1

/

of

9

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 23333-2009 English PDF (GB/T23333-2009)

GB/T 23333-2009 English PDF (GB/T23333-2009)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 23333-2009: Evaporative air cooler

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 23333-2009 (Self-service in 1-minute)

Newer / historical versions: GB/T 23333-2009

Preview True-PDF

Scope

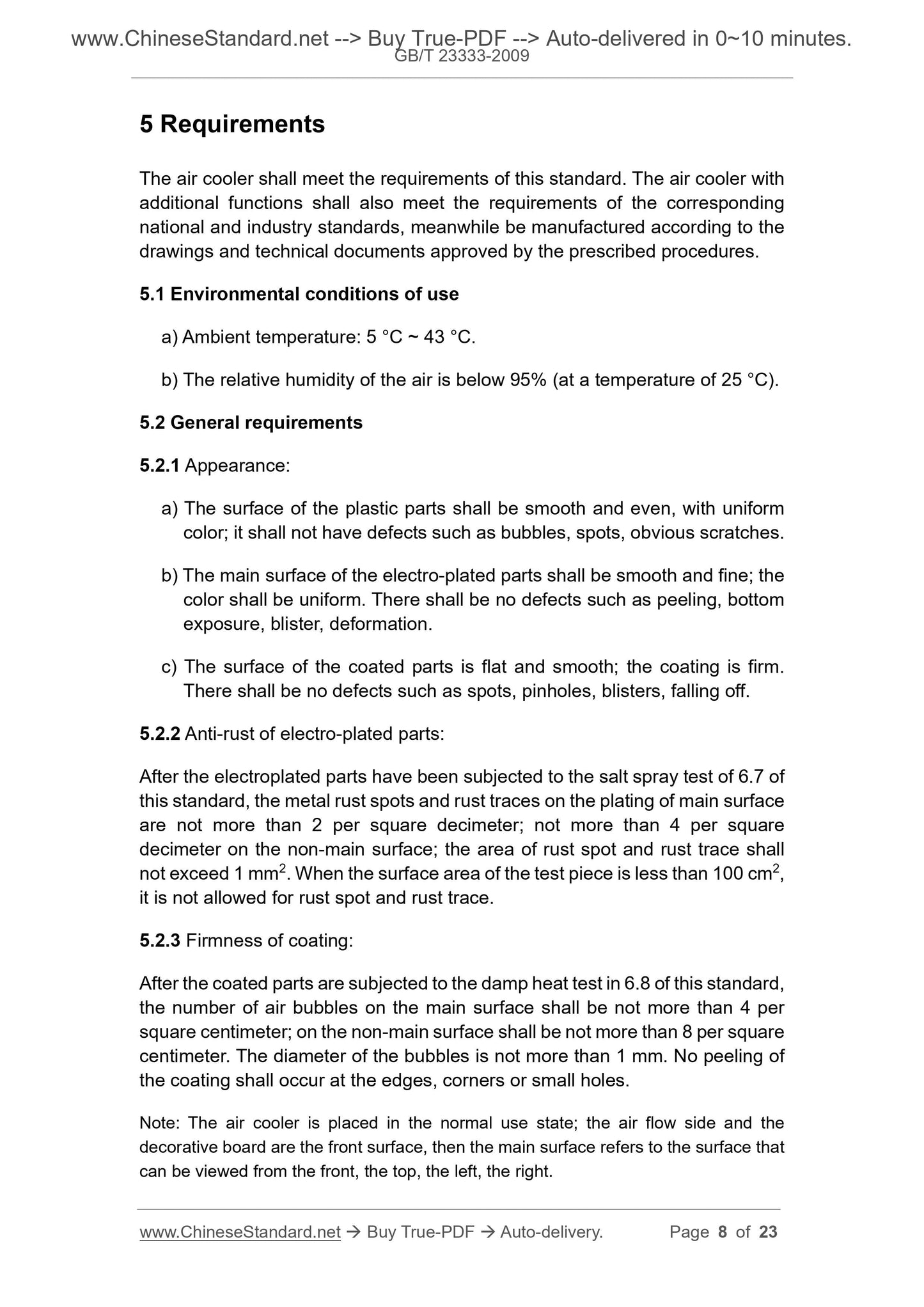

This standard specifies the terms and definitions, classification and modelnaming, requirements, test methods, inspection rules, marking, packaging,

transportation and storage of evaporative air cooler for household and similar

use (hereinafter referred to as "air cooler").

This standard applies to the air cooler which has a rated voltage of single-phase

appliance of not more than 250 V, a rated voltage of other appliances of not

more than 480 V, cools the air by the evaporative heat absorption principle of

water, is used for household and similar places.

This standard does not apply to:

- Air cooler designed only for industrial use;

- Air cooler intended to use in a special environment where corrosive or

explosive gases (such as dust, steam or gas) are often generated.

Basic Data

| Standard ID | GB/T 23333-2009 (GB/T23333-2009) |

| Description (Translated English) | Evaporative air cooler |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | Y61 |

| Classification of International Standard | 23.120 |

| Word Count Estimation | 15,176 |

| Date of Issue | 2009-03-19 |

| Date of Implementation | 2009-11-01 |

| Regulation (derived from) | National Standard Approval Announcement 2009 No.3 (Total No.143) |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the household and similar purposes evaporative cooling fan (hereinafter referred to as " cooling fan ") terms and definitions, classification and model name, requirements, test methods, inspection rules, signs, packaging, transport and storage. This standard applies to single-phase appliances rated voltage not exceeding 250V, other appliances rated voltage not exceeding 480V, absorbs heat through evaporation of water to cool the air principle, cooling fan in the family and similar use. This standard does not apply exclusively designed for industrial use cooling fan, intended for use in a corrosive or explosive gases (such as dust, steam or gas) cooling fan locations where special conditions. |

Share