1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 23988-2009 English PDF (GB/T23988-2009)

GB/T 23988-2009 English PDF (GB/T23988-2009)

Regular price

$105.00

Regular price

Sale price

$105.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

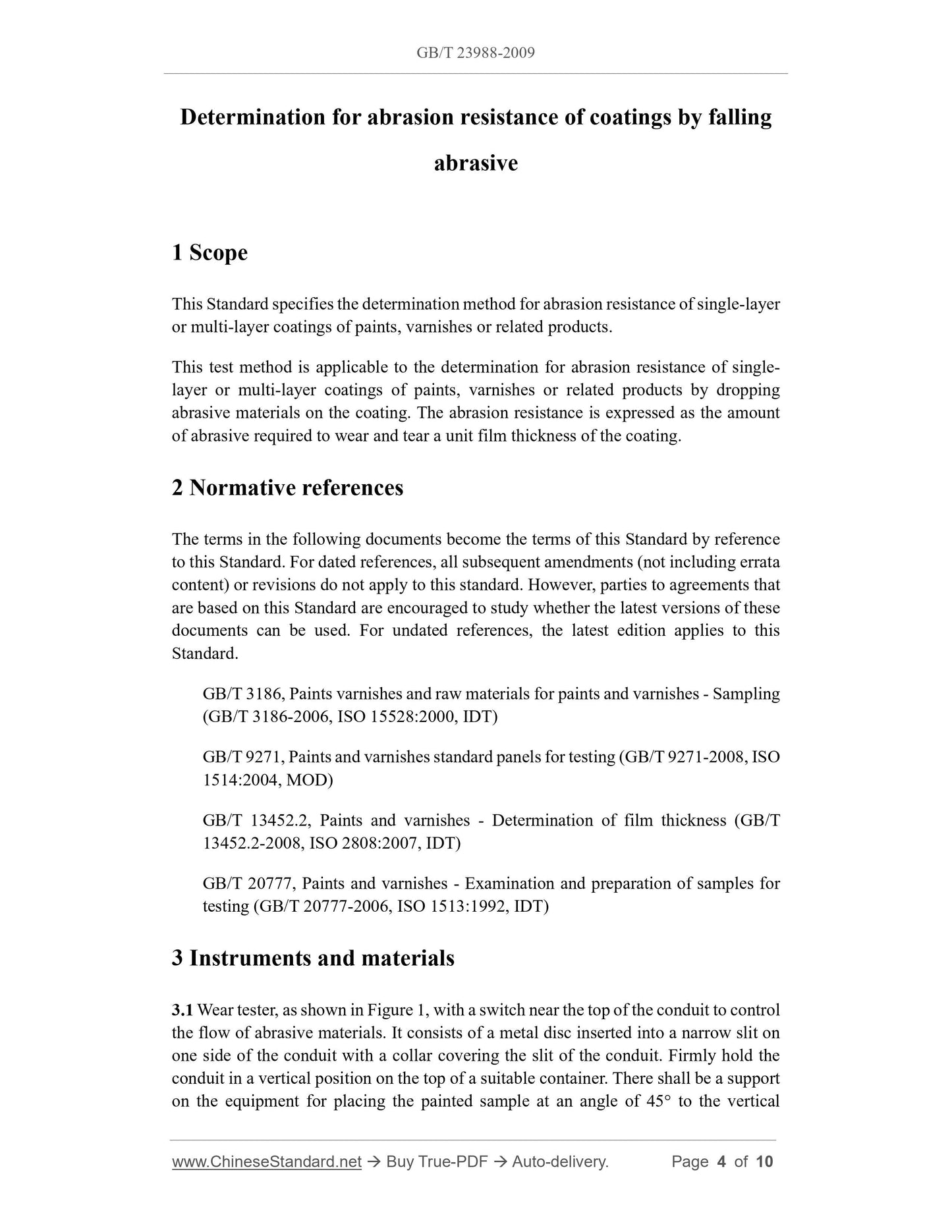

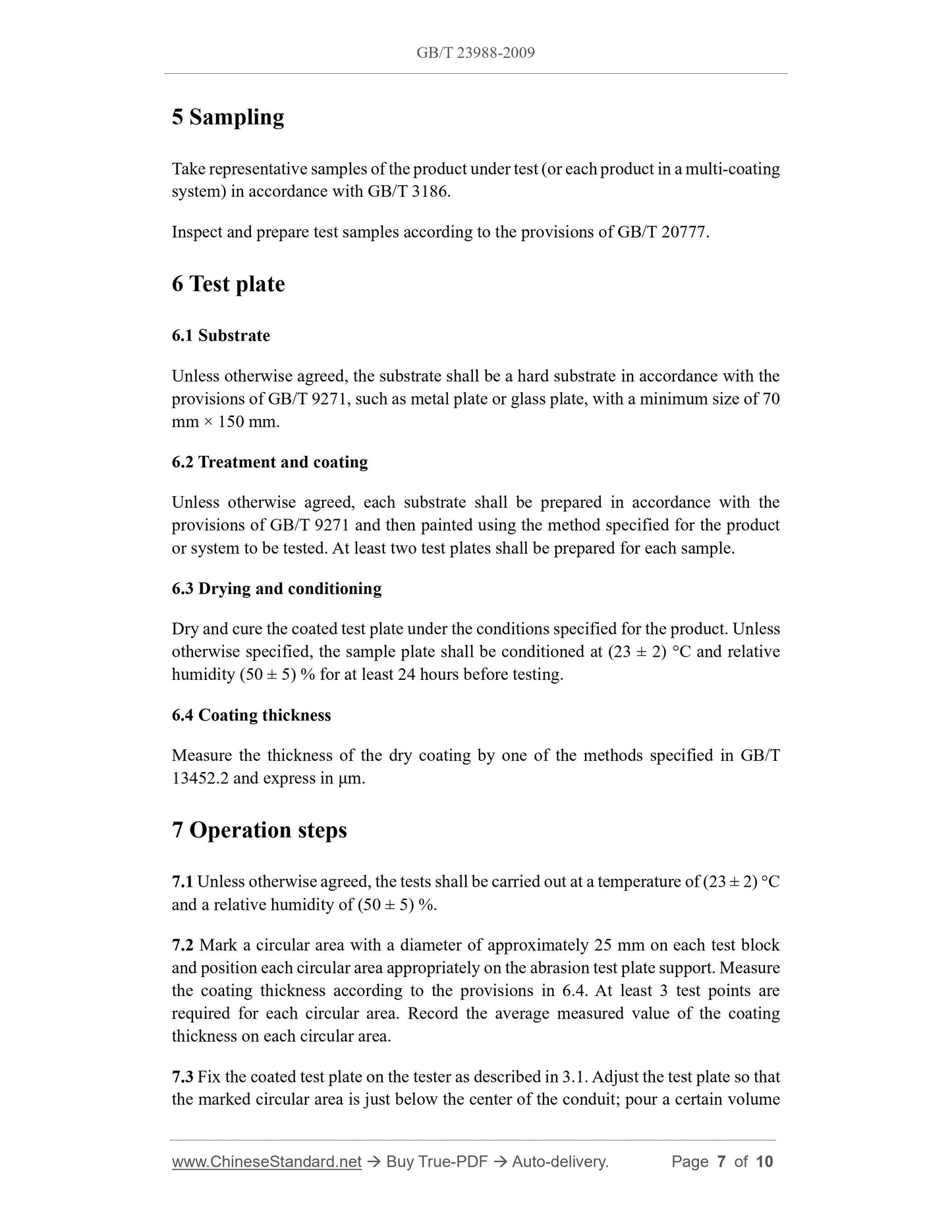

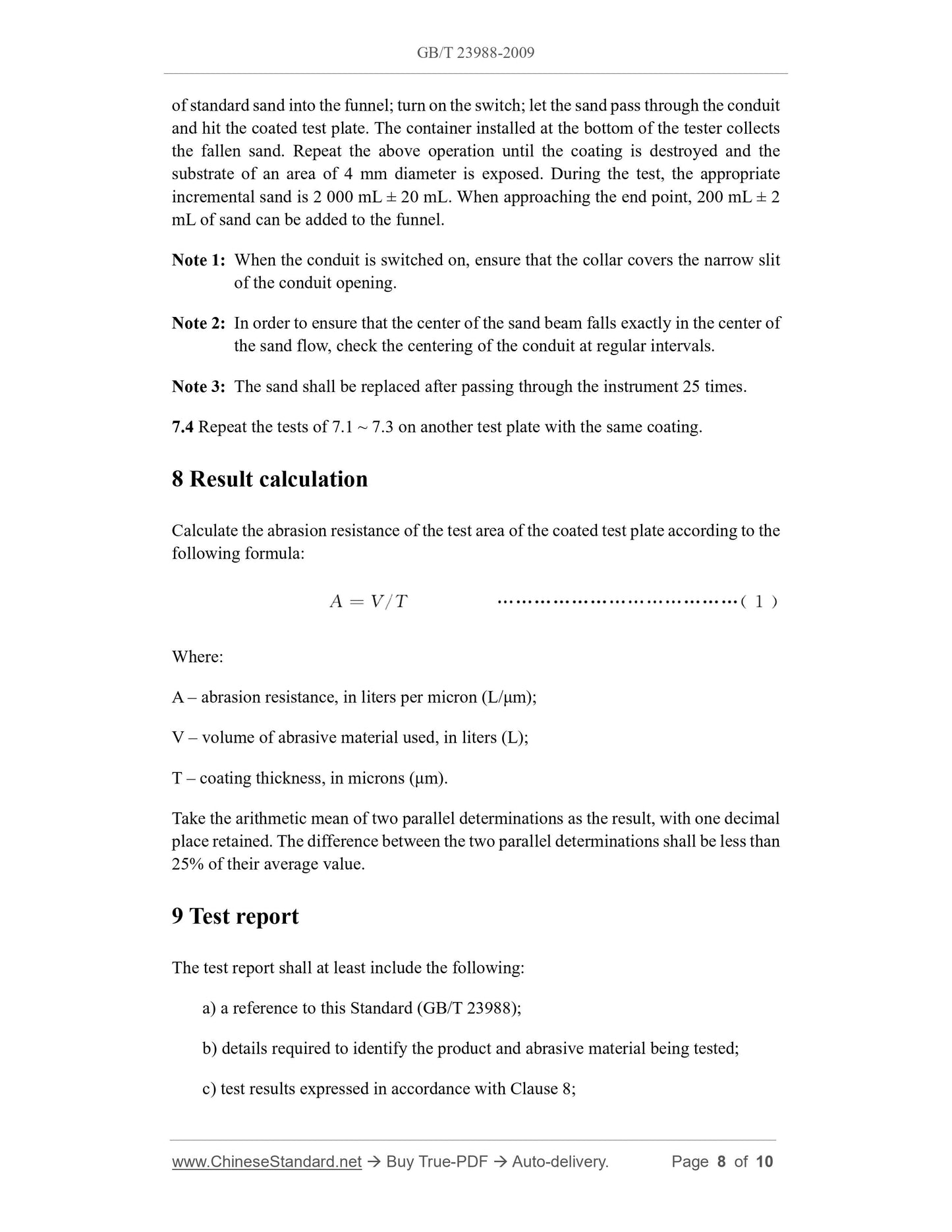

GB/T 23988-2009: Determination for abrasion resistance of coatings by falling abrasive

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 23988-2009 (Self-service in 1-minute)

Newer / historical versions: GB/T 23988-2009

Preview True-PDF

Scope

This Standard specifies the determination method for abrasion resistance of single-layeror multi-layer coatings of paints, varnishes or related products.

This test method is applicable to the determination for abrasion resistance of single-

layer or multi-layer coatings of paints, varnishes or related products by dropping

abrasive materials on the coating. The abrasion resistance is expressed as the amount

of abrasive required to wear and tear a unit film thickness of the coating.

Basic Data

| Standard ID | GB/T 23988-2009 (GB/T23988-2009) |

| Description (Translated English) | Determination for abrasion resistance of coatings by falling abrasive |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | G50 |

| Classification of International Standard | 87.040 |

| Word Count Estimation | 8,841 |

| Date of Issue | 2009-06-02 |

| Date of Implementation | 2010-02-01 |

| Quoted Standard | GB/T 3186; GB/T 9271; GB/T 13452.2; GB/T 20777 |

| Regulation (derived from) | Announcement of Newly Approved National Standards No. 8, 2009 (No. 148 overall) |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the paint, varnish or related product or multi- layer film coating abrasion resistance measurement method. This test method is applicable to fall through the abrasive coating measured up paint, varnish or related product or multi- layer film coating wear resistance. Abrasion-resistant coating to the desired thickness of the unit amount of said abrasive wear resistance. |

Share