1

/

of

8

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 23263-2009 English PDF (GB/T23263-2009)

GB/T 23263-2009 English PDF (GB/T23263-2009)

Regular price

$145.00

Regular price

Sale price

$145.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 23263-2009: Determination of asbestos in products

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 23263-2009 (Self-service in 1-minute)

Newer / historical versions: GB/T 23263-2009

Preview True-PDF

Scope

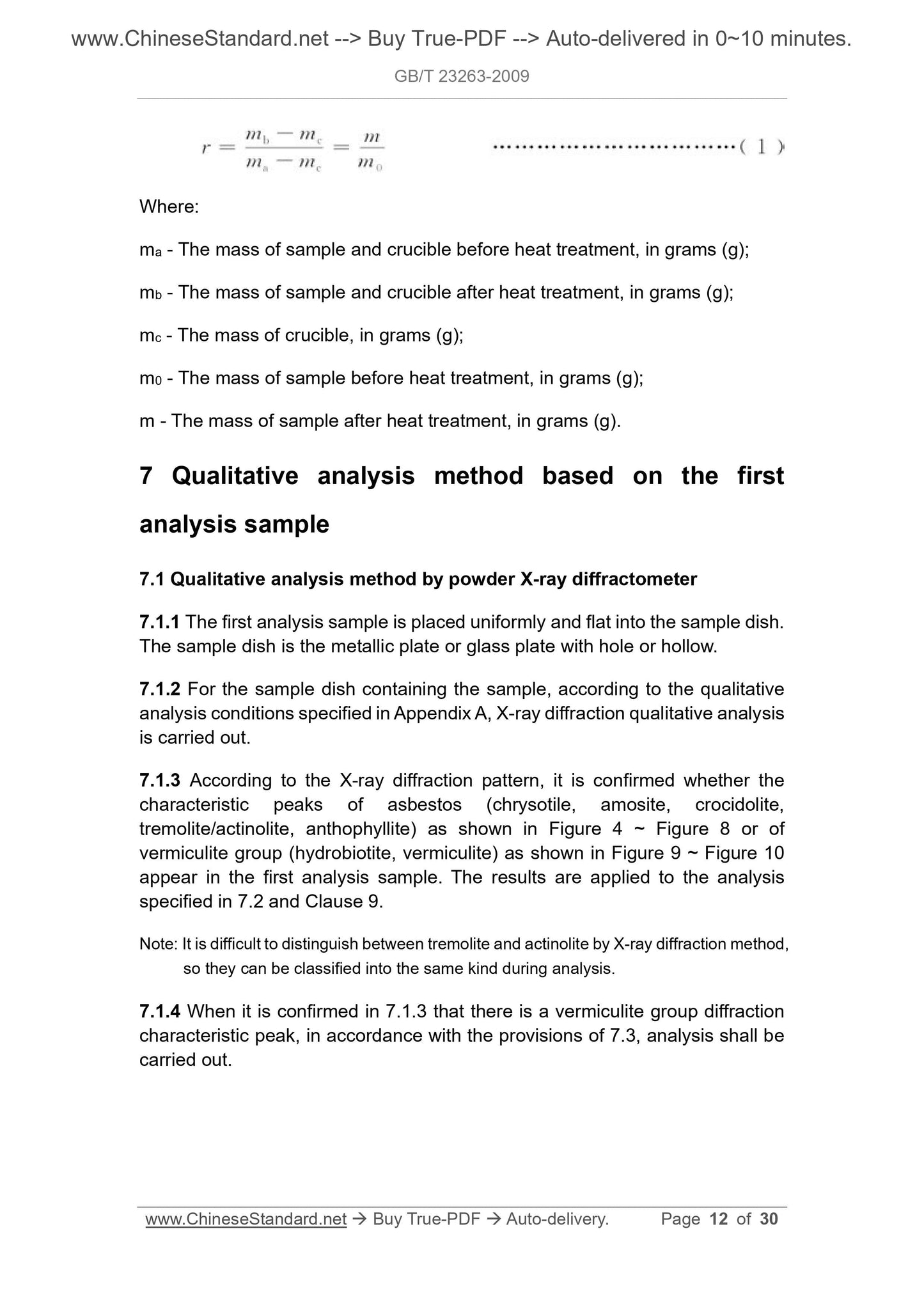

This Standard specifies the test method for the determination of asbestos inproducts using powder X-ray diffractometer and polarizing microscope.

This Standard applies to the determination of asbestos in building materials,

friction materials, sealing materials, heat insulating materials, and non-metallic

minerals.

Basic Data

| Standard ID | GB/T 23263-2009 (GB/T23263-2009) |

| Description (Translated English) | Determination of asbestos in products |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | Q61 |

| Classification of International Standard | 73.080 |

| Word Count Estimation | 18,128 |

| Date of Issue | 2009-03-09 |

| Date of Implementation | 2009-11-05 |

| Quoted Standard | GB 10736; GB/T 15896; HG/T 2892 |

| Adopted Standard | JIS A1481-2008, NEQ |

| Regulation (derived from) | National Standard Approval Announcement 2009 No.2 (Total No.142) |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies test methods using powder X -ray diffraction and polarized light microscopy determination of asbestos content in products. This standard applies to construction materials, friction materials, sealing materials, determination of insulation materials and non-metallic mineral asbestos content. |

Share