1

/

of

8

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 22905-2008 English PDF (GB/T22905-2008)

GB/T 22905-2008 English PDF (GB/T22905-2008)

Regular price

$220.00

Regular price

Sale price

$220.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 22905-2008: Superabsorbent polymer for diaper

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 22905-2008 (Self-service in 1-minute)

Newer / historical versions: GB/T 22905-2008

Preview True-PDF

Scope

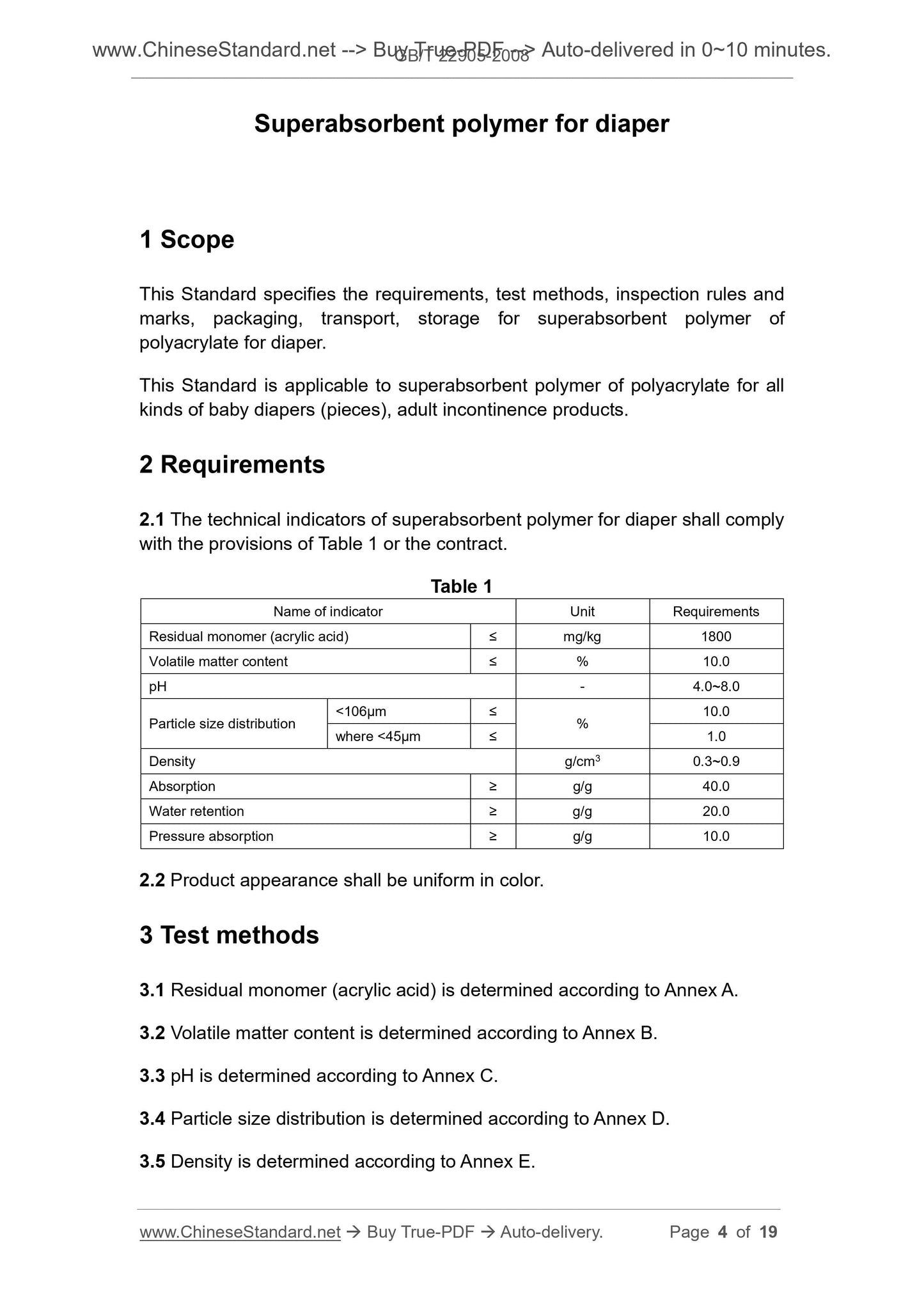

This Standard specifies the requirements, test methods, inspection rules andmarks, packaging, transport, storage for superabsorbent polymer of

polyacrylate for diaper.

This Standard is applicable to superabsorbent polymer of polyacrylate for all

kinds of baby diapers (pieces), adult incontinence products.

Basic Data

| Standard ID | GB/T 22905-2008 (GB/T22905-2008) |

| Description (Translated English) | Superabsorbent polymer for diaper |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | Y39 |

| Classification of International Standard | 85.080 |

| Word Count Estimation | 12,136 |

| Date of Issue | 2008-12-30 |

| Date of Implementation | 2009-09-01 |

| Regulation (derived from) | National Standard Approval Announcement 2008 No.25 (Total No.138) |

| Issuing agency(ies) | General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China |

| Summary | This standard specifies the requirements for diapers polyacrylate superabsorbent resin, test methods, inspection rules and signs, packaging, transport and storage. This standard applies to all types of baby diapers (tablets), adult incontinence products polyacrylate super-absorbent resin. |

Share