standard | 77.140.60 |

| Word Count Estimation | 10,148 |

| Date of Issue | 2020-03-06 |

| Date of Implementation | 2020-10-01 |

| Issuing agency(ies) | State Administration for Market Regulation, China National Standardization Administration |

Share